A plastic product manufacturing method and a product of the method

A manufacturing method and product technology, applied to the manufacturing method of plastic products and its products, can solve the problems of less than 40% yield rate, unimprovable yield rate, and difficult control, etc., to achieve short manufacturing process, environmentally friendly manufacturing process, and avoid paint falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, method steps and effects of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

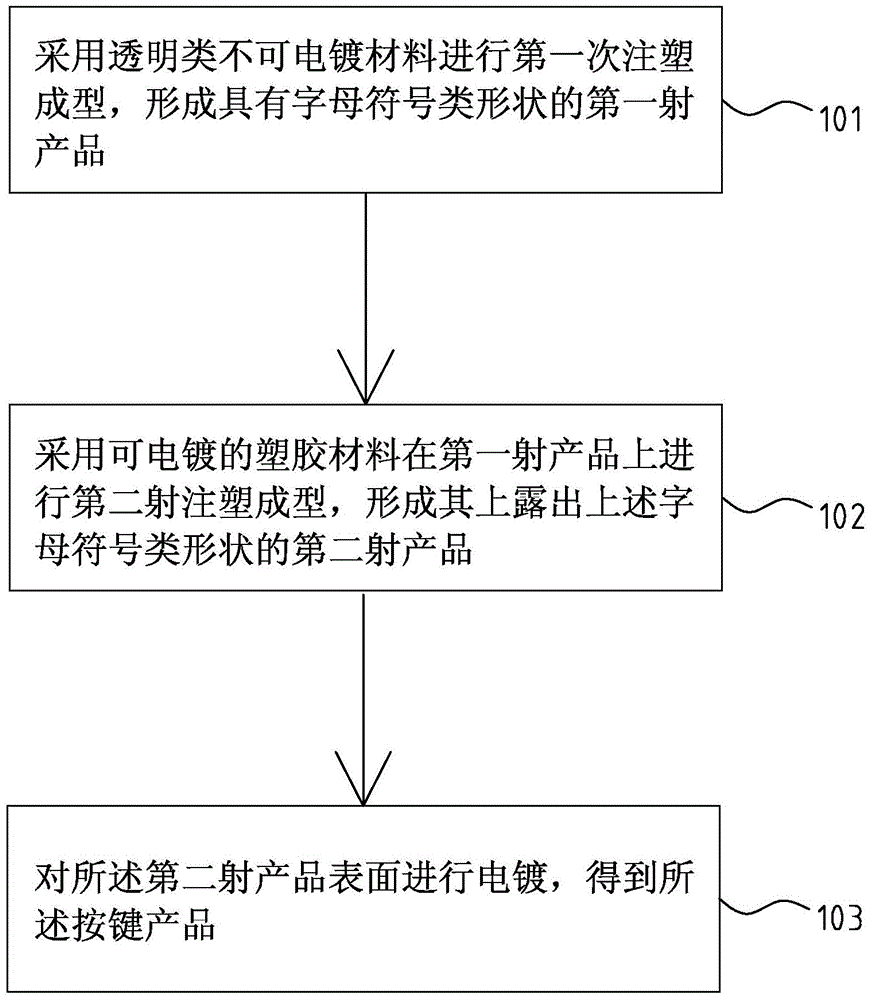

[0028] Please refer to image 3 , image 3 It is a flow chart of the manufacturing method of the plastic product of the present invention.

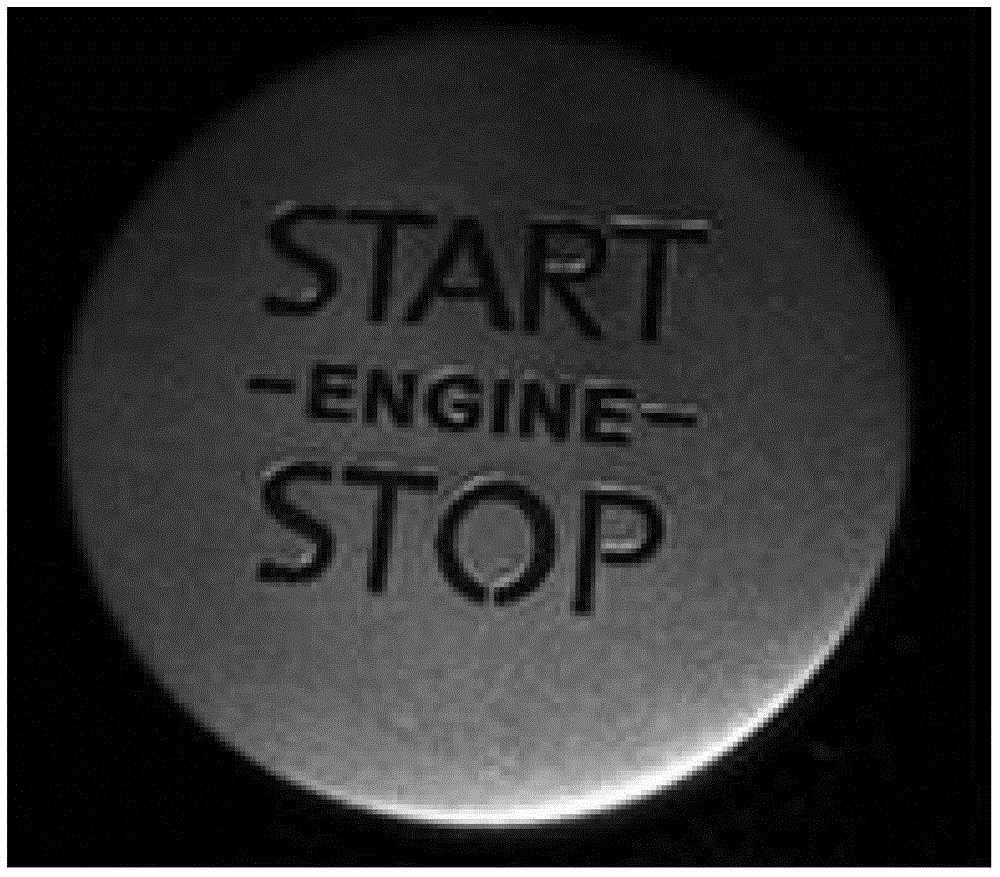

[0029] In order to achieve the above object, the manufacturing method of the plastic product of the present invention, the product is a letter symbol type button product, the method comprises the following steps:

[0030] Step 101: Using the first shot material to perform the first shot injection molding to form the first shot product, the first shot product has a shape of a letter symbol, wherein the first shot material is a transparent non-electroplateable material, using Transparent materials can make the light source placed under it, and the light can be transmitted;

[0031] Step 102: Carry out second injection molding on the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com