Concave-convex hot-air non-woven fabric and application thereof in paper diaper and paper diaper

A technology of hot-air non-woven fabrics and diapers, applied in textiles and papermaking, textile material processing, non-woven fabrics, etc., can solve the problems of fast infiltration speed, too wet, fast absorption speed, etc., and achieve absorption and infiltration speed Fast, dry surface, enhanced water absorption and infiltration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

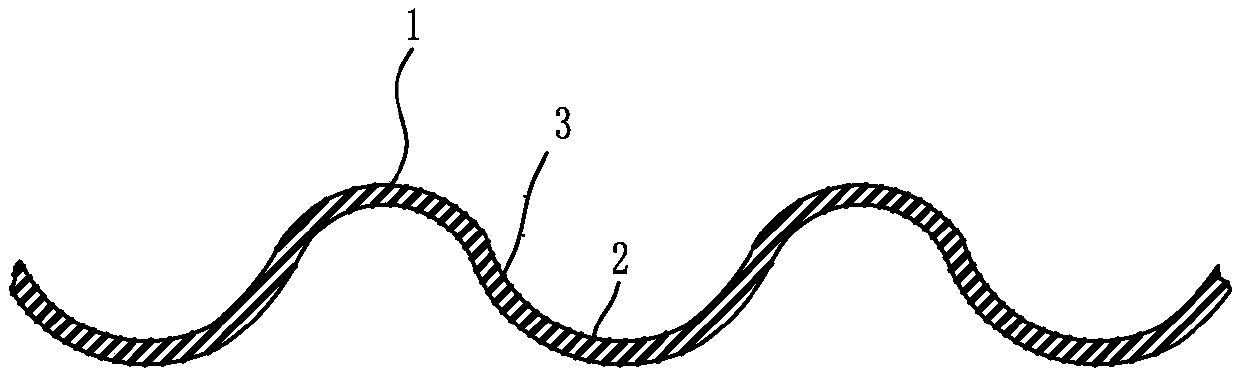

[0023] Such as figure 1 The concave-convex air-through non-woven fabric shown is made of low-melting bicomponent fibers with a linear density of 1.2-6D and a length of 38-65mm. The surface layer is provided with a plurality of convex points 1 that protrude upwards. The convex points 1 are water-repellent. Between the adjacent convex points 1 is an inner concave surface 2. The inner concave surface 2 is hydrophilic. The water repellency of the connecting surface 3 gradually decreases from top to bottom, which not only ensures the comfort of use, but also improves the speed of infiltration, and the surface layer made of it has a good use effect.

[0024] Concavo-convex air-through non-woven fabrics are produced by the following steps in sequence:

[0025] (1) Choose low-melting bicomponent fibers with a linear density of 1.2-6D and a length of 38-65mm, where the bicomponent fiber can be one of PE / PP, PE / PET, PP / PP, CoPET / PET , or a mixture of the two, the two-component structu...

Embodiment 2

[0030] Application of concave-convex air-through non-woven fabric on diapers, the concave-convex air-through non-woven fabric described in Example 1 is used as the surface layer of diapers. The paper diapers comprise an outer cover and a core therein. The outer cover includes a bottom layer and the concave-convex air-through nonwoven fabric described in Example 1. The advantage of the patent paper diaper is that it is comfortable to use and can prevent the occurrence of red buttocks.

[0031] During production, on the diaper production equipment, the concave-convex hot-air non-woven fabric described in Example 1 is unrolled, and the lower non-woven fabric, flow guide layer, composite core body, side leakage-proof partition and anti-seepage bottom film are unrolled. After compounding, dry and comfortable diapers are obtained. For the diapers of this patent, first, multiple hydrophilic low-melting bicomponent fibers are made into multiple hydrophilic air-through non-woven fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com