Novel PVC/rubber composite micropore partition board

A PVC resin and separator technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of shortened battery cycle life, easy to be broken or broken, battery failure, etc., to achieve performance improvement, increase porosity and strength , Improve the effect of infiltration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

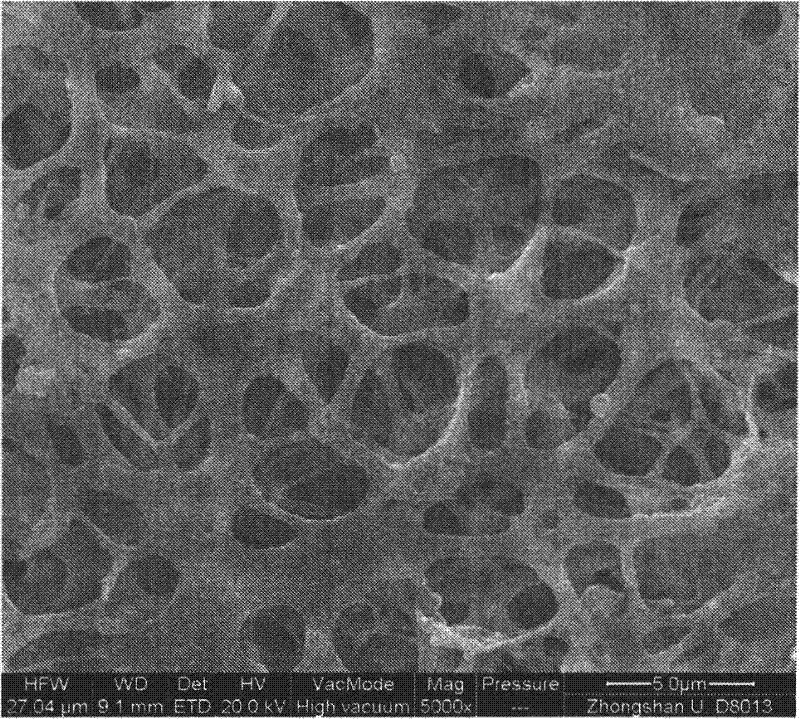

Image

Examples

Embodiment 1

[0040] Weigh dry PVC paste resin 30.0%, chlorinated rubber 20% by weight, specific surface area is 150m 2 / g of hydrophilic nano fumed silica 45%, carbon black 5.0%. Disperse the mixed material into dimethylacetamide, adjust to a viscous liquid with a viscosity of 200,000 Pa.s, and shape it by extruding and calendering at room temperature to make a thin sheet with a thickness of 1.5 mm. After leaching in hot water at a temperature of 60°C, the shape is finalized, and then dried in an oven at 80°C.

Embodiment 2

[0042] Take by weighing 41.4% of the dry good PVC blending resin, 16.3% of the vinyl chloride resin, and the specific surface area is 260m 2 The mixture of hydrophobic nano fumed silica and 250-mesh attapulgite / g is 38.1%, and graphite is 4.2%. Disperse the mixed material into dimethylformamide, adjust to a viscous liquid with a viscosity of 156,000 Pa.s, and shape it by extruding and calendering at room temperature to make a thin sheet with a thickness of 1.0 mm. After leaching in hot water at a temperature of 60°C, the shape is finalized, and then dried in an oven at 80°C.

Embodiment 3

[0044] Take by weight proportion the PVC resin 53.7% that the degree of polymerization that has dried is 1500, chlorinated butyl rubber 13.3%, specific surface area is 190m 2 The mixture of hydrophobic nano fumed silica and 150-mesh precipitated silica / g is 29.6% (the mixing weight ratio is 1:1), and carbon nanofiber is 3.4%. Disperse the mixed material into dimethyl sulfoxide, adjust it to a viscous liquid with a viscosity of 127,000 Pa.s, and shape it by extruding and calendering at room temperature to make a thin sheet with a thickness of 2.4 mm. After leaching in hot water at a temperature of 60°C, the shape is finalized, and then dried in an oven at 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com