Composite absorption core body provided with imbibition self-expanding type liquid guiding channel and application thereof

A technology of absorbing core and channel, applied in the application, absorbing pad, manufacturing tools and other directions, can solve the problems of large amount of re-osmosis, swelling and hardening, user wear and so on, and achieves good dryness, fast liquid infiltration speed, The effect of no swelling and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

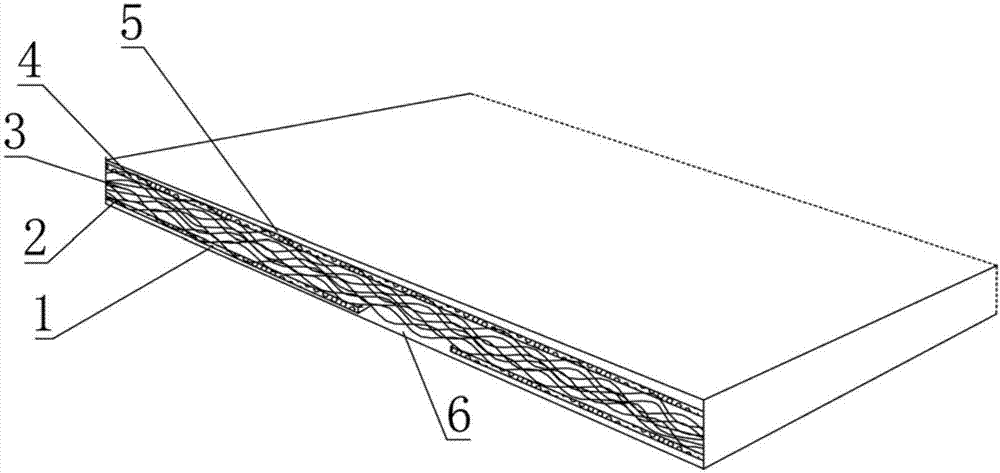

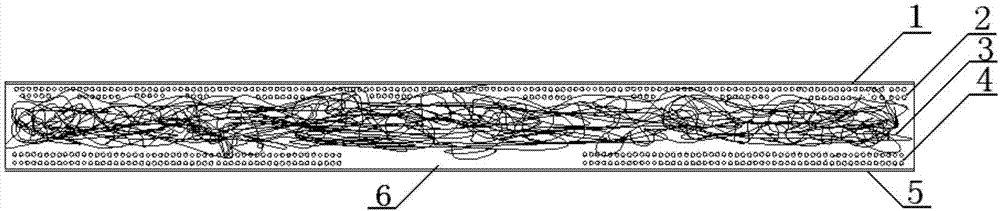

[0066] The preparation method of the composite absorbent core of the present invention may, for example, comprise the following steps:

[0067] (1) Place a baffle at the middle of the width of the bottom layer on the upper side of the bottom layer along its length, and then spray the hot-melt structural adhesive layer with a glue sprayer;

[0068] (2) Sprinkle the liquid-absorbing swelling material for forming the lower water-absorbing layer on the upper side of the bottom layer sprayed with hot-melt structural adhesive, and then lay the middle absorbing layer on the upper part of the lower water-absorbing layer;

[0069] (3) On the lower side of the surface layer, spray the hot-melt structural adhesive layer with a glue sprayer and sprinkle the liquid-absorbing expansive material for forming the upper water-absorbing layer;

[0070] (4) covering the material obtained in step (3) on the middle absorbent layer of the material obtained in step (2) in such a way that the side of ...

Embodiment 1

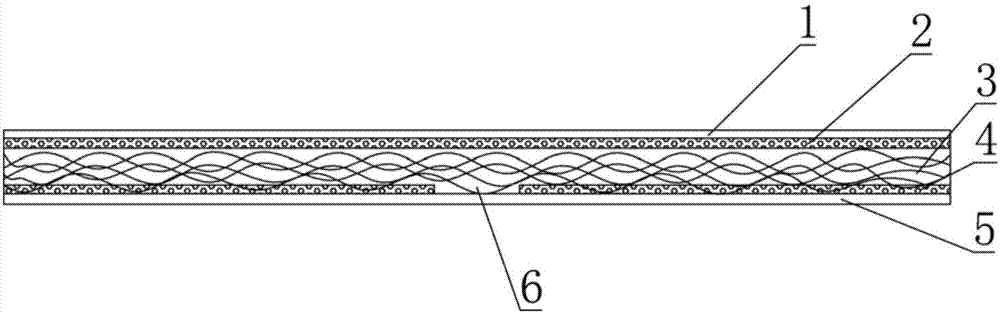

[0092] The surface layer adopts a width of 9cm and a weight of 10g / m 2 dust-free paper, the upper absorbent layer adopts a weight of 140g / m 2, 20-mesh polymer water-absorbing resin, the middle absorbent layer adopts a weight of 35g / m 2 The hot air fluffy non-woven fabric, the lower absorbent layer adopts a weight of 140g / m 2 , 40-mesh polymer water-absorbing resin, the bottom layer is 9cm in width and 10g / m in weight 2 dust-free paper; the preparation steps are:

[0093] 1) Place a 1cm wide strip baffle on the upper side of the bottom layer in the middle of the bottom layer width along its length, and then spray 0.5g / m2 with a glue sprayer 2 Hot-melt structural adhesive layer;

[0094] 2) Sprinkle the upper and lower water-absorbing layers on the upper side of the bottom layer of the sprayed hot-melt structural adhesive layer, and then lay the middle absorbent layer on the upper part of the lower water-absorbing layer;

[0095] 3) Spray the hot-melt structural adhesive la...

Embodiment 2

[0098] The surface layer adopts a width of 10cm and a weight of 30g / m 2 dust-free paper, the upper absorbent layer adopts a weight of 140g / m 2 , 25-mesh polymer water-absorbing resin, the middle absorbent layer adopts a weight of 45g / m 2 The hot air fluffy non-woven fabric, the lower absorbent layer adopts a weight of 140g / m 2 , 80-mesh polymer water-absorbing resin, the bottom layer is 10cm in width and 30g / m in weight 2 dust-free paper; the preparation steps are:

[0099] 1) Place a 2.5cm wide strip baffle on the upper side of the bottom layer in the middle of the width of the bottom layer along its length, and then spray 1g / m2 with a glue sprayer 2 Hot-melt structural adhesive layer;

[0100] 2) Sprinkle the upper and lower water-absorbing layers on the upper side of the bottom layer of the sprayed hot-melt structural adhesive layer, and then lay the middle absorbent layer on the upper part of the lower water-absorbing layer;

[0101] 3) Spray the hot-melt structural a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com