Beneficiation reagent and method for separating scheelite from complex tungsten ore

A mineral dressing agent and tungsten ore technology, applied in solid separation, flotation, etc., can solve the problems of high cost of mineral processing, heating ore pulp, etc., and achieve the effect of low cost, easy operation, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

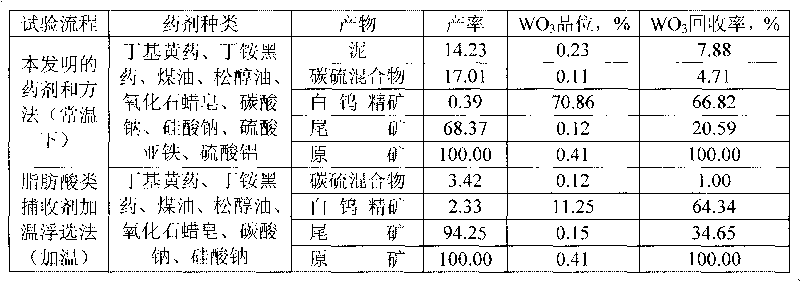

[0033] A beneficiation agent for separating scheelite from complex tungsten ores, the beneficiation agent includes oxidized paraffin wax soap 8, kerosene 1, butyl xanthate 2, butylammonium black medicine 3 as collectors, and sodium carbonate 5 as regulator , using terpineol oil 4 as a foaming agent, and using a combination of sodium silicate 6 and ferrous sulfate 7 or aluminum sulfate 9 as an inhibitor.

[0034] The mineral processing agent for separating scheelite from complex tungsten ores, the mineral processing agent is to add 470-1350 grams of oxidized paraffin soap 8, 30-150 grams of kerosene 1, and 150-550 grams of butyl xanthate per ton of raw ore 2. Add 30-150 grams of butyl ammonium black medicine 3. Add 2000-4500 grams of sodium carbonate 5. Add 10-60 grams of pinitol oil 4. Add 3050-7000 grams of sodium silicate 6 and add 400-1300 grams of ferrous sulfate 7 or add 65 to 160 grams of aluminum sulfate 9.

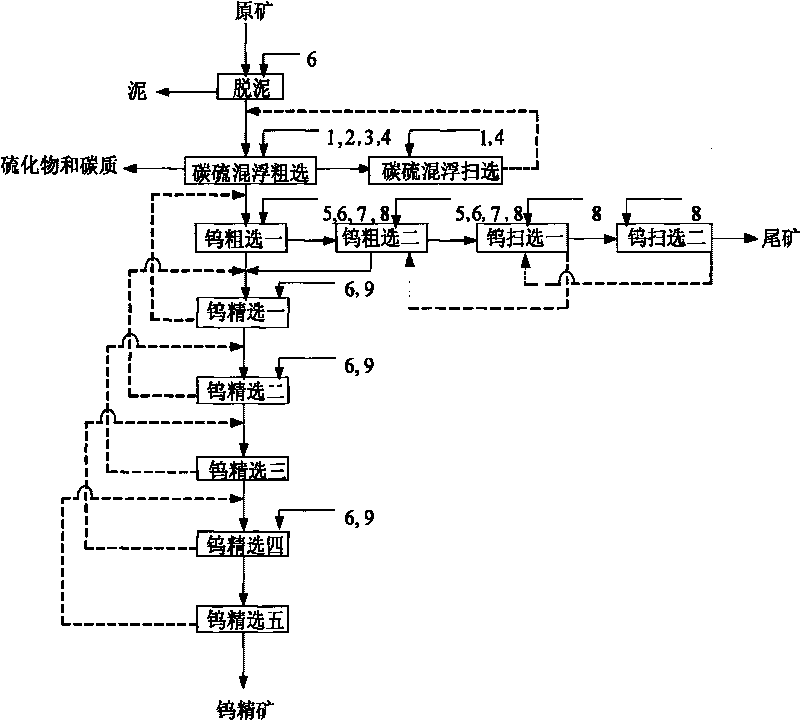

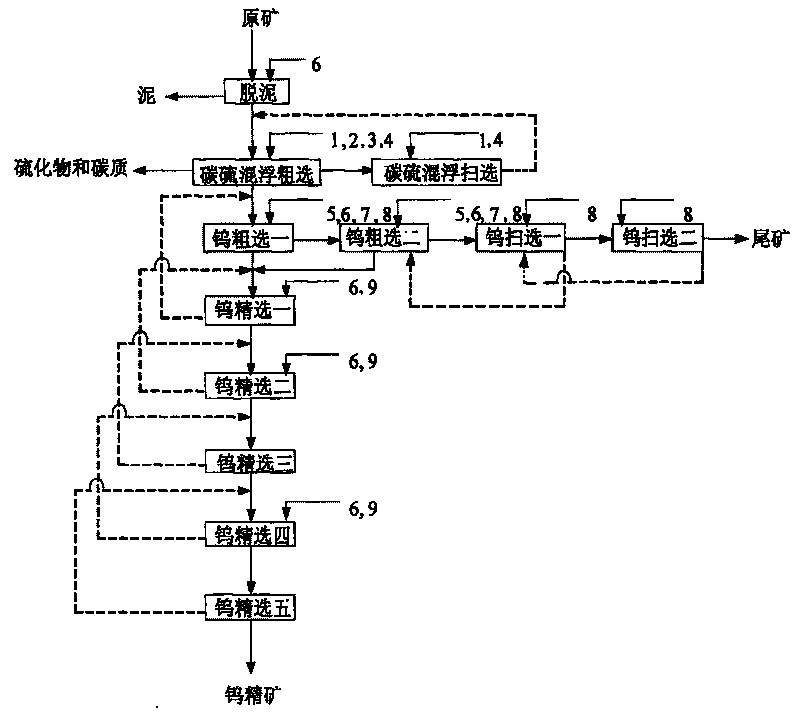

[0035] Such as figure 1 As shown, a method for separating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com