Mineral separation method for scheelite containing rich pyrrhotite

A technology of pyrrhotite and beneficiation method, which is applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problems of inability to guarantee the quality and recovery rate of tungsten concentrate, and achieves reduction of flotation beneficiation volume, Save recycling costs and improve the effect of selected grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

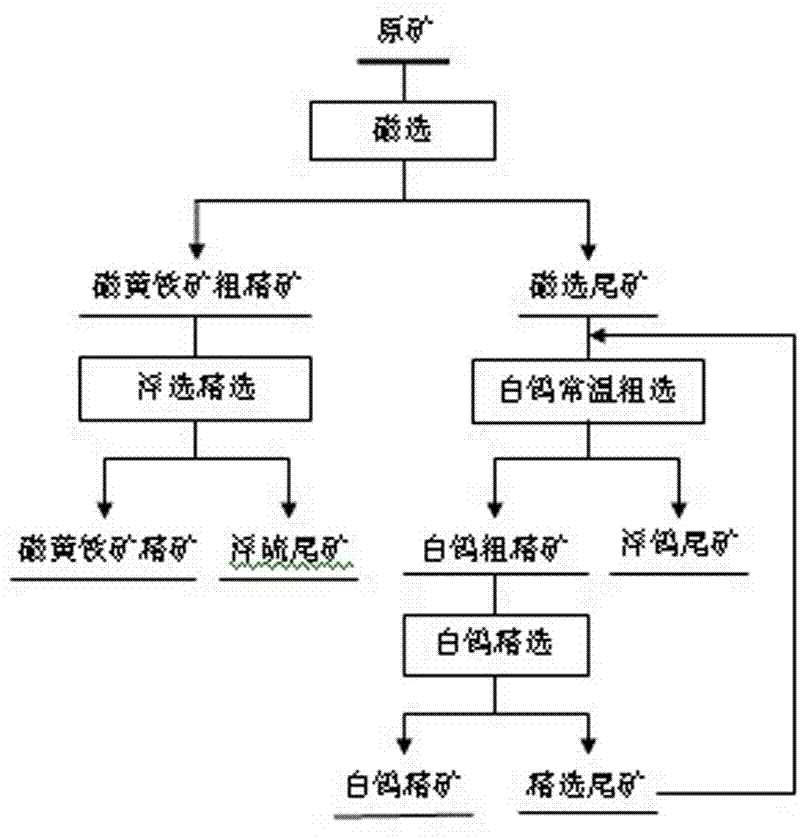

Method used

Image

Examples

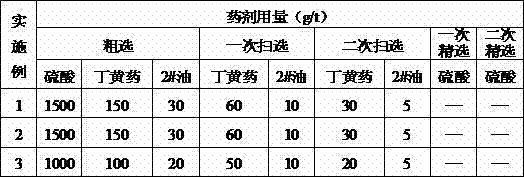

Embodiment 1

[0020] WO of a tungsten mine in Jiangxi 3 0.75% scheelite, magnetically separated under the magnetic induction intensity of 5000Gs; according to the amount of chemicals listed in Table 1, carry out pyrrhotite flotation and concentration on the magnetic separation concentrate, and obtain pyrrhotite concentrate with a sulfur content of more than 35.26% and floating sulfur tailings; carry out scheelite roughing at room temperature to the magnetic separation tailings according to the amount of chemicals listed in Table 2. Tailings: Concentrate coarse scheelite concentrate to 65% mass concentration, heat to 90°C, stir for 60 minutes, add reagents according to the amount shown in Table 2, and perform heating flotation to obtain scheelite concentrate. Scheelite Concentrate Grade WO 3 65.37%, recovery rate 89.49%, the results are shown in Table 3.

[0021] The result of table 3 embodiment 1

[0022]

Embodiment 2

[0024] WO of a tungsten mine in Jiangxi 3 0.72% scheelite, magnetically separated under the magnetic induction intensity of 5000Gs; perform pyrrhotite flotation and concentration on the magnetically separated concentrate according to the amount of reagents listed in Table 1, and obtain pyrrhotite concentrate with a sulfur content of more than 35.26% and floating sulfur tailings; carry out scheelite roughing at room temperature to the magnetic separation tailings according to the amount of chemicals listed in Table 2. Tailings: Concentrate coarse scheelite concentrate to a mass concentration of 65%, stir at room temperature for 60 minutes, add reagents according to the amount shown in Table 2 for flotation to obtain scheelite concentrate. Scheelite Concentrate Grade WO 3 51.46%, recovery rate 87.45%, the results are shown in Table 4.

[0025] The result of table 4 embodiment 2

[0026]

Embodiment 3

[0028] WO of a tungsten mine in Yunnan 3 0.55% scheelite, magnetically separated under the magnetic induction intensity of 6000Gs; according to the amount of chemicals listed in Table 1, carry out pyrrhotite flotation and concentration on the magnetic separation concentrate to obtain pyrrhotite concentrate with a sulfur content of more than 36.79% and floating sulfur tailings; carry out scheelite roughing at room temperature to the magnetic separation tailings according to the amount of chemicals listed in Table 2. Tailings: Concentrate coarse scheelite concentrate to 60% mass concentration, heat to 90°C, stir for 90 minutes, add reagents according to the amount shown in Table 2, and perform heating flotation to obtain scheelite concentrate. Scheelite Concentrate Grade WO 3 66.28%, recovery rate 87.29%, the results are shown in Table 5.

[0029] The result of table 5 embodiment 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com