Solid-state imaging device and method for producing the same

a solid-state imaging and imaging device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical devices, etc., can solve the problems of affecting the quality of solid-state imaging, so as to reduce the distance, suppress the extension of the diffusion length of an impurity in the device region, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

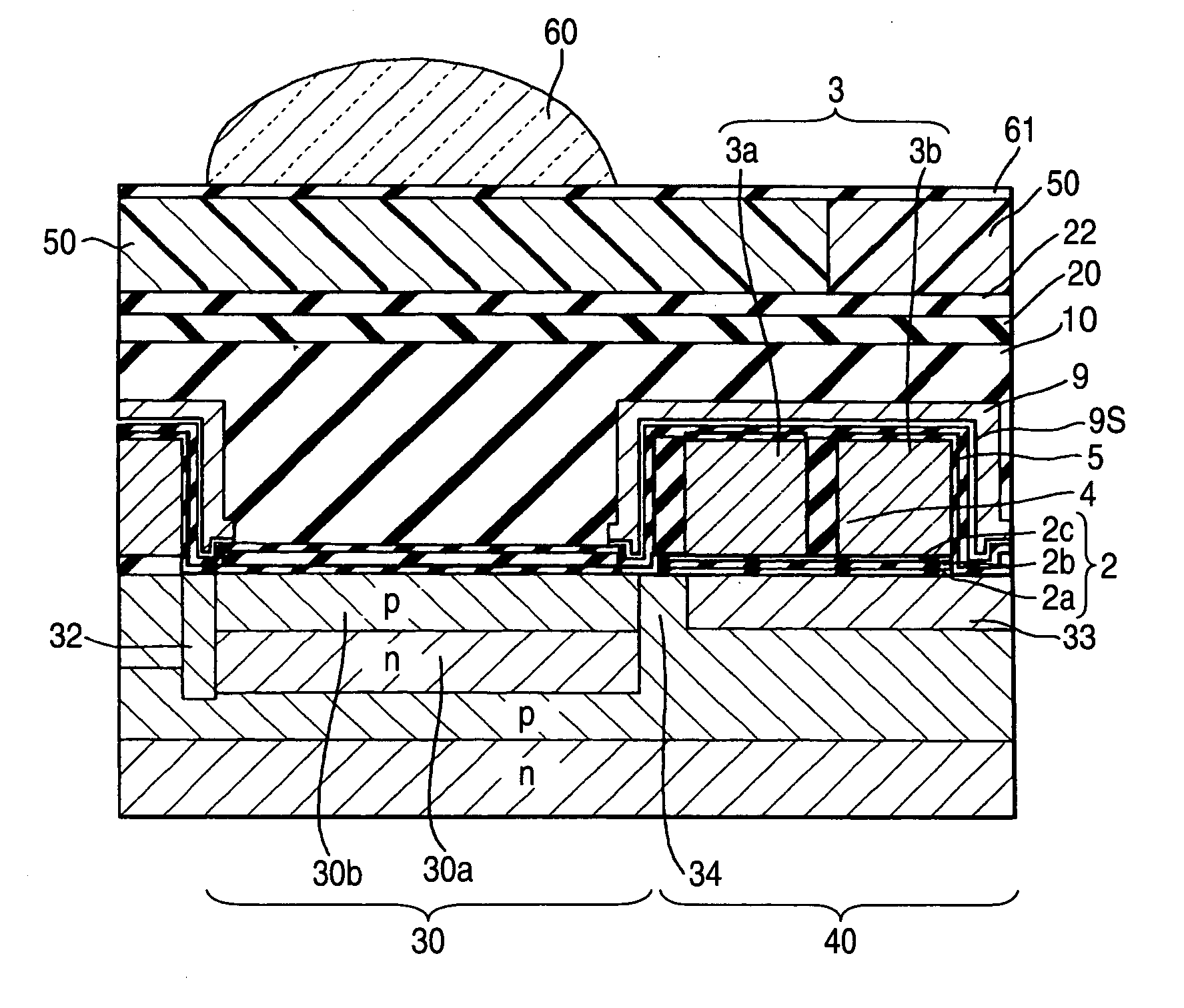

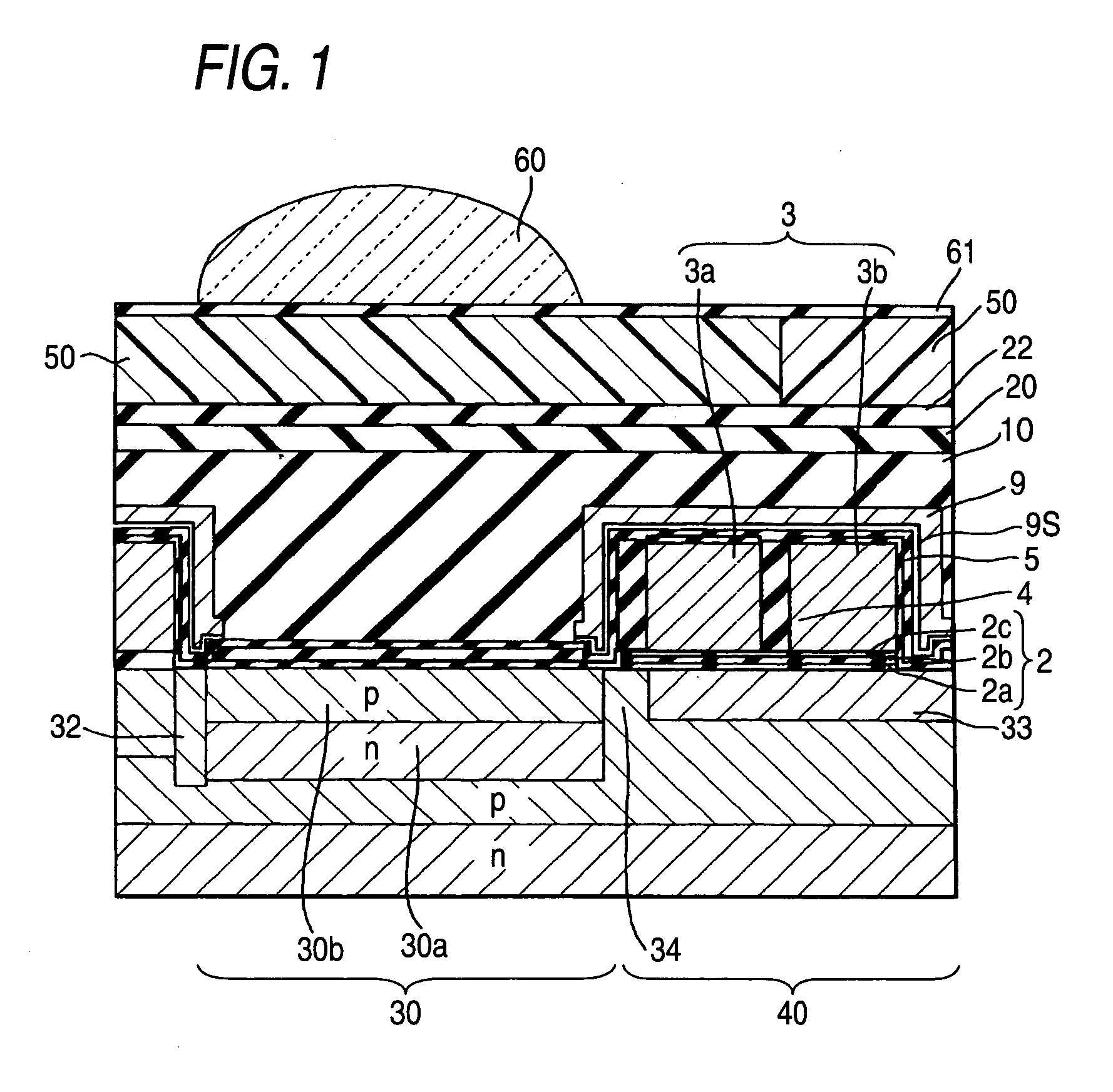

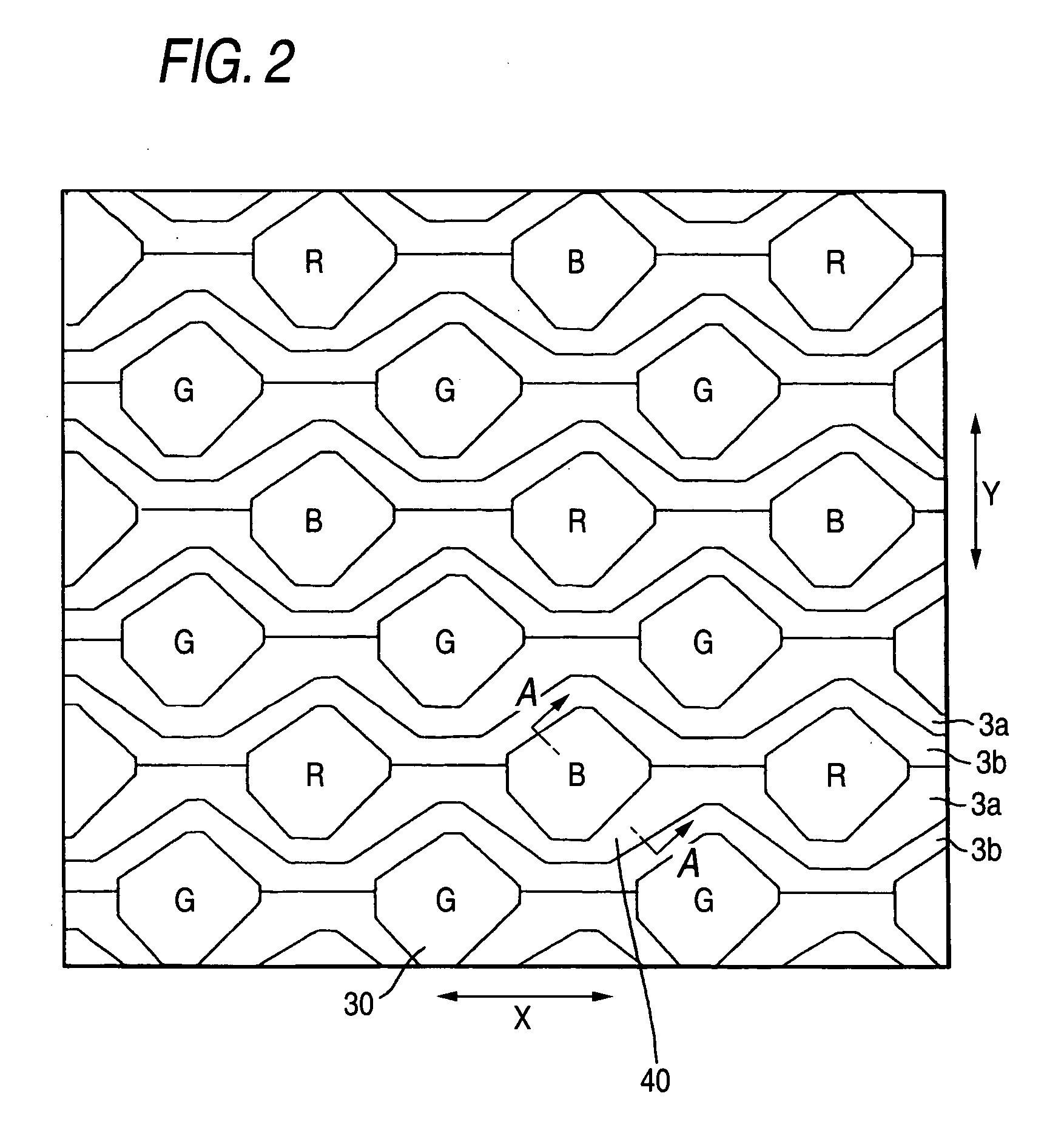

[0048] This solid-state imaging device has, as shown in FIGS. 1 and 2, a photoelectric conversion section, a charge transfer section equipped with a charge transfer electrode for transferring an electric charge generated in the photoelectric conversion section, and an antireflection film 7 formed in the photoelectric conversion section, wherein a light-shielding film covering the charge transfer electrode is formed to reach a level lower than the top surface of the antireflection film 7 and surround the periphery of the antireflection film. By virtue of this constitution, a high-precision high-sensitivity solid-state imaging device capable of blocking intrusion of light into the charge transfer section due to multiple reflection can be provided. Here, the antireflection film is composed of a silicon nitride film, and its top and bottom layers are covered with an insulating film comprising a silicon oxide film using a low-temperature plasma. FIG. 1 is a cross-sectional schematic view...

embodiment 2

[0078] In Embodiment 1, on the photoelectric conversion section, the gate oxide film 2 is completely removed and a silicon oxide film 5 is formed by radical oxidation to cover the entire surface, but when the gate oxide film 2 is composed of an oxide nitride oxide (ONO) film, the antireflection film may be formed thereon.

embodiment 3

[0079] In Embodiment 1, the silicon oxide films 5 and 8 are formed by radical oxidation to sandwich the antireflection film and thereby cover the entire surface of the antireflection film, but if slight reduction in the passivation property is allowed, either one of those silicon oxide films may be omitted.

[0080] Also, the light-shielding metal is not limited to tungsten and may be appropriately changed to titanium (Ti), cobalt (Co), nickel (Ni) or the like.

[0081] Incidentally, the production method is not limited to the above-described Embodiments but may be appropriately changed.

[0082] As described in the foregoing pages, according to the present invention, an island-like antireflection film can be easily and self-alignedly formed on a photodiode with good controllability and this enables elevation of sensitivity and reduction of smears. Therefore, the present invention is effective for the fabrication of a fine and high-sensitivity solid-state imaging device such as compact ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com