Method for decomposing scheelite with ammonium salts

A technology of scheelite and ammonium salt, which is applied in the direction of improving process efficiency to achieve the effect of reducing auxiliary reagents and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Raw materials and reagents: scheelite WO 3 Content 67%, industrial ammonium phosphate (NH 4 ) 3 PO 4 ·3H 2 O content 98%, industrial liquid ammonia content 99%.

[0021] Decomposition device: 1L far-infrared heating stainless steel autoclave.

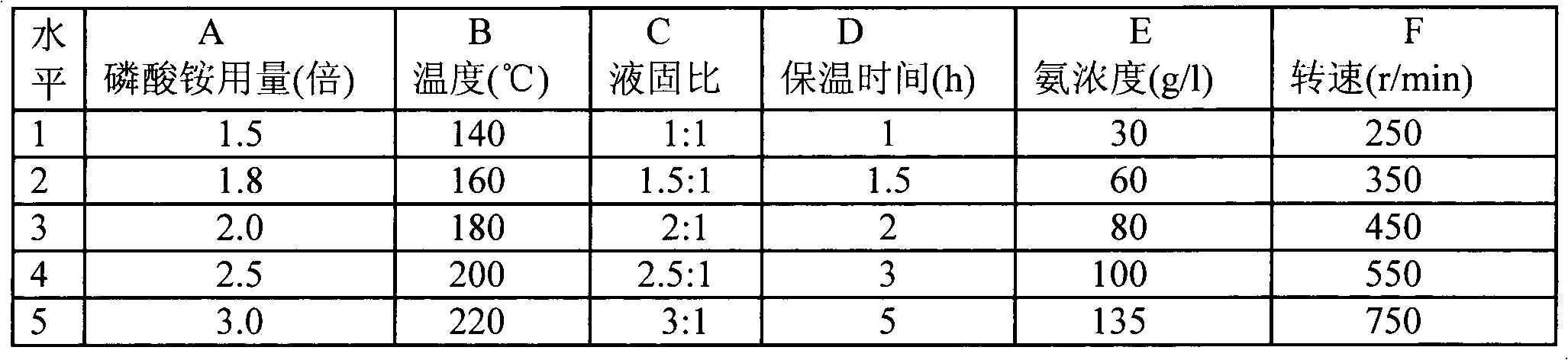

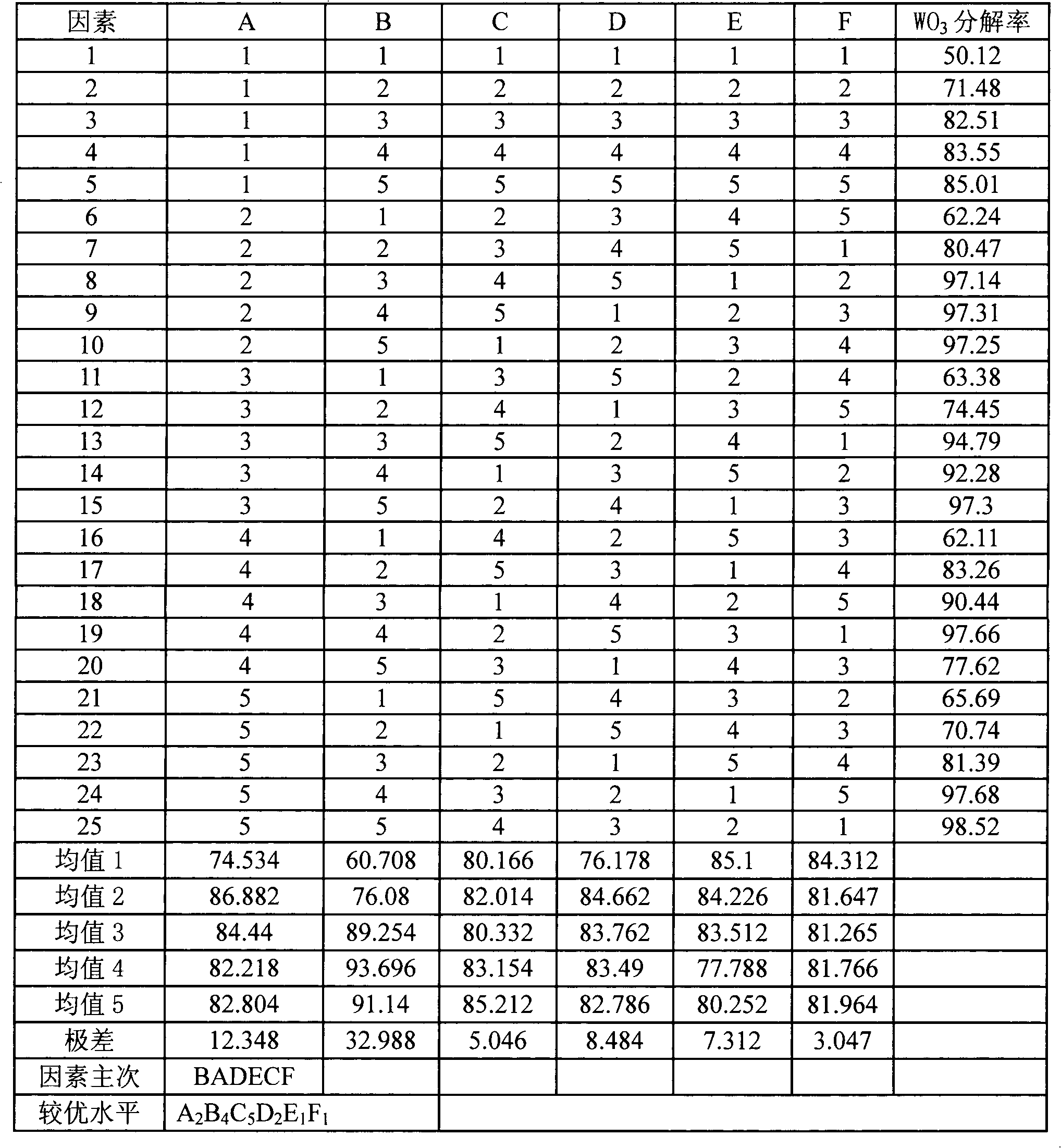

[0022] Results: The levels of each influencing factor were determined according to the results of the single factor experiment, and the orthogonal table was established by selecting six factors including the amount of ammonium phosphate, temperature, holding time, liquid-solid ratio, ammonia concentration, and stirring speed. The experiment is still carried out in a 1L autoclave, and the amount of scheelite used in each experiment is 100g. The amount of ammonium phosphate is 1.5, 1.8, 2.0, 2.5, 3.0 times of the theoretical amount; the reaction temperature (°C) is: 140, 160, 180, 200, 220; , 5; the ammonia concentration (g / l) is 30, 60, 80, 100, 135; the liquid-solid ratio is: 1, 1.5, 2, 2.5, 3; the stirring speed (r / min) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com