Chemical vapor deposition preparation method for perovskite solar cell

A technology of chemical vapor deposition and solar cells, which is applied to electrical components, gaseous chemical plating, circuits, etc., can solve the problems of expensive equipment, complicated process, porous, etc., and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

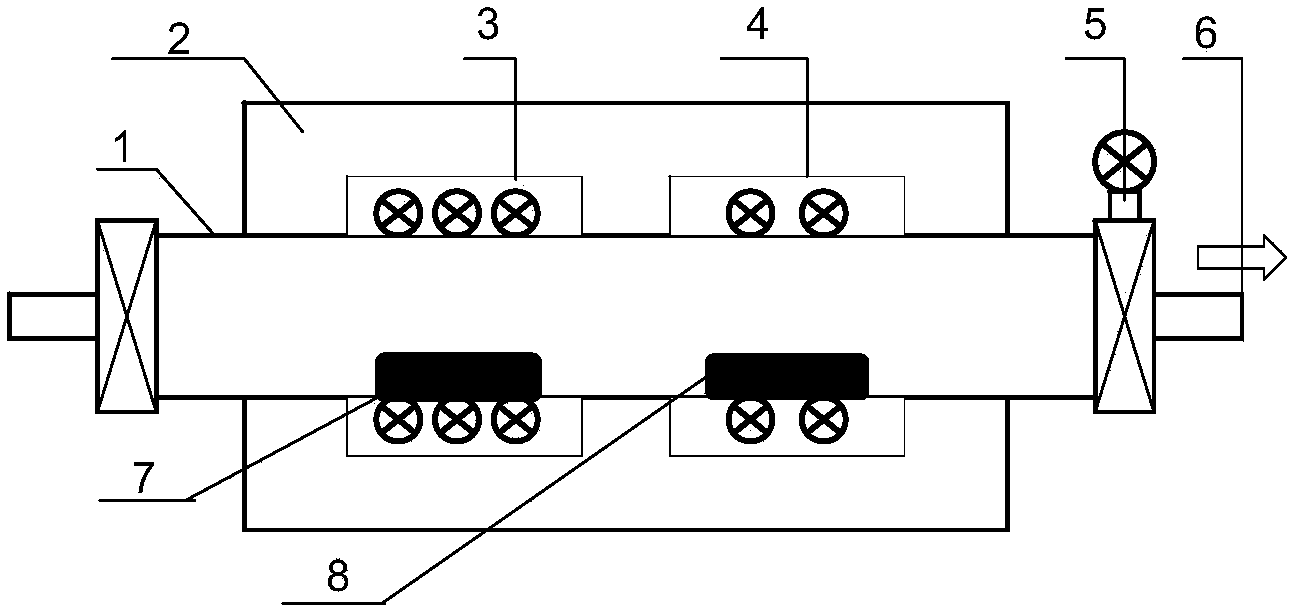

Method used

Image

Examples

Embodiment 1

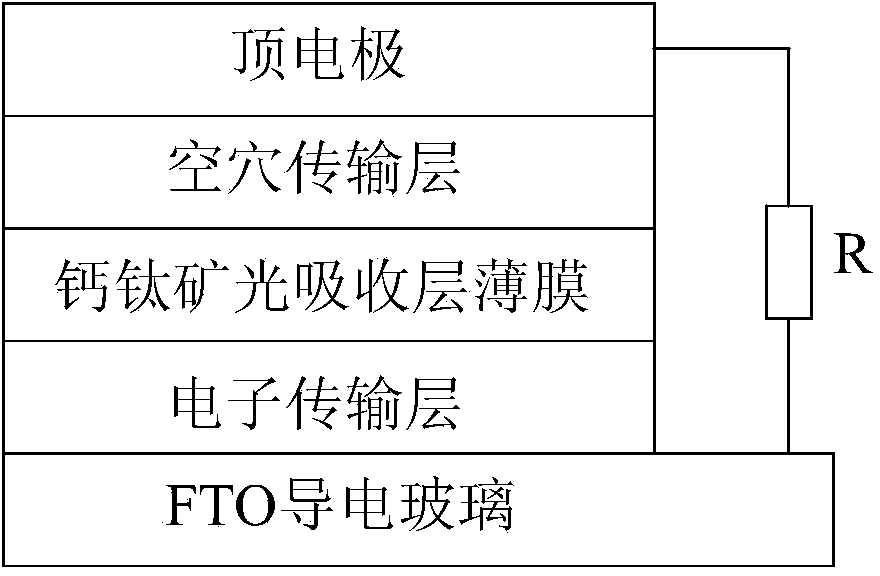

[0046] The structure diagram of the perovskite solar cell of the present embodiment is as follows figure 1 As shown, the FTO conductive glass is used as the substrate, and the electron transport layer, the perovskite light absorbing layer film, the hole transport layer and the top electrode are sequentially deposited on the surface of the FTO film of the FTO conductive glass from bottom to top. The specific preparation method for:

[0047] a. Deposit a dense layer of TiO on the surface of the FTO film of the FTO conductive glass 2 The thin film is used as the electron transport layer: Spin-coat 50 μL of isopropyl titanate ethanol solution with a concentration of 0.24mol / L on the surface of the FTO thin film of the FTO conductive glass at a speed of 2000rpm / 30s, and then sinter at 450°C for 30min in air. Then soak in 40mM TiCl 4 In an aqueous solution, treat at 70°C for 30 minutes, and finally sinter at 450°C for 30 minutes to obtain a dense layer of TiO with a thickness of 1...

Embodiment 2

[0058] In this example, a perovskite solar cell is prepared in the same manner as Example 1, with the difference that:

[0059] 1. Step a uses the following method to prepare a dense layer of TiO 2 film:

[0060] 0.5ml TiCl 4 Add dropwise to 2ml of absolute ethanol, then add 10ml of benzyl alcohol to obtain a yellow solution; react the yellow solution in a water bath at 80°C for 8 hours to obtain a milky white solution, add ether to the milky white solution to extract TiO to be cleaned 2 Precipitated, washed with ethanol and ether in turn to clean the TiO 2 Precipitate 3 times, then centrifuge out TiO 2 precipitation;

[0061] TiO 2 The precipitate was dispersed in ethanol to obtain a concentration of 8 mg / ml TiO 2 ethanol dispersion, then in 10ml TiO 2 Add 0.2ml of bis(acetylacetonato) diisopropyl titanate (TiAcac) in the ethanol dispersion liquid as stabilizer, obtain TiO 2 spin coating solution;

[0062] Drop 50 μL TiO on the surface of the FTO film of the FTO cond...

Embodiment 3

[0066] In this embodiment, a perovskite solar cell is prepared in the same manner as in Example 2:

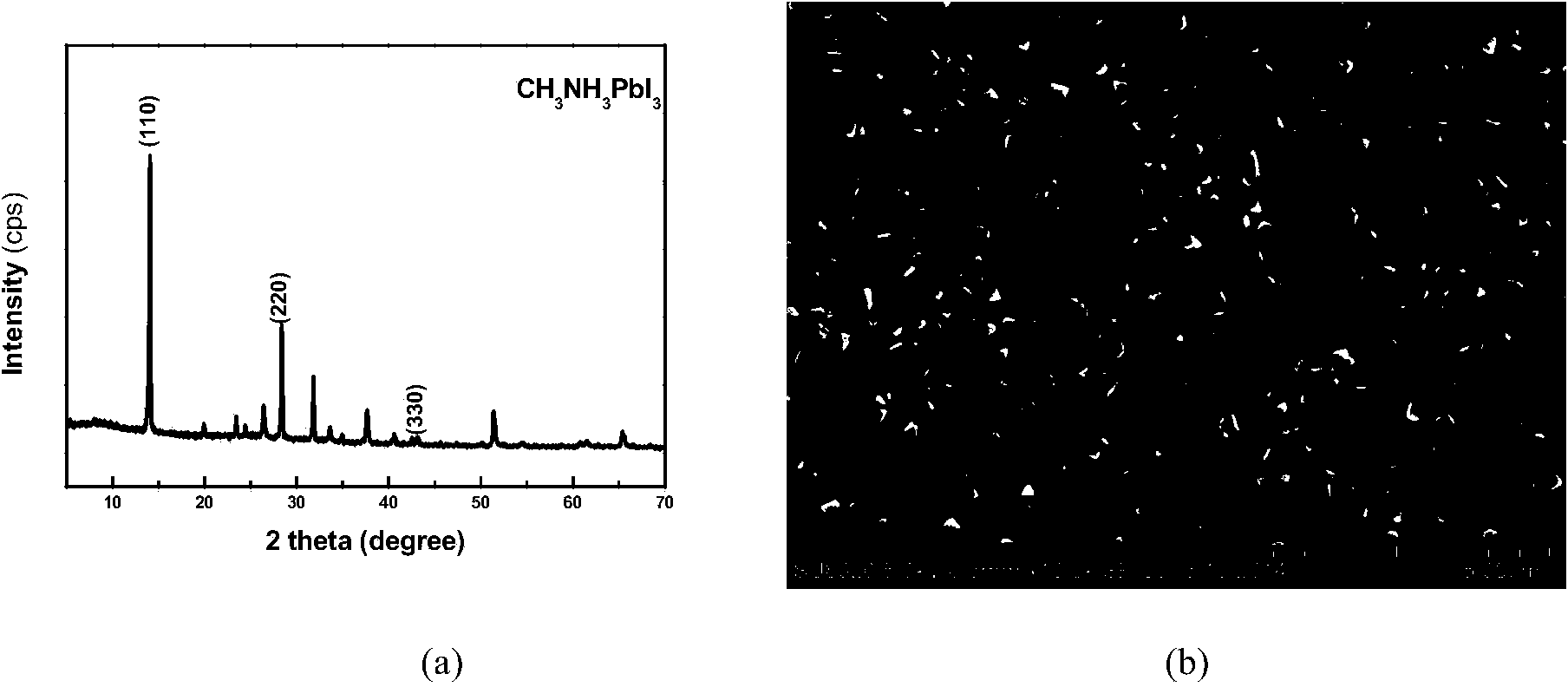

[0067] The difference is: in step b3, the position of the gas phase source is heated to 250°C, the position of the reactant is heated to 200°C, and the reaction is carried out for 80 minutes to obtain CH as a perovskite light-absorbing layer film. 3 NH 3 PB 3 film;

[0068] The calculated conversion efficiency of the perovskite solar cell obtained in this embodiment is 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com