Copper-zinc-tin-sulfide-selenium film and preparation method thereof as well as copper-zinc-tin-sulfide-selenium film solar cell

A copper-zinc-tin-sulfur-selenium and thin-film technology, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of low collection efficiency, short lifespan of photogenerated carriers, and low photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

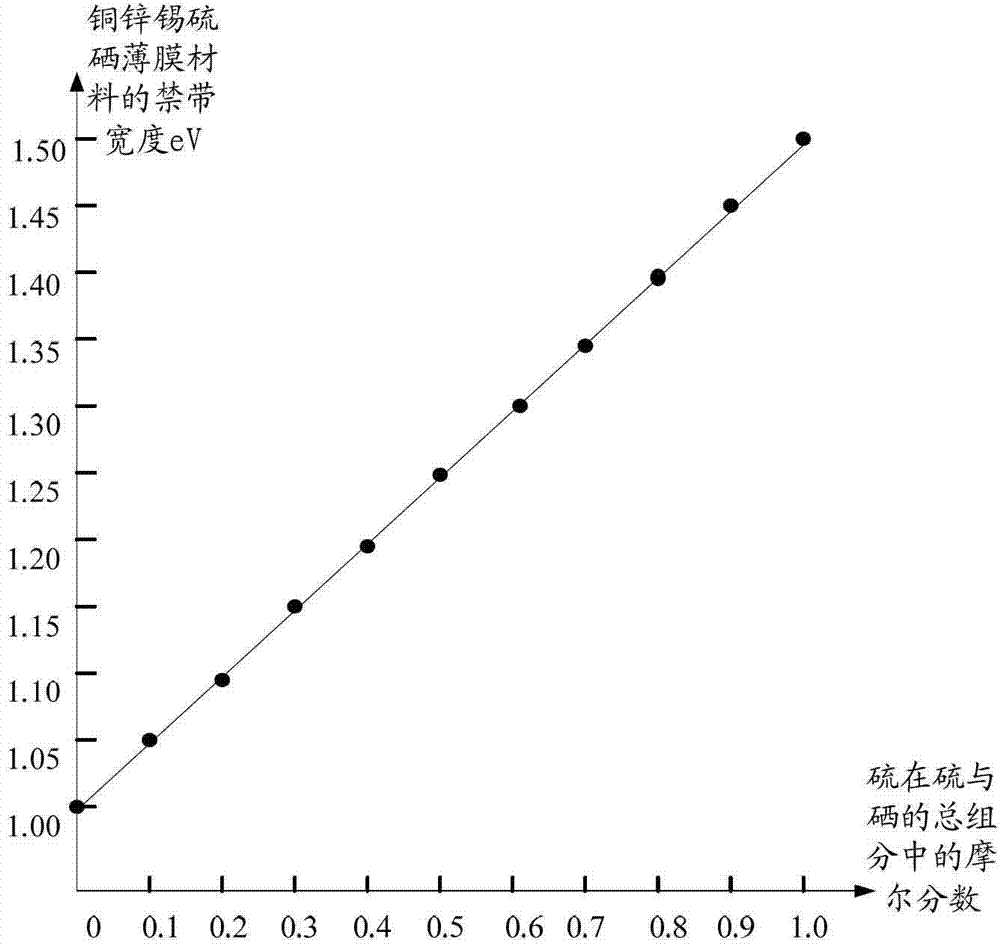

[0039] In order to solve the problem that the diffusion length of carriers in copper-zinc-tin-sulfur-selenide materials is too small, and the charges generated deep in the material cannot be effectively collected, resulting in low photoelectric conversion efficiency, a copper-zinc material with high photoelectric conversion efficiency was proposed. Tin-sulfur-selenium thin film and copper-zinc-tin-sulfur-selenium thin-film solar cell.

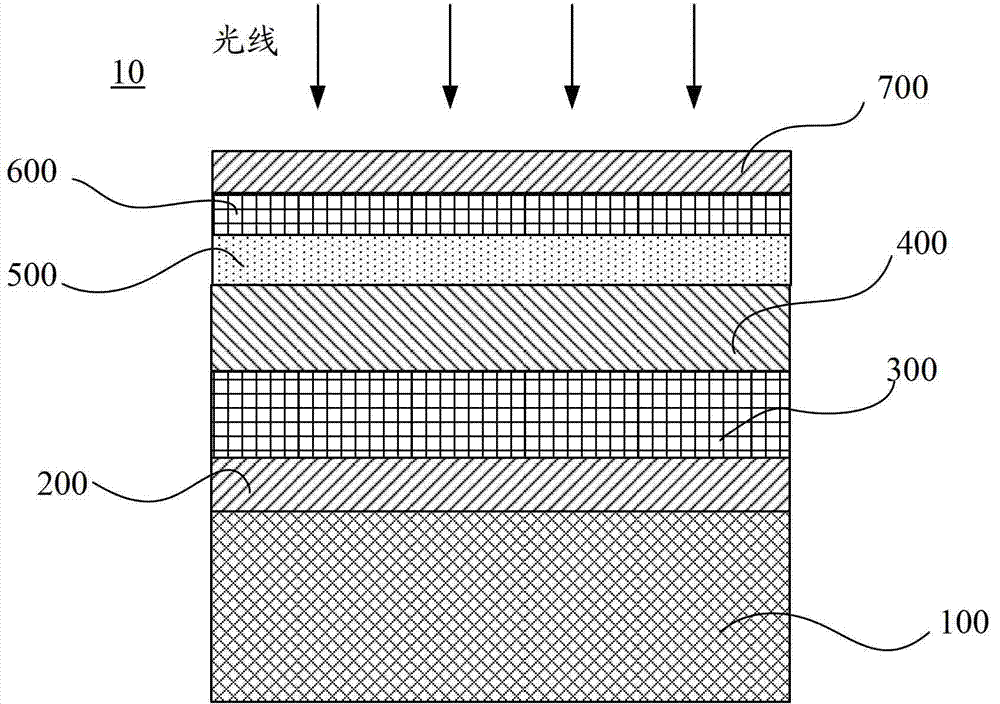

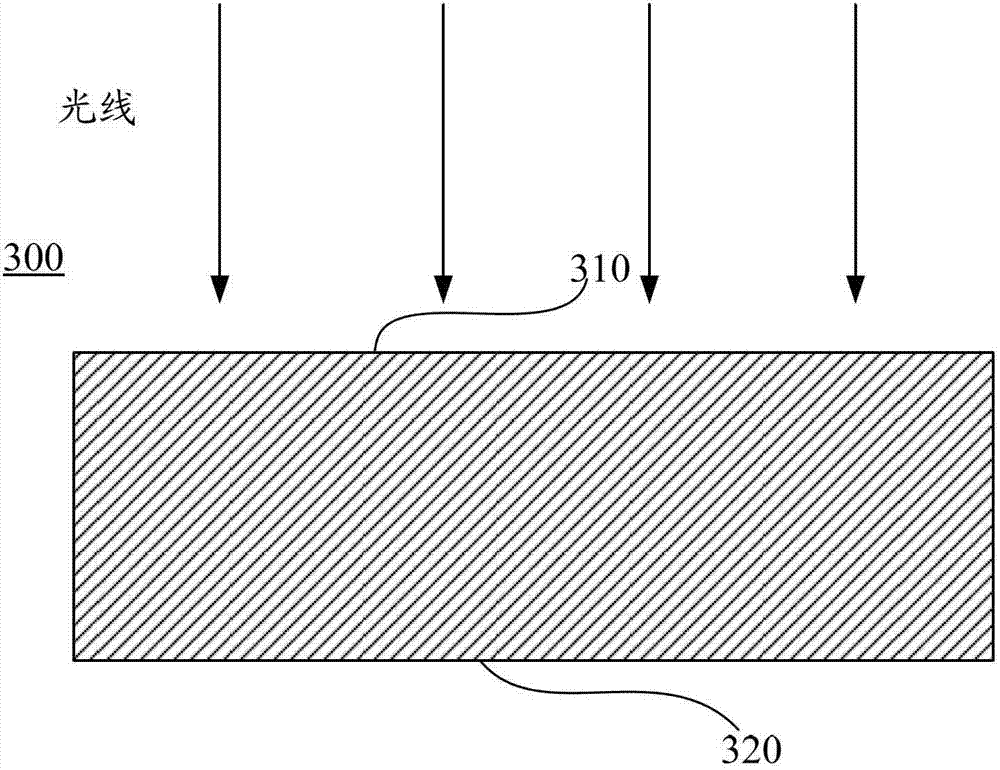

[0040] see figure 1 , the copper zinc tin sulfur selenium thin film solar cell 10 of this embodiment includes a substrate 100 , a back electrode layer 200 , a light absorbing layer 300 , a buffer layer 400 , a window layer 500 , a transparent electrode layer 600 and a metal gate layer 700 . Wherein, the light absorbing layer 300 is a copper zinc tin sulfur selenide thin film. When light energy is converted into electric energy, the light is transmitted from the buffer layer 400 and enters the copper zinc tin sulfur selenide film 300, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com