Machine room pipeline equipment integration group splicing method

An integrated group and pipeline technology, applied in mechanical equipment, flange connections, workpiece clamping devices, etc., can solve problems such as unfavorable pipeline accuracy, increase people's working time, increase people's labor intensity, etc., and reduce the operation time. time, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

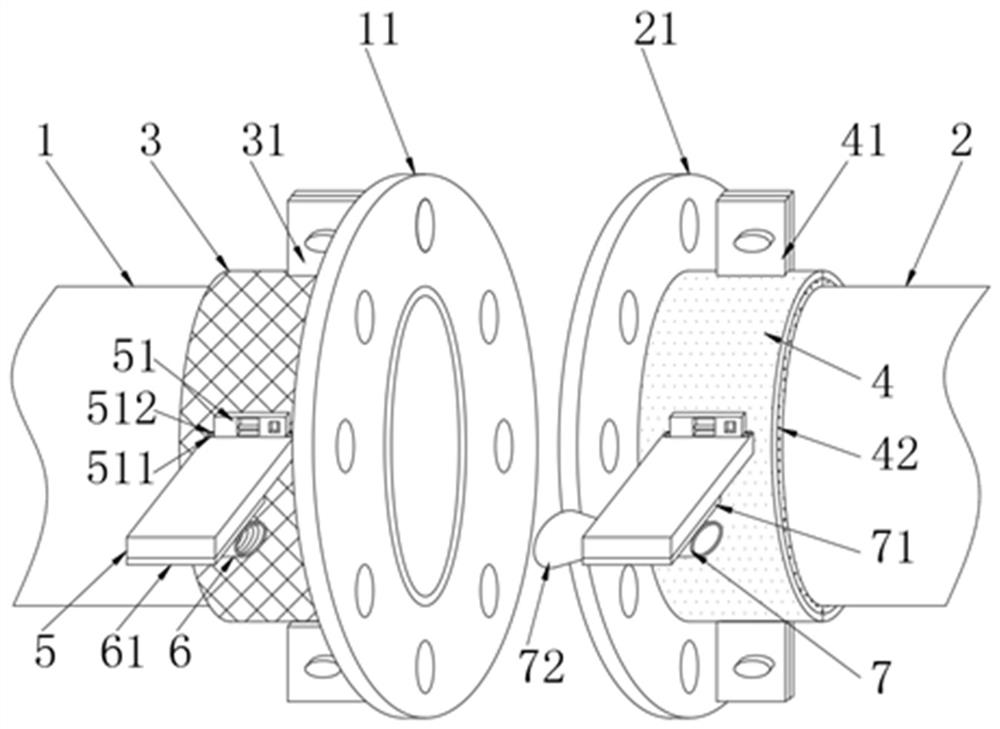

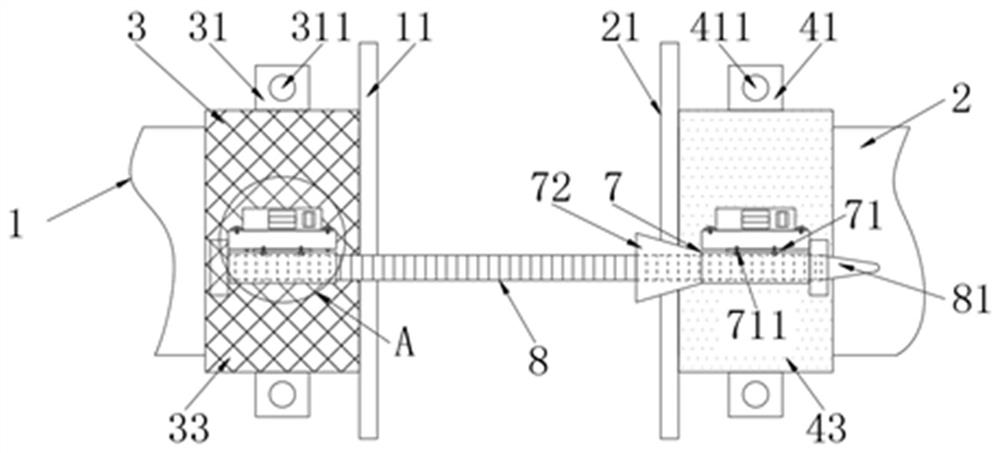

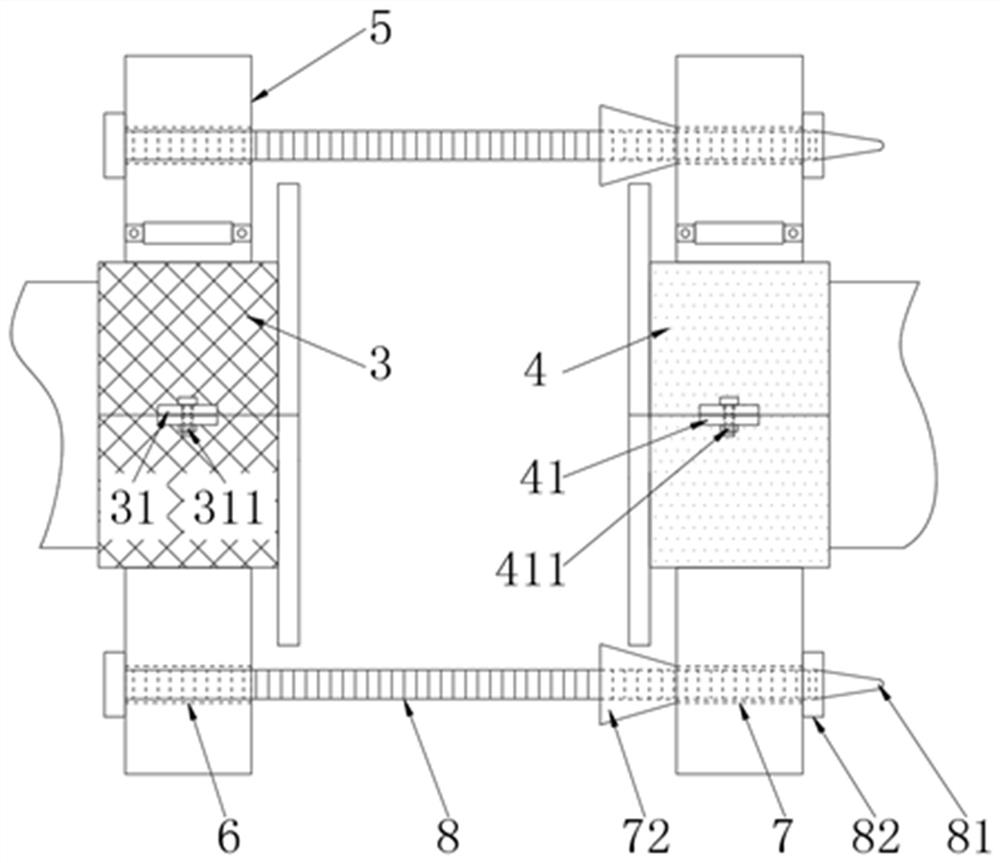

[0030] see Figure 1-7 , in an embodiment of the present invention, a method for assembling an integrated group of pipeline equipment in a machine room specifically includes the following steps:

[0031] Step 1: Align the first clamp (3) and the second clamp ( 4) To install, use the small level ruler (51) to observe the deviation during installation and adjust it in time, so that the center of circle of the threaded sleeve (6) and the limit tube (7) are on the same straight line.

[0032] Step 2: Insert two high-strength threaded rods (8) into the limit tube (7), through the horn-shaped design of the entry tube (72), it is convenient for the high-strength threaded rods (8) to enter the limit tube (7) Inside, screw the high-strength nuts (82) on each high-strength threaded rod (8) at the same time, so as to slowly pull the distance between the first pipe (1) and the second pipe (2) that need to be connected close, so that the first connecting flange (11) and the second connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com