Composite bismuth vanadium photocatalyst supported by cobalt oxide and preparation method thereof

A technology of bismuth vanadate and cobalt oxide, which is applied in the field of bismuth vanadate composite photocatalyst and its preparation, can solve the problems that the activity of bismuth vanadate is not suitable for practical application, etc., and achieve the goal of promoting practical application, reducing cost, and high-efficiency photocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 9.5g of bismuth nitrate and 2.3396g of ammonium metavanadate, dissolve them with 25ml and 75ml of 1.84M nitric acid respectively, then mix them together, add 3.75g of urea, stir and dissolve, place in an oil bath at 90°C for 8 hours, the resulting precipitate was centrifuged, washed with deionized water until neutral, then washed three times with absolute ethanol, and dried in an oven at 80°C for 24 hours. Weigh 1 g of the bismuth vanadate powder prepared by the above method with a small evaporating dish, add 2 ml of 19.42 g / L cobalt nitrate prepared with deionized water, stir evenly, place in a constant temperature oven and dry at 80°C for 24 hours, then After being ground into powder, it was placed in a muffle furnace and baked at 300° C. for 2 hours to obtain a cobalt oxide-supported bismuth vanadate composite photocatalyst responding to visible light.

[0027] The morphology of the prepared composite photocatalyst under the transmission electron microscope is ...

Embodiment 2

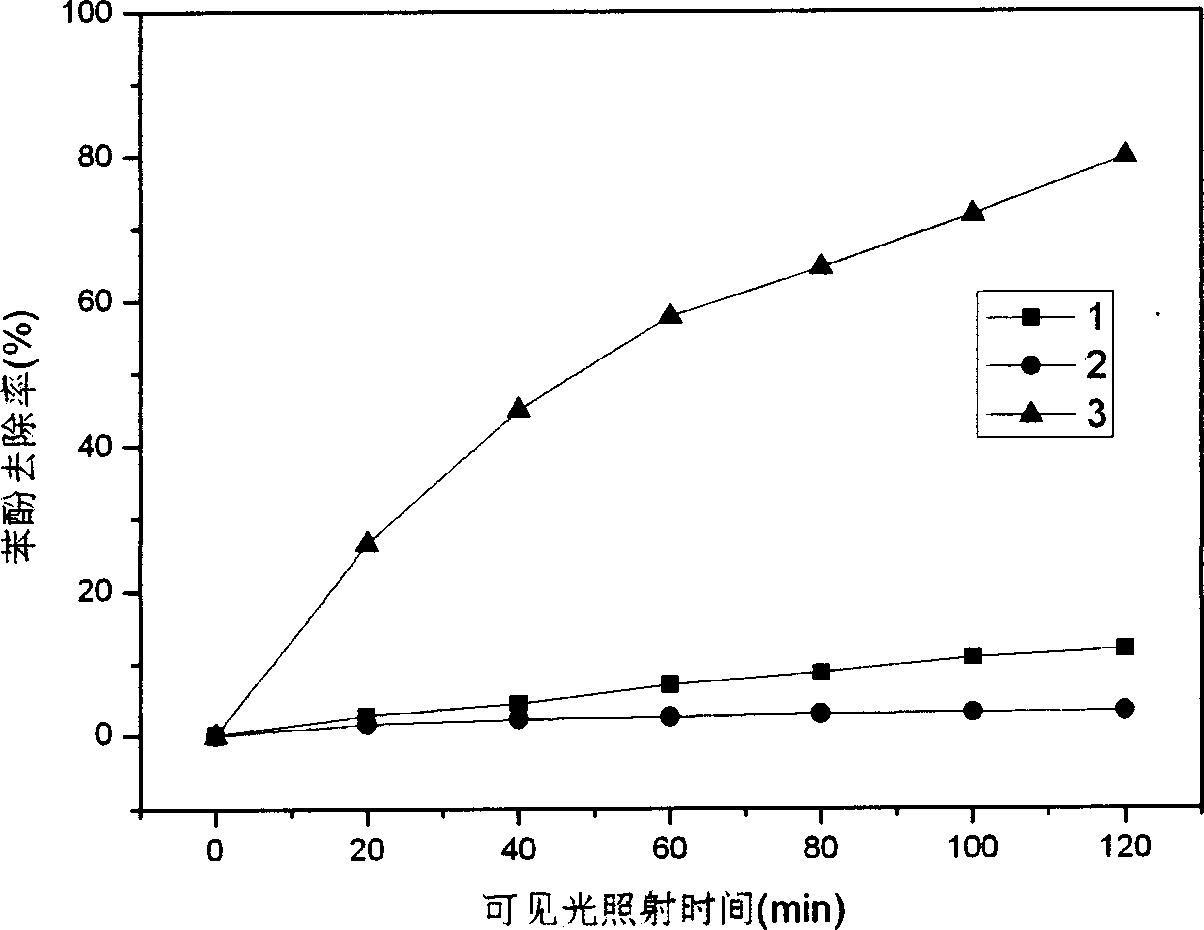

[0031] Weigh 4.8507g of bismuth nitrate and 1.1698g of ammonium metavanadate, dissolve them with 25ml of 1.84M nitric acid respectively, then mix them together, add 1.875g of urea, stir and dissolve, place in an oil bath at 90°C for 8 hours at a constant temperature, The resulting precipitate was centrifuged, washed with deionized water until neutral, then washed three times with absolute ethanol, and dried in an oven at 60°C for 48 hours. Weigh 2 g of bismuth vanadate powder prepared by the above method with a small evaporating dish, add 4 ml of 19.42 g / L cobalt nitrate prepared with absolute ethanol, stir evenly, place in a constant temperature oven and dry at 80°C for 24 hours, then After being ground into powder, it was placed in a muffle furnace and baked at 200° C. for 2 hours to obtain a cobalt oxide-loaded bismuth vanadate composite photocatalyst responsive to visible light. The performance test results of phenol degradation: under the irradiation of visible light with...

Embodiment 3

[0033] Weigh 4.8507g of bismuth nitrate and dissolve it with 50ml of 1.84M nitric acid, then add 1.1698g of ammonium metavanadate, mix well, add 1.875g of urea, stir and dissolve, place in an oil bath at 90°C for 8 hours at a constant temperature to form The precipitate was centrifuged, washed with deionized water until neutral, washed three times with absolute ethanol, and dried in an oven at 80°C for 24 hours. Weigh 1 g of bismuth vanadate powder prepared by the above method with a small evaporating dish, add 4 ml of 19.42 g / L cobalt nitrate prepared with deionized water, stir evenly, place in a constant temperature oven and dry at 80°C for 12 hours, then After being ground into powder, it was placed in a muffle furnace and baked at 300° C. for 2 hours to obtain a cobalt oxide-loaded bismuth vanadate composite photocatalyst responsive to visible light. The performance test results of phenol degradation: under the irradiation of visible light with a wavelength greater than 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com