Method for producing architectural ceramic from red mud

A technology of architectural ceramics and red mud, which is applied in the production and application of ceramic materials, household appliances, etc., which can solve the problems of environmental pollution, land occupation, and insufficient and effective utilization of red mud, and achieve the effect of reducing production costs and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

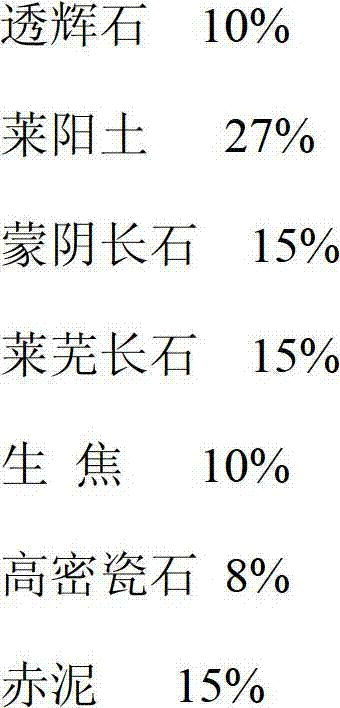

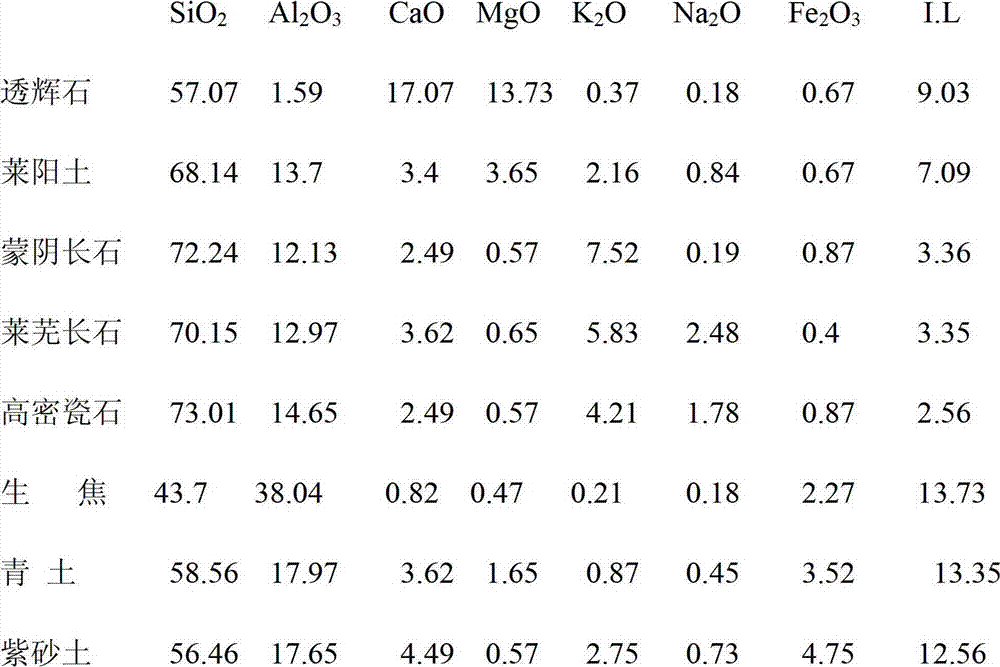

[0020] Antique bricks produced from red mud are composed of the following raw materials in mass percentages:

[0021]

[0022] In addition, add 5% waste blanks of the mass sum of the above-mentioned materials.

[0023] Before using the waste billet, the waste billet is crushed into particles with a diameter of less than 2cm.

[0024] The raw materials are mixed and ground, and the grinding fineness of the mud is 250 mesh sieve, the remaining 5%, the firing temperature: 1170°C, and the firing cycle: 40 minutes.

[0025] Product testing indicators are as follows.

[0026] Product implementation standard: Appendix K of GB / T4100—2006, tested by the Bureau of Technical Supervision, the actual test data are as follows:

[0027]

[0028] According to this formula to make small cakes, the degree of sintering is high, and the color of the body after firing is dark red, which is darker than the red brick antique brick produced with purple sand soil, without deformation. Accordin...

Embodiment 2

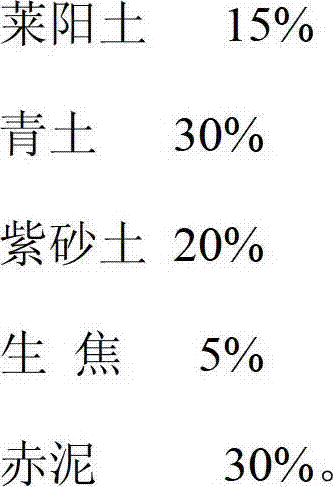

[0030] Western-style tiles or cylinder tiles produced from red mud are composed of the following raw materials in mass percentages:

[0031]

[0032] The raw materials are mixed and ground, and the grinding fineness of the mud is 12% of the 250-mesh sieve. The firing temperature: 1100°C, and the firing cycle: 30 minutes.

[0033] According to this formula, make small cakes for trial firing, the color is brighter than the original product, the degree of sintering is high, and there is no deformation. This formula is used for production, and the production process parameters are controlled according to the original parameters. After testing, the products fully meet the national standards.

[0034] Due to the low temperature strength of red mud itself, the product has sufficient high temperature strength during the firing process by adjusting the process formula, the color of the green body produced is more vivid than the previous color, and all physical and chemical indicator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com