High-strength composite core, preparation method thereof and application of high-strength composite core in baby diapers

A high-strength, composite core technology, applied in applications, baby underwear, medical science, etc., can solve the problems of large usage, poor aging resistance, discomfort, etc., achieve high fiber cross-sectional diameter, strong aging resistance, and non-toxic easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

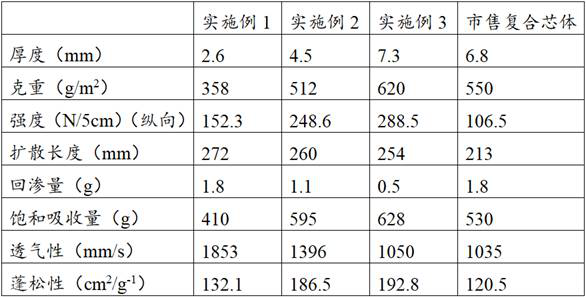

Examples

preparation example Construction

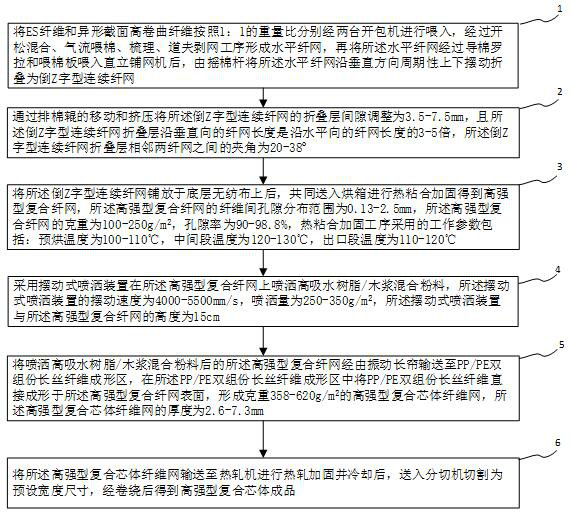

[0037] figure 1 It is a method flowchart of a method for preparing a high-strength composite core shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of this high-strength type composite core comprises:

[0038] Step (1): Feed the ES fiber and high-crimp fiber with special-shaped cross-section through two bale opening machines respectively according to the weight ratio of 1:1, and form a horizontal fiber web through the processes of opening and mixing, air-flow feeding, carding, and doffer stripping , and then the horizontal fiber web is fed into the vertical web lapper through the cotton guide roller and the cotton feeding plate, and the horizontal fiber web is periodically oscillated up and down in the vertical direction by the rocking cotton rod and folded into an inverted Z-shaped continuous fiber web .

[0039] Optionally, the ES fiber is a hydrophilic PE / PP fiber, the fiber fineness of the ES fiber is 8-10D, the length is 50-52mm,...

Embodiment 1

[0057]Step (1): Feed the ES fiber and high-crimp fiber with special-shaped cross-section through two bale opening machines respectively according to the weight ratio of 1:1, and form a horizontal fiber web through the processes of opening and mixing, air-flow feeding, carding, and doffer stripping , and then the horizontal fiber web is fed into the vertical web lapper through the cotton guide roller and the cotton feeding plate, and the horizontal fiber web is periodically oscillated up and down in the vertical direction by the rocking cotton rod and folded into an inverted Z-shaped continuous fiber web .

[0058] The ES fiber is a hydrophilic PE / PP fiber, the fiber fineness of the ES fiber is 8D, the length is 50mm, and the number of crimps is 580 / m.

[0059] The highly crimped fiber with special-shaped cross-section is a hydrophilic PTT fiber with C-shaped cross-section. The fiber fineness of the highly crimped fiber with special-shaped cross-section is 20D, the length is 64...

Embodiment 2

[0074] Step (1): Feed ES fiber and highly crimped fiber with special-shaped cross-section through two bale opening machines respectively according to the weight ratio of 40:60, and form a horizontal fiber web through the processes of opening and mixing, air-flow feeding, carding, and doffer stripping , and then the horizontal fiber web is fed into the vertical web lapper through the cotton guide roller and the cotton feeding plate, and the horizontal fiber web is periodically oscillated up and down in the vertical direction by the rocking cotton rod and folded into an inverted Z-shaped continuous fiber web .

[0075] The ES fiber is a hydrophilic PE / PP fiber, the fiber fineness of the ES fiber is 9D, the length is 51mm, and the number of crimps is 590 / m.

[0076] The highly crimped fiber with a special-shaped cross section is a hydrophilic PTT fiber with a C-shaped cross-section. The fiber fineness of the highly crimped fiber with a special-shaped cross-section is 20D, the len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com