Quaternary ammonium salt modified chitosan microspheres and preparation method and application thereof

A technology of chitosan microspheres and quaternary ammonium salts, applied in the direction of botany equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of high transportation and storage costs, inability to be effectively recovered, and poor bacterial scale action ability , to achieve the effect of broad application prospects, abundant reserves, and non-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

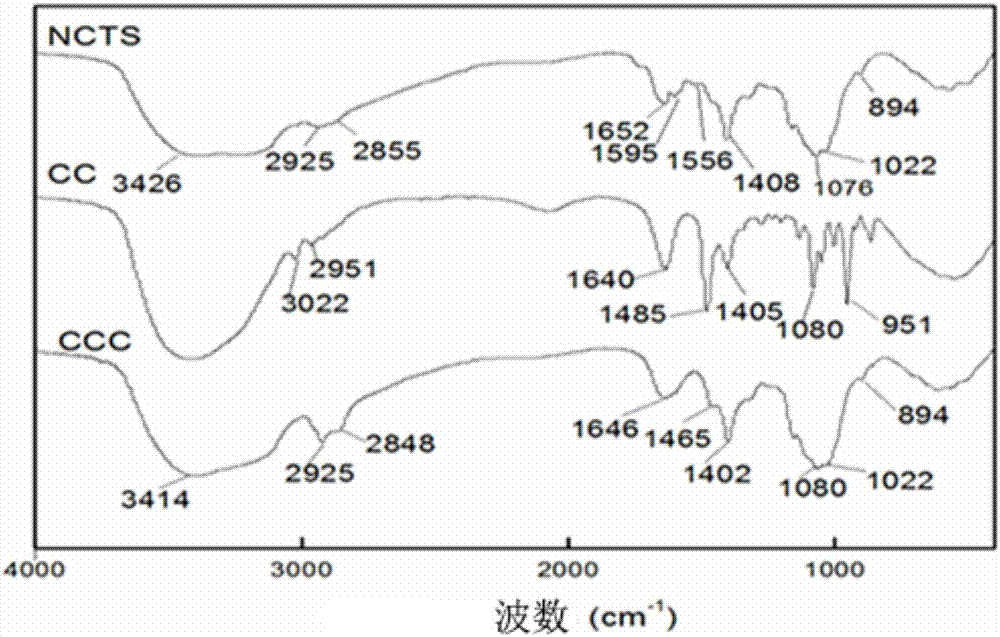

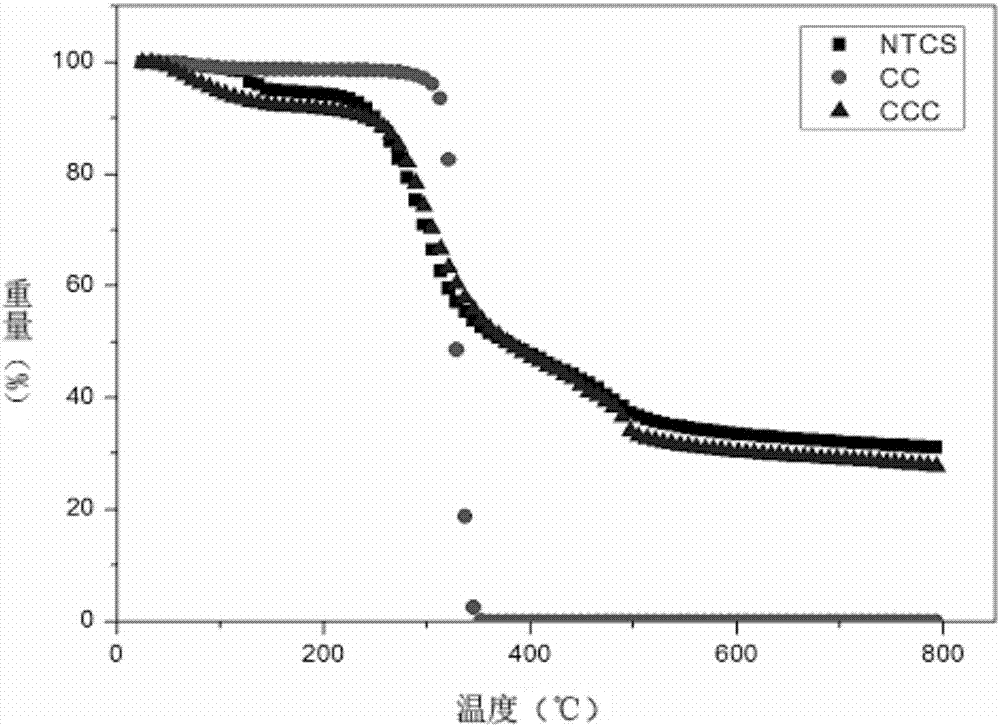

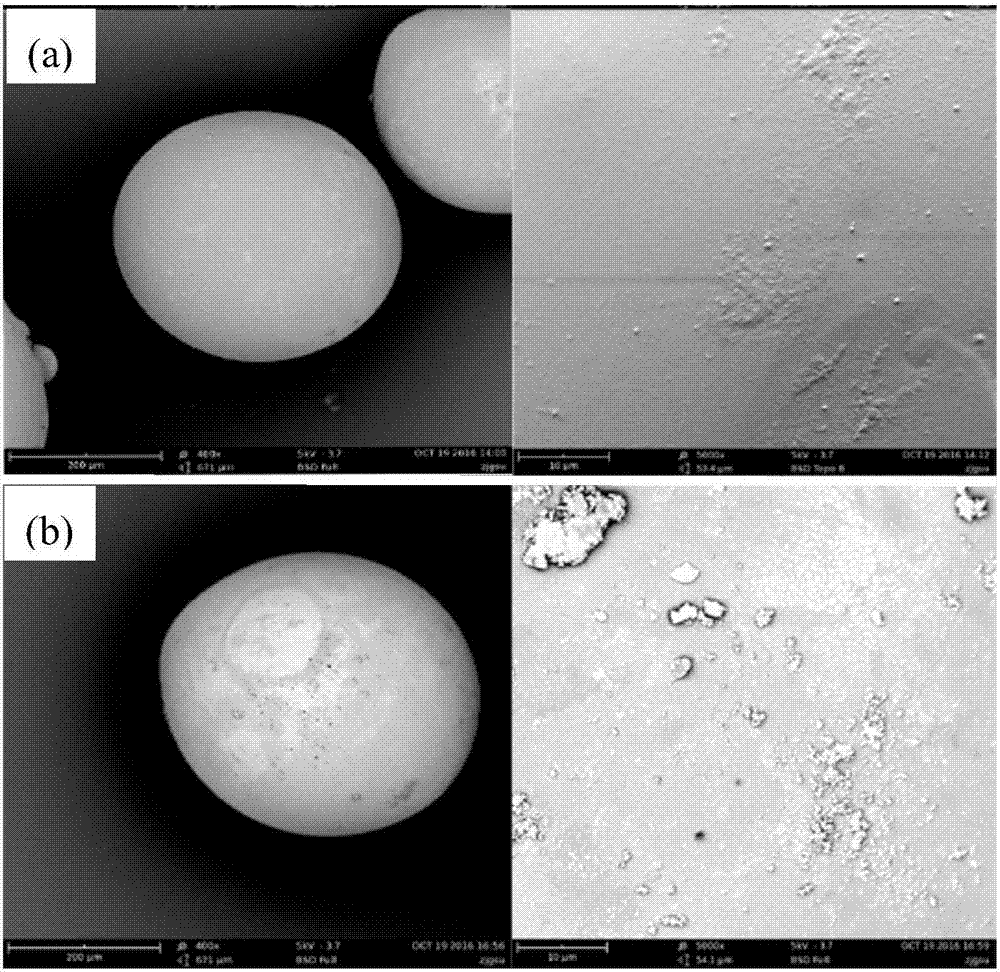

Embodiment 1

[0064] (1) 1.0g chitosan (CTS) is placed in 50ml mass fraction and is 4% acetic acid solution, stirs to dissolving, stirs 15min with 250r / min rotation rate, adds the liquid paraffin of 200mL, is heated up to after stirring 10min again At 50°C, add 4 drops of emulsifier Span80 dropwise, and emulsify for 10 minutes.

[0065] (2) Add 2 mL of formaldehyde in step (1), react at 50°C for 1.5h, then raise the temperature to 70°C, add 10% NaOH aqueous solution dropwise, and adjust the pH of the solution to 9. Afterwards, 4 mL of epichlorohydrin was slowly added dropwise, and after reacting for 5 hours, it was washed with distilled water, then petroleum ether and absolute ethanol in sequence, and then washed with water repeatedly until the pH value reached neutral. Dry to constant weight in a vacuum desiccator at 50°C.

[0066] (3) The cross-linked chitosan microspheres prepared in step (2) were heated to 60° C. for 9 h with 30 mL of 1 mol / L hydrochloric acid aqueous solution. Then w...

Embodiment 2

[0103] (1) 1.0g chitosan (CTS) is placed in 50ml mass fraction and is 4% acetic acid solution, stirs to dissolving, stirs 15min with 250r / min rotation rate, adds the liquid paraffin of 200mL, is heated up to after stirring 10min again At 50°C, add 4 drops of emulsifier Span80 dropwise, and emulsify for 10 minutes.

[0104] (2) Add 2.0 mL of formaldehyde in step (1), react at 50°C for 1.5h, then raise the temperature to 60°C, add 10% NaOH aqueous solution dropwise, and adjust the pH of the solution to 9. Afterwards, 4 mL of epichlorohydrin was slowly added dropwise, and after reacting for 5 hours, it was washed with distilled water, then petroleum ether and absolute ethanol in sequence, and then washed with water repeatedly until the pH value reached neutral. Dry to constant weight in a vacuum desiccator at 50°C.

[0105] (3) Heat the cross-linked chitosan microspheres prepared in step (2) to 70° C. for 9 h with 40 mL of 1 mol / L hydrochloric acid aqueous solution. Then wash w...

Embodiment 3

[0109] (1) 1.0g chitosan (CTS) is placed in the acetic acid solution that 50ml mass fraction is 4%, stirs to dissolving, stirs 15min with 250r / min rotating speed, adds the liquid paraffin of 150mL, is heated up to after stirring 10min again At 50°C, add 4 drops of emulsifier Span80 dropwise, and emulsify for 10 minutes.

[0110] (2) Add 3.0mL formaldehyde in step (1), react at 60°C for 2h, then raise the temperature to 70°C, add 10% NaOH aqueous solution dropwise, and adjust the pH of the solution to 9. Afterwards, 4 mL of epichlorohydrin was slowly added dropwise, and after reacting for 5 hours, it was washed with distilled water, then petroleum ether and absolute ethanol in sequence, and then washed with water repeatedly until the pH value reached neutral. Dry to constant weight in a vacuum desiccator at 50°C.

[0111] (3) Heat the cross-linked chitosan microspheres prepared in step (2) to 70° C. for 9 h with 40 mL of 1 mol / L hydrochloric acid aqueous solution. Then wash w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com