Plastic product surface imitation metal automatic wire-drawing device and process

A metal-like and wire-drawing technology, applied in automatic grinding control devices, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the wire-drawing effect, easy to fill with paint, and easy to touch and damage the wire, so as to avoid product scrap, Reduce production cost and improve the effect of drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

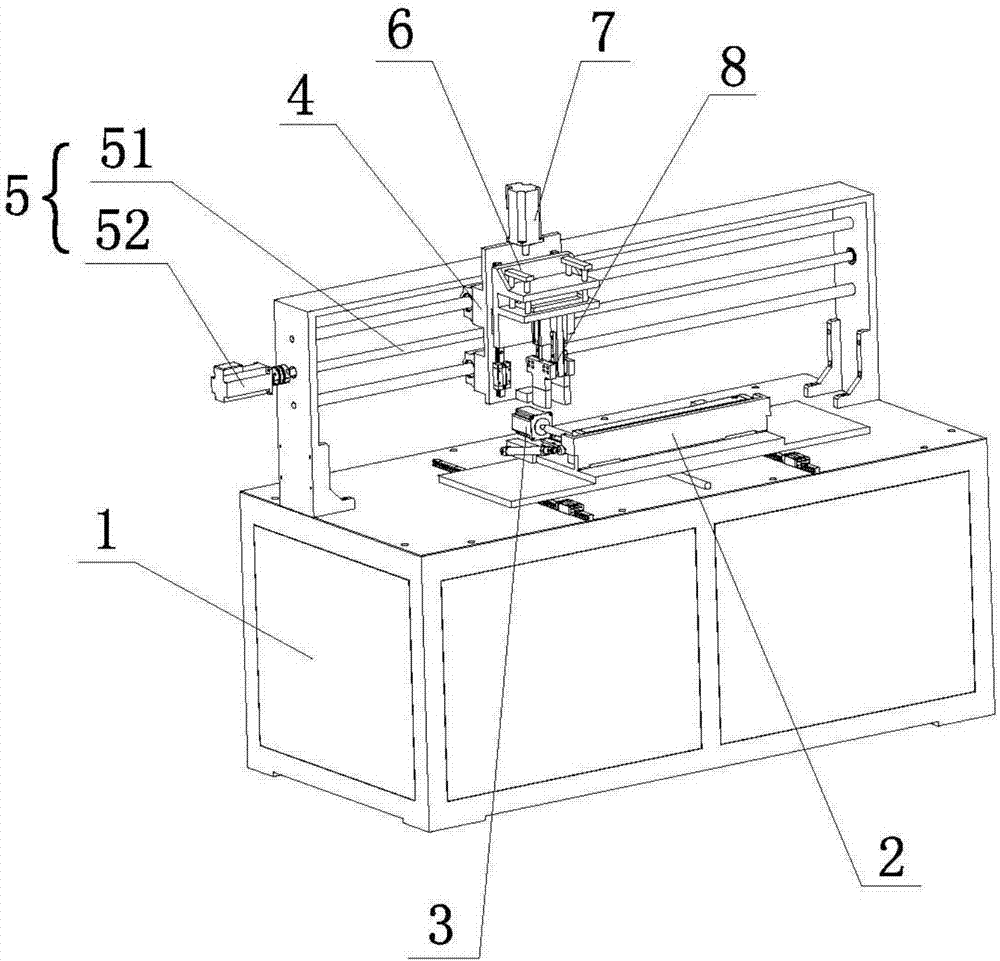

[0021] Attached below Figure 2 to Figure 5 , and specific embodiments will further illustrate the present invention.

[0022] like image 3 As shown, an automatic wire drawing device imitating metal on the surface of plastic products includes a machine table 1, and the upper end of the machine table 1 is provided with a clamp 2 for placing plastic products and a first drive for driving the clamp 2 to move along the Y-axis direction Mechanism 3, a wire drawing device is provided above the clamp 2, and the wire drawing device includes a first sliding table 4 and a second driving mechanism 5 that drives the first sliding table 4 to slide laterally along the X-axis direction, and the first sliding table 4. A second sliding table 6 and a third drive mechanism 7 for driving the second sliding table 6 to slide up and down along the Z-axis direction are provided, and the third sliding table 6 is provided with a wire drawing mechanism 8.

[0023] In this embodiment, the plastic prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com