Surface active agent assisting alcohol-hydrothermal method for preparing anthoid BiVO4

A technology of surfactant and hydrothermal method, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., to achieve the effect of simple process, cheap raw materials, and controllable crystal phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

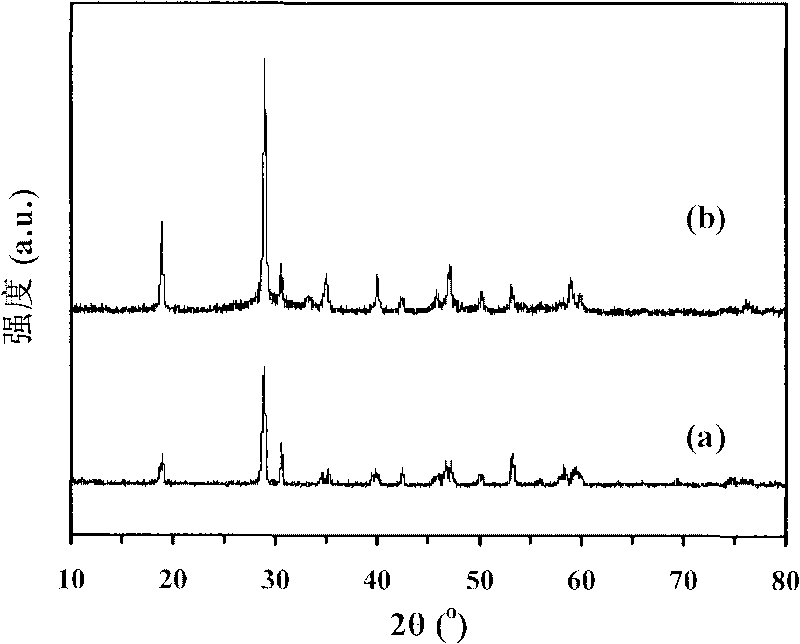

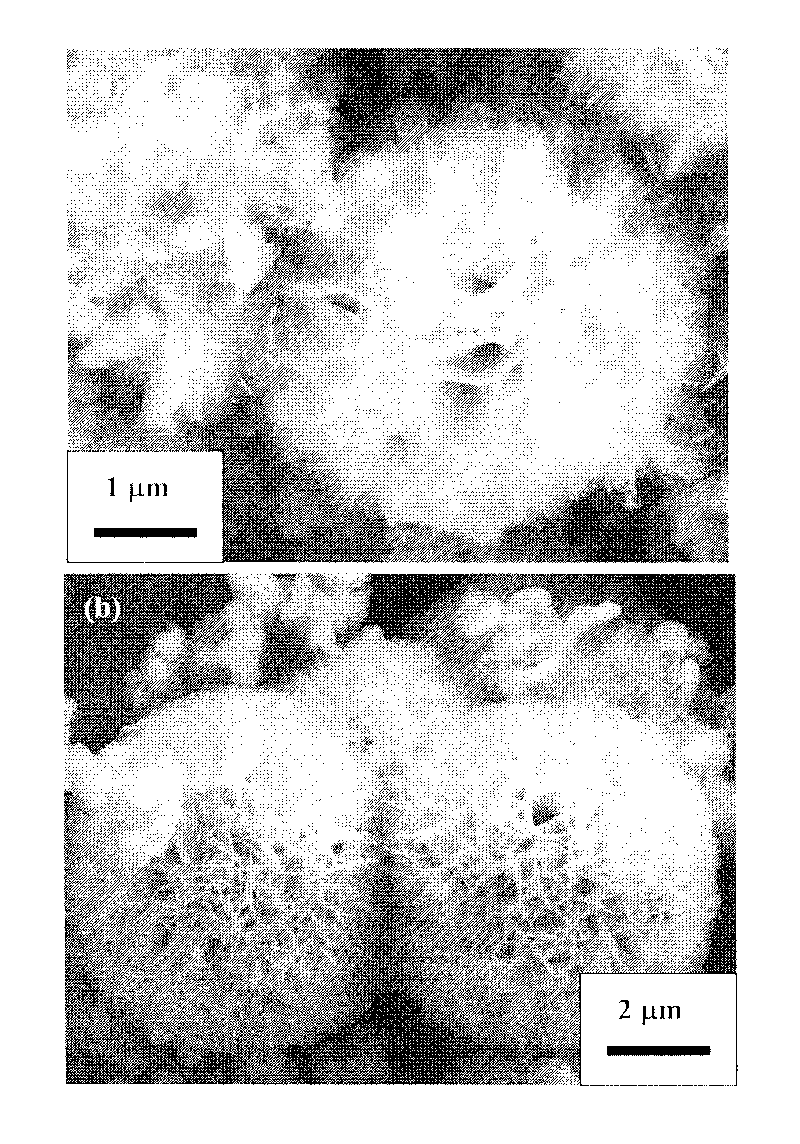

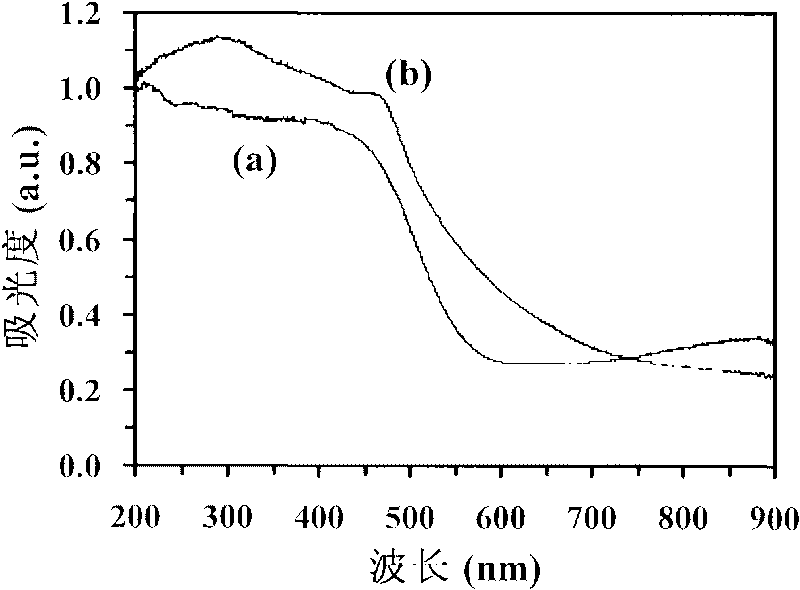

[0015] Example 1: Under stirring conditions, to ethanol: ethylene glycol: concentrated HNO 3 (concentration is 67%) add 30mmol surfactant cetylpyridinium chloride in the mixed solution (total volume is 62.5mL) that volume ratio is 12:12:1, wait to mix again and add 10mmolBi(NO 3 ) 3 ·5H 2 O powder and 10 mmol NH 4 VO 3 powder, after continuing to stir evenly, add an appropriate amount of NaOH powder to adjust the pH value of the solution to 3. Transfer the above mixed solution to a 100mL stainless steel autoclave lined with polytetrafluoroethylene (volume filling degree is 63%), and place it in an incubator for 12 hours of constant temperature alcohol-hydrothermal treatment at 100°C, take it out and let it naturally After cooling to room temperature, the resulting product was filtered, washed three times with deionized water and three times with absolute ethanol, and dried at 60 °C for 12 h to obtain flower-like BiVO with a monoclinic scheelite structure. 4 Particles, abo...

Embodiment 2

[0016] Embodiment 2: Under stirring condition, to ethanol: ethylene glycol: concentrated HNO 3 (Concentration is 67%) Add 30mmol surfactant cetylpyridinium chloride in the mixed solution (total volume is 62.5mL) that the volume ratio is 12:12:1, after treating to mix evenly, add 10mmolBi(NO 3 ) 3 ·5H 2 O powder and 10 mmol NH 4 VO 3 powder, after continuing to stir evenly, add an appropriate amount of NaOH powder to adjust the pH value of the solution to 7. Transfer the above mixed solution to a 100mL stainless steel autoclave lined with polytetrafluoroethylene (volume filling degree is 63%), and place it in an incubator for 12 hours of constant temperature alcohol-hydrothermal treatment at 100°C, take it out and let it naturally After cooling to room temperature, the resulting product was filtered, washed three times with deionized water and three times with absolute ethanol, and dried at 60 °C for 12 h to obtain flower-like BiVO with a monoclinic scheelite structure. 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com