A gallium nitride-based semiconductor light-emitting tube with a p-type active region

A gallium nitride-based, active region technology, applied in the field of gallium nitride-based semiconductor light-emitting tubes, can solve problems such as uneven carrier distribution, low minority carrier injection efficiency, and limited number of quantum wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

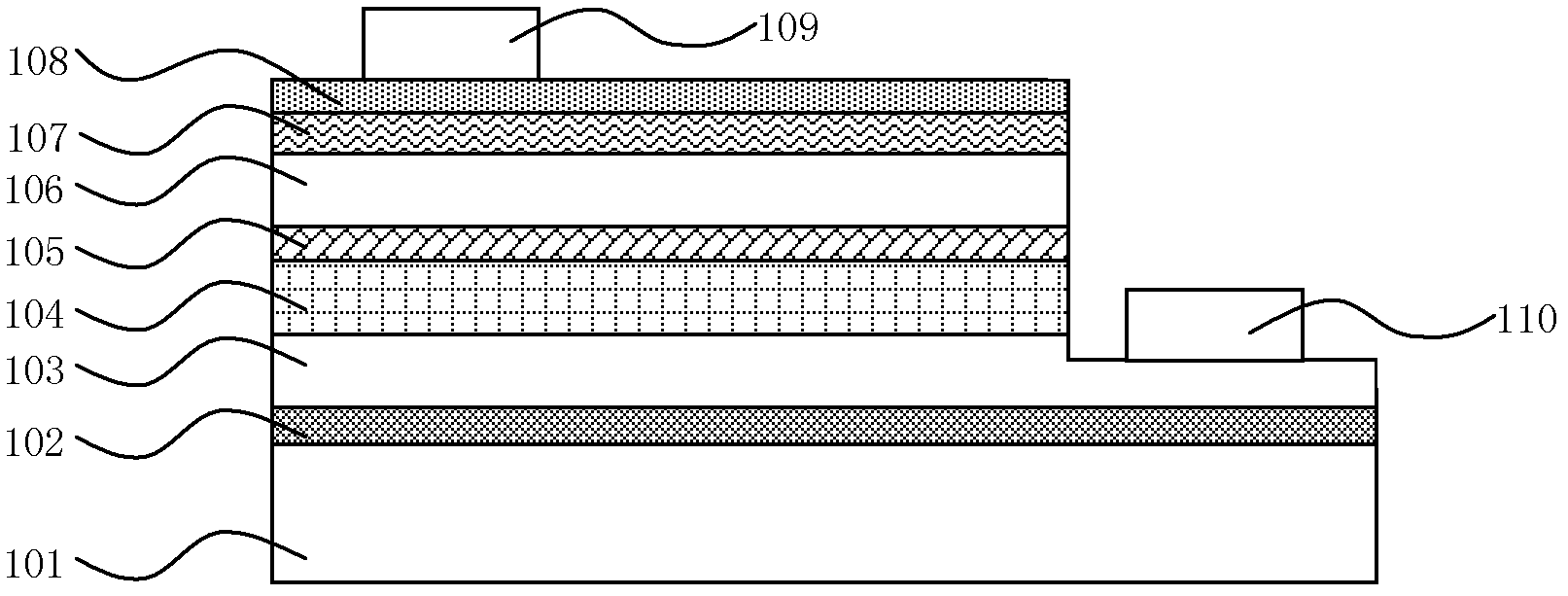

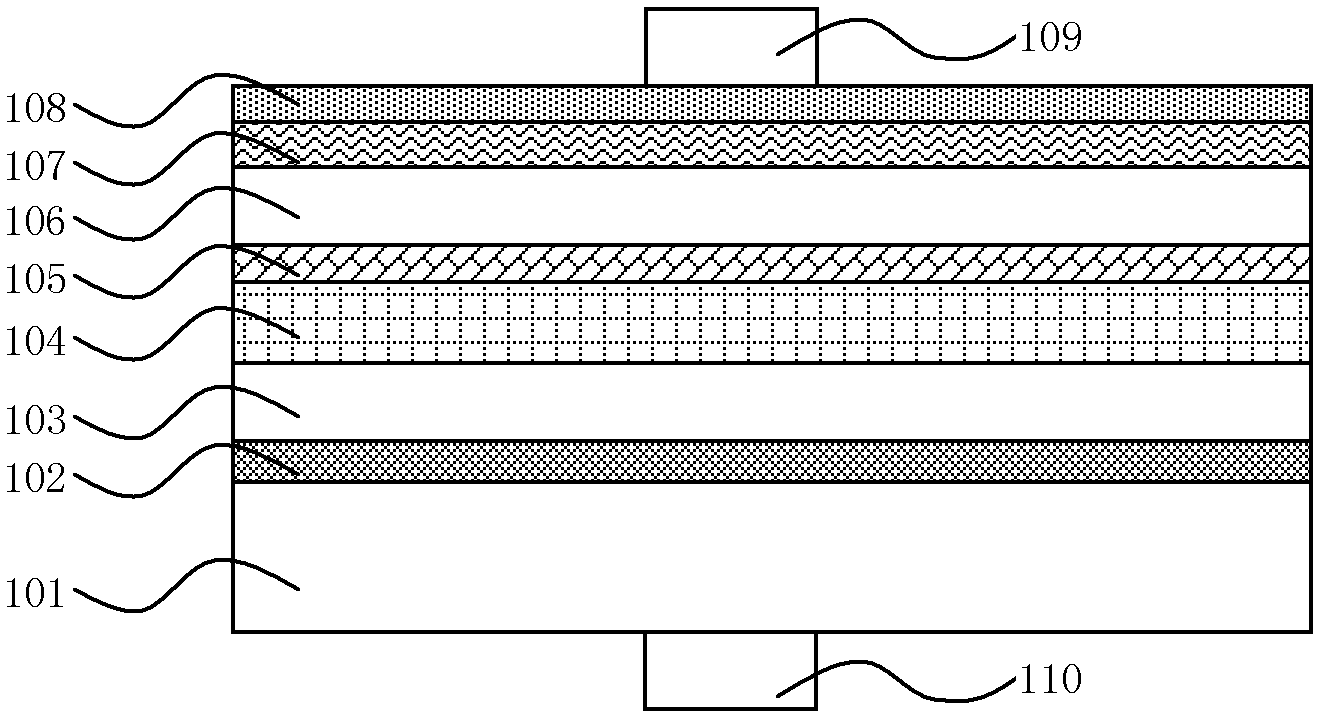

Embodiment 1

[0027] Place the sapphire substrate (101) in the MOCVD reaction chamber, first raise the temperature of the reaction chamber to 600-1100°C, preferably at 1100°C, and bake the substrate in a hydrogen atmosphere to remove surface impurities. In the range of 600~1100℃, use NH 3 or NH 3 with H 2 The mixed gas is used to treat the substrate surface.

[0028] The temperature of the reaction chamber is lowered to within the range of 550-560° C., preferably 560° C., and the Ga source and the N source are supplied to grow a buffer layer (102) with a thickness of 20-30 nm.

[0029] The temperature of the reaction chamber is raised to 1040-1080°C, and the Ga source and N source are introduced to grow a 2 μm thick non-doped GaN material, and then the reaction chamber is added with a Si source to grow a 2 μm thick N-type doped GaN material ( 103).

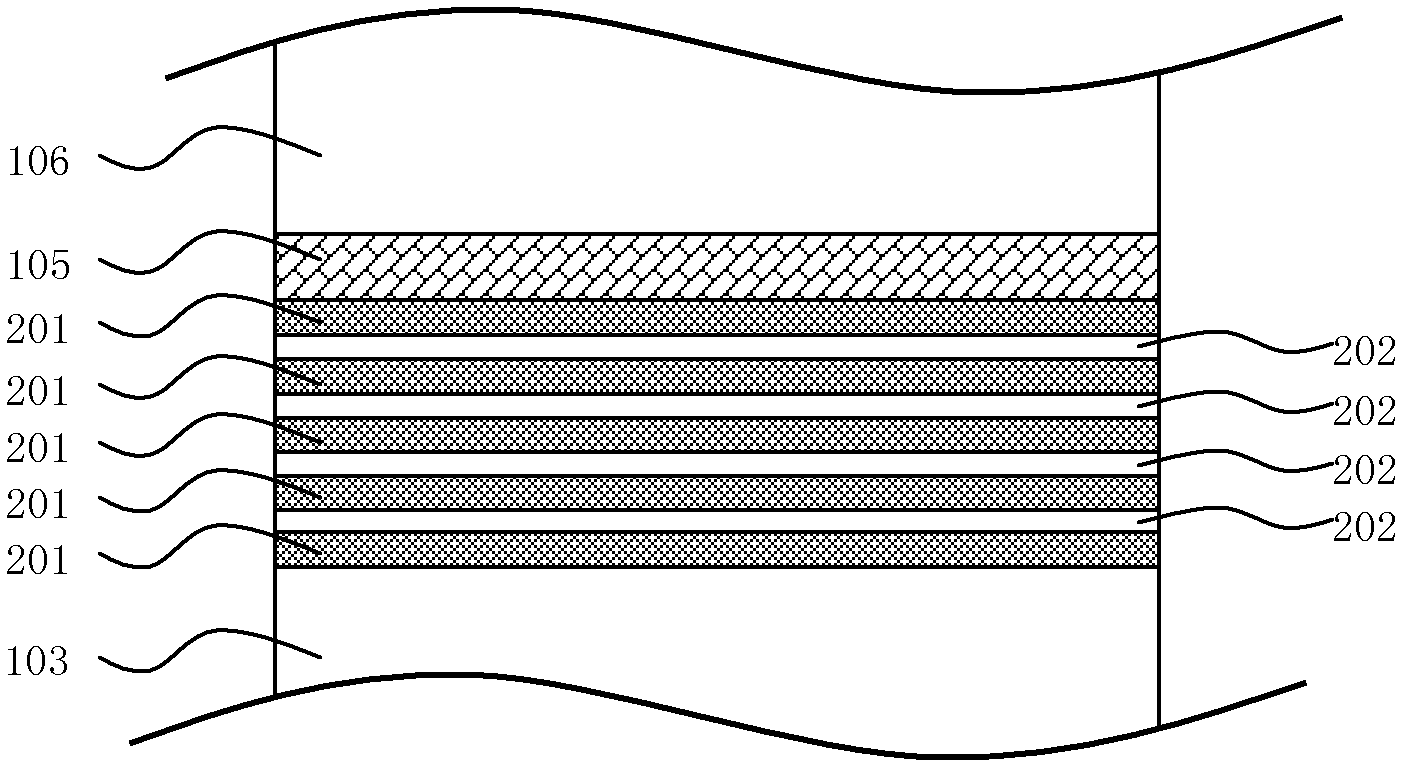

[0030] Cool the reaction chamber to 650-900°C, preferably 700-850°C, and grow 4 cycles of In x Ga 1-x N(202, 0x Ga 1-x N as a potential...

Embodiment 2

[0038] The specific implementation method of Embodiment 2, except that the structure of the active region is different from that of Embodiment 1, other parts can use the same process steps, which will not be repeated here. The following only introduces the manufacturing process of its active region structure.

[0039] After the growth of the N-type GaN material (103) is completed, the temperature of the reaction chamber is lowered to within the range of 650-900° C., preferably 700-850° C., and four cycles of In x Ga 1-x N(202) / GaN(201) multiple quantum well structure (104, active region). Specifically, the reaction chamber is fed with Ga source and N source to grow the GaN barrier layer, the thickness of the barrier layer is in the range of 2-50nm, preferably 3-20nm, and the Mg source is used as a P-type dopant during the growth process of the GaN barrier layer. Growth potential well layer In x Ga 1-x Ga source, N source, and In source are connected to the reaction chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com