Crystallized glass article having patterns and method of producing the same

A technology of crystallized glass and crystalline glass, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve problems such as affecting the aesthetics of floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

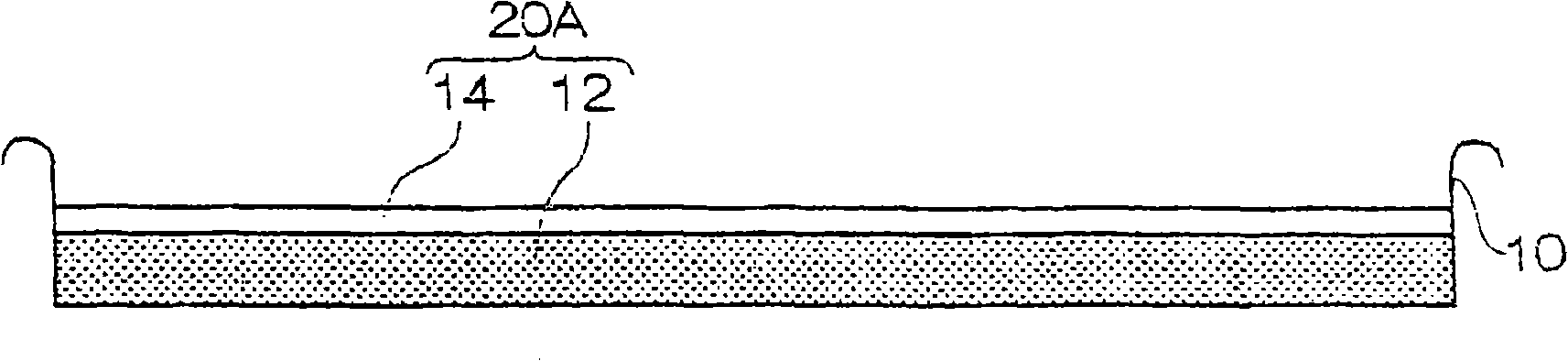

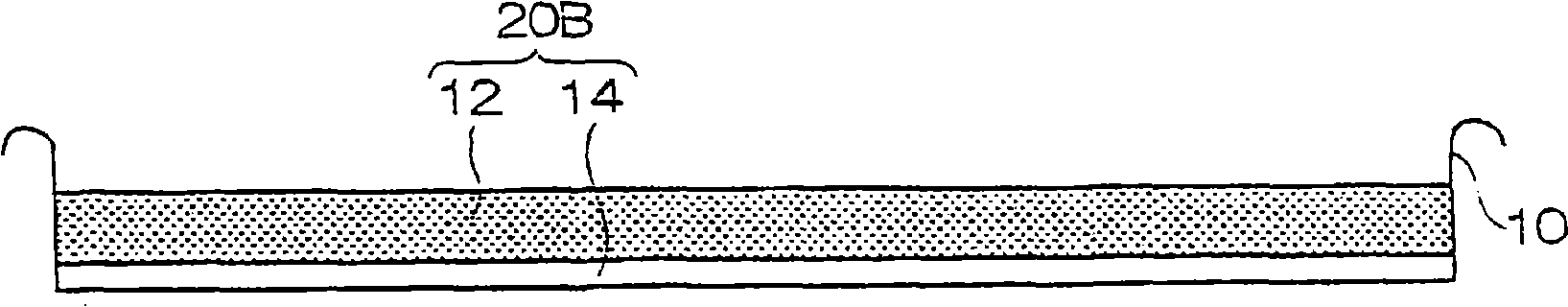

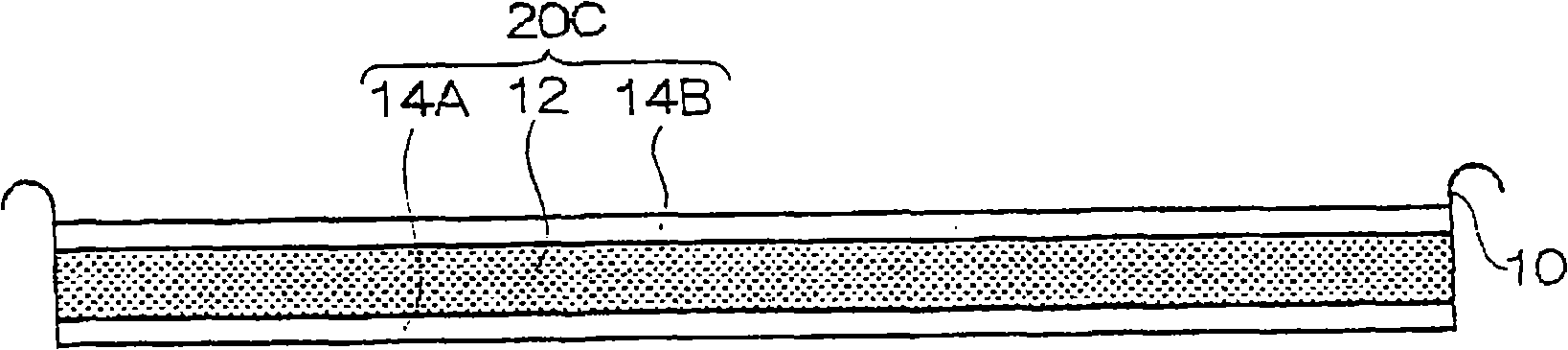

Method used

Image

Examples

Embodiment 1

[0123] First, for the mass percentage of SiO 2 : 65.1%, Al 2 o 3 : 6.6%, CaO: 12.0%, Na 2 O: 3.3%, K 2 O: 2.3%, BaO: 4.1%, and ZnO: 6.6% of glass raw materials composed of 1500 ° C × 16 hours of melting treatment, the molten glass is quenched in water to become glass cullets, and the glass cullets are dried and classified, and then Crystalline glass bodies with a particle diameter of 1 to 3 mm can be obtained. These crystalline glass bodies can become β-wollastonite as the main crystal after heat treatment, and the thermal expansion coefficient is 65×10 in the temperature range of 30-380°C. -7 / °C white crystallized glass.

[0124] Secondly, for the mass percentage of SiO 2 : 65.1%, Al 2 o 3 : 6.6%, CaO: 12.0%, Na 2 O: 3.3%, K 2 The glass raw material composed of O: 2.3%, BaO: 4.1%, and ZnO: 6.6% is melted at 1500° C. for 16 hours, and then formed into a sheet by roll pressing to obtain a crystalline glass sheet with a thickness of 5 mm. This crystalline glass plate...

Embodiment 2

[0131] First, for the mass percentage of SiO 2 : 65.1%, Al 2 o 3 : 6.6%, CaO: 12.0%, Na 2 O: 3.3%, K 2 O: 2.3%, BaO: 4.1%, and ZnO: 6.6% of glass raw materials composed of 1500 ° C × 16 hours of melting treatment, the molten glass is quenched in water to become glass cullets, and the glass cullets are dried and classified, and then Crystalline glass bodies with a particle diameter of 1-3 mm can be obtained. These crystalline glass bodies can become β-wollastonite as the main crystal after heat treatment, and the thermal expansion coefficient is 65×10 in the temperature range of 30-380°C. -7 / °C white crystallized glass.

[0132] Secondly, for the mass percentage of SiO 2 : 65.1%, Al 2 o 3 : 6.6%, CaO: 12.0%, Na 2 O: 3.3%, K 2 The glass raw material composed of O: 2.3%, BaO: 4.1%, and ZnO: 6.6% is melted at 1500° C. for 16 hours, and then formed into a plate by a rolling method to obtain a crystalline glass plate with a thickness of 5 mm. This crystalline glass plate...

Embodiment 3

[0139] First, for the mass percentage of SiO 2 : 62.2%, Al 2 o 3 : 5.9%, CaO: 13.0%, Na 2 O: 4.5%, K 2 O: 2.1%, Li 2 O: 1.0%, BaO: 6.0%, ZnO: 5.2%, and NiO: 0.1% of glass raw materials composed of 1450 ° C × 16 hours of melting treatment, the molten glass is quenched in water to become glass cullet, and the glass cullet After drying and classification, crystalline glass bodies with a particle size of 3-7 mm can be obtained. These crystalline glass bodies can become β-wollastonite as the main crystal after heat treatment, and the thermal expansion coefficient is 69×10 in the temperature range of 30-380°C. -7 / ℃ beige crystallized glass.

[0140] Secondly, for the mass percentage of SiO 2 : 62.2%, Al 2 o 3 : 5.9%, CaO: 13.0%, Na 2 O: 4.5%, K 2 O: 2.1%, Li 2 O: 1.0%, BaO: 6.0%, ZnO: 5.2%, and NiO: 0.1% glass raw materials are melted at 1450°C for 16 hours, and then formed into a plate by a roll method, and then a 3mm thick glass can be obtained. Crystalline glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com