Multifunctional colored pencil core and preparation method thereof

A multi-functional, pencil lead technology, applied in pencil lead, non-moving pencil, printing and other directions, can solve the problems of alternate use, graphite lead and water-soluble color lead can not be used, etc., to achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

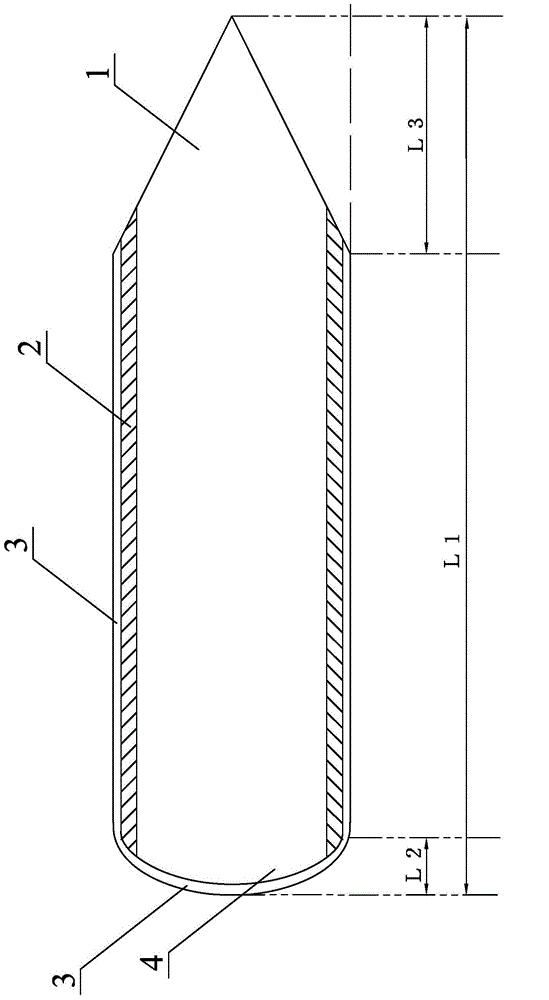

Image

Examples

Embodiment 1

[0022] A multifunctional colored pencil lead, prepared from the following raw materials in mass percentage: 10% clay with a water content of 40%, 40% fine talc powder of 1250 mesh, 20% calcium stearate, 10% Tween, permanent Violet 4%, sodium carboxymethylcellulose 6% and No. 90 microfine wax 10%.

Embodiment 2

[0024] A method for preparing a multifunctional colored pencil lead, comprising the steps of:

[0025] (A) Washed clay with a water content of 40%, 1250 mesh fine talcum powder, stearate, magnesium stearate, green lotus, sodium carboxymethylcellulose and No. 90 heated to 180° The micro-fine wax is mixed according to the mass ratio of 5:20:10:5:2:3:5 and then put into the mixer. Set the speed of the mixer to 1500r / min, stir for 6 hours, and make a core material with a water content of 6%.

[0026] (B) Put the stirred core material into a three-roll mill and grind it to make a 180-mesh core material; after sealing and storing the ground core material for 48 hours, it is divided into 4 times and added with a pressure of 400 tons. Squeeze in the core pressing machine, and be pressed into the multifunctional colored pencil lead pre-finished product that diameter is 2.2mm, and length is 22cm; The lead core that described pressing is put into drying core furnace, under the condition ...

Embodiment 3

[0028] A method for preparing a multifunctional colored pencil lead, comprising the steps of:

[0029] (A) Washed clay with a water content of 40%, 1250 mesh fine talcum powder, stearate, magnesium stearate, green lotus, sodium carboxymethylcellulose and No. 90 heated to 180° The micro-fine wax is mixed according to the mass ratio of 5:20:10:5:2:3:5 and put into the mixer. Set the speed of the mixer to 2000r / min and stir for 6 hours to make a core with a water content of 6% to 8%. material;

[0030] (B) Put the stirred core material into a three-roll mill and grind it to make a 200-mesh core material; after sealing and storing the ground core material for 48 hours, it is divided into 4 times and added with a pressure of 500 tons. Squeeze in the core pressing machine, and be pressed into the multifunctional colored pencil lead pre-finished product that diameter is 8.0mm, and length is 22cm; The lead core that described pressing is packed into core drying oven, under the condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com