Organic solvent-water heating method for preparing football-shaped mesoporous BiVO4

An organic solvent, football-shaped technology, applied in inorganic chemistry, chemical instruments and methods, vanadium compounds, etc., to achieve the effects of controllable crystal phase structure, excellent application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

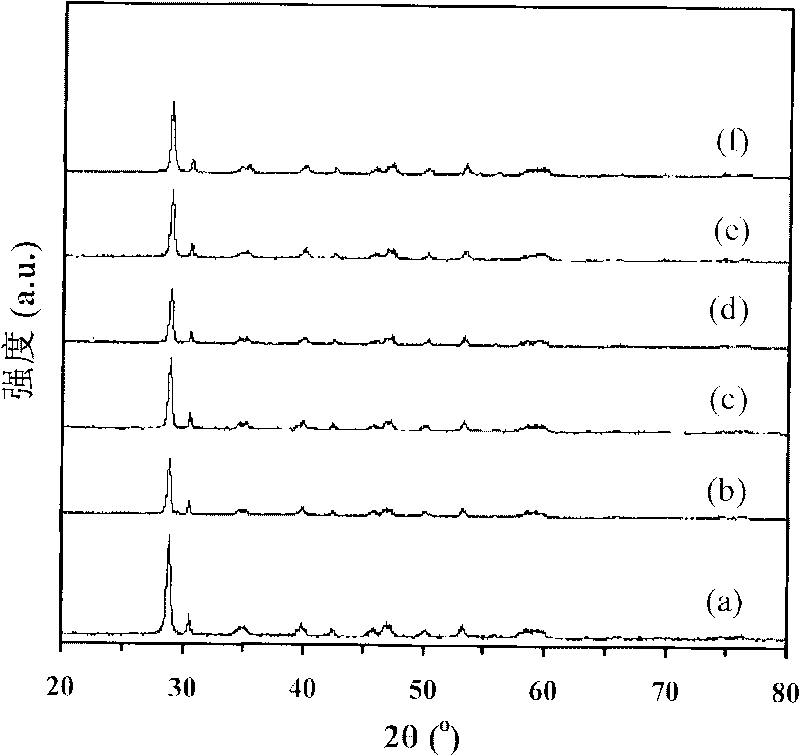

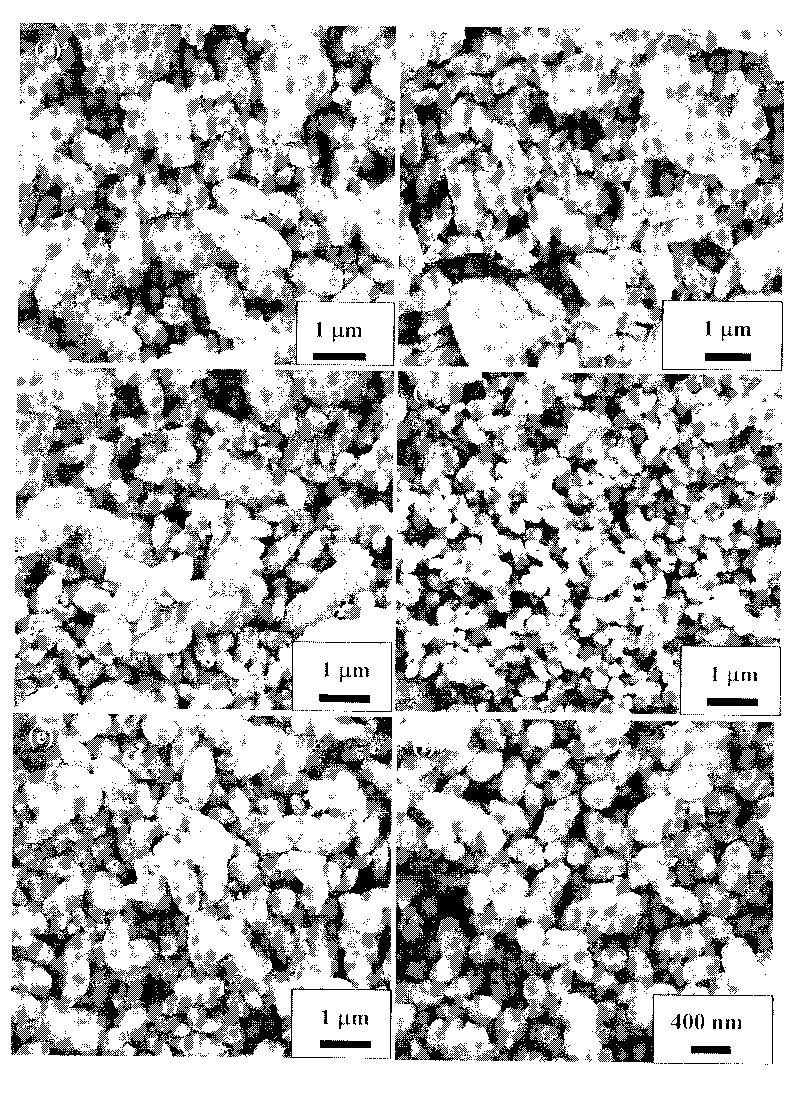

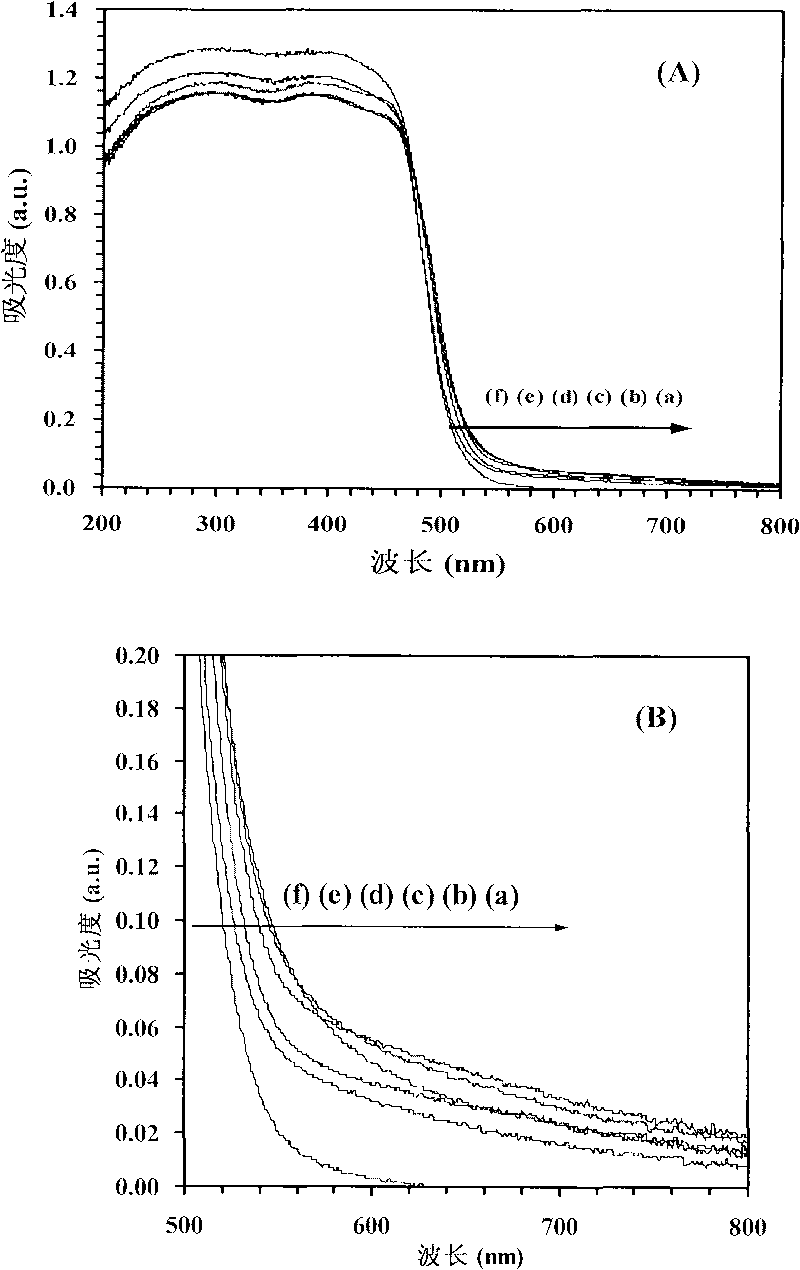

Embodiment 1

[0016] Example 1: Under stirring conditions, to ethanol with a volume ratio of 5:5:1: ethylene glycol: concentrated HNO 3 (concentration is 67wt%) in the mixed solution (total volume is 55mL) add 30mmol dodecylamine, after treating to mix uniformly, add 10mmol Bi(NO 3 ) 3 ·5H 2 O powder and 10 mmol NH 4 VO 3 Powder, adjust the pH of the solution to 1.5 with ethanol and ethylene glycol sodium hydroxide (2mol / L) alcohol solution with a volume ratio of 1:1, and transfer the above mixed solution to a 100mL stainless steel self-pressurized tank lined with polytetrafluoroethylene Still (volume filling degree is 70%), and placed in a constant temperature box at 100 ℃ constant temperature organic solvent-hydrothermal treatment for 12h, after taking it out, let it cool to room temperature naturally, filter the product obtained after the organic solvent-hydrothermal treatment, respectively Wash 3 times with deionized water and 3 times with absolute ethanol, dry at 60°C for 12h, rais...

Embodiment 2

[0017] Example 2: Under stirring conditions, to ethanol with a volume ratio of 5:5:1: ethylene glycol: concentrated HNO 3 (concentration is 67%) in the mixed solution (total volume is 55mL) add 30mmol dodecylamine, after waiting to mix uniformly, add 10mmol Bi(NO 3 ) 3 ·5H 2 O powder and 10 mmol NH 4 VO 3 Powder, adjust the pH of the solution to 3 with a volume ratio of 1:1 ethanol and ethylene glycol sodium hydroxide (2mol / L) alcohol solution, and transfer the above mixed solution to a 100mL stainless steel self-pressurized tank lined with polytetrafluoroethylene Still (the volume filling degree is about 70%), and placed in a constant temperature box at 100 ° C constant temperature organic solvent-hydrothermal treatment for 12 hours, after taking it out, let it cool to room temperature naturally, filter the product obtained after the organic solvent-hydrothermal treatment, Washed three times with deionized water and three times with absolute ethanol respectively, dried at...

Embodiment 3

[0018] Embodiment 3: Under stirring condition, to volume ratio is 5: 5: 1 ethanol: ethylene glycol: concentrated HNO 3 (concentration is 67%) in the mixed solution (total volume is 55mL) add 30mmol oleylamine, after mixing uniformly, add 10mmol Bi(NO 3 ) 3 ·5H 2 O powder and 10 mmol NH 4 VO 3 Powder, adjust the pH of the solution to 1.5 with ethanol and ethylene glycol sodium hydroxide (2mol / L) alcohol solution with a volume ratio of 1:1, and transfer the above mixed solution to a 100mL stainless steel self-pressurized tank lined with polytetrafluoroethylene Still (the volume filling degree is about 70%), and placed in a constant temperature box at 100 ° C constant temperature organic solvent-hydrothermal treatment for 12 hours, after taking it out, let it cool to room temperature naturally, filter the product obtained after the organic solvent-hydrothermal treatment, Washed three times with deionized water and three times with absolute ethanol respectively, dried at 60°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com