Method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment

A polyethylene fiber, ultra-high molecular weight technology, applied in the direction of fiber type, fiber treatment, physical treatment, etc., can solve the problem of not mentioning coating UHMWPE fiber, etc., to achieve the optimization of molding process and overall comprehensive performance, and fast processing speed , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Helium plasma treatment of nano-silica sol coated ultra-high molecular weight polyethylene fibers

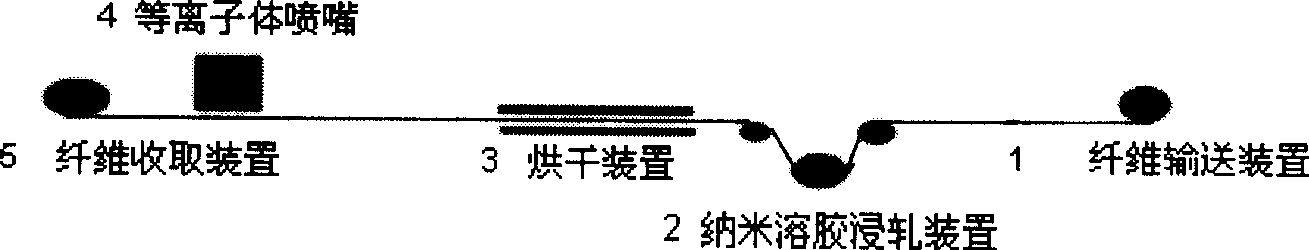

[0041] Such as figure 1 As shown, the ultra-high molecular weight polyethylene fiber 1 to be treated is immersed in a percentage concentration of 0.05% nano-silica sol along the outer circle of the flower basket of the sol padding device 2, and the padding process is carried out, and then the ultra-high molecular weight polyethylene fiber is processed. Introduce into the drying device 3, dry at 60°C and collect the solvent, then the ultra-high molecular weight polyethylene fiber 1 is introduced into the plasma atmosphere area of the plasma nozzle 4 for plasma surface modification treatment, the distance between the upper surface of the fiber bundle and the nozzle is 5MM, the distance between the lower surface of the fiber bundle and the nozzle<20MM, the power is 40 watts, and the processing time is 2 seconds. The processed ultra-high molecular weight polyethylene fiber ...

Embodiment 2

[0044] Oxygen plasma treatment of nano-silica sol coated ultra-high molecular weight polyethylene fibers

[0045] Such as figure 1 As shown, the ultra-high molecular weight polyethylene fiber 1 to be treated is immersed in a percentage concentration of 0.05% nano-silica sol along the outer circle of the flower basket of the sol padding device 2, and the padding process is carried out, and then the ultra-high molecular weight polyethylene fiber is processed. Introduce to drying device 3, dry at 110°C and collect the solvent. Then the ultra-high molecular weight polyethylene fiber 1 is introduced into the plasma atmosphere area of the plasma nozzle 4 to carry out plasma surface modification treatment. The distance between the upper surface of the fiber bundle and the nozzle is 5MM, the distance between the lower surface of the fiber bundle and the nozzle<20MM, and the power is 40 watts. The time is 2 seconds, and the processed ultra-high molecular weight polyethylene fiber 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com