Gas separation functional material and preparation method and application thereof

A functional material and gas separation technology, applied in the field of nanoporous materials, can solve the problems of poor thermal stability and mechanical stability, difficult synthesis, easy to break and other problems, and achieve the effects of good heat resistance, convenient operation and enhanced mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

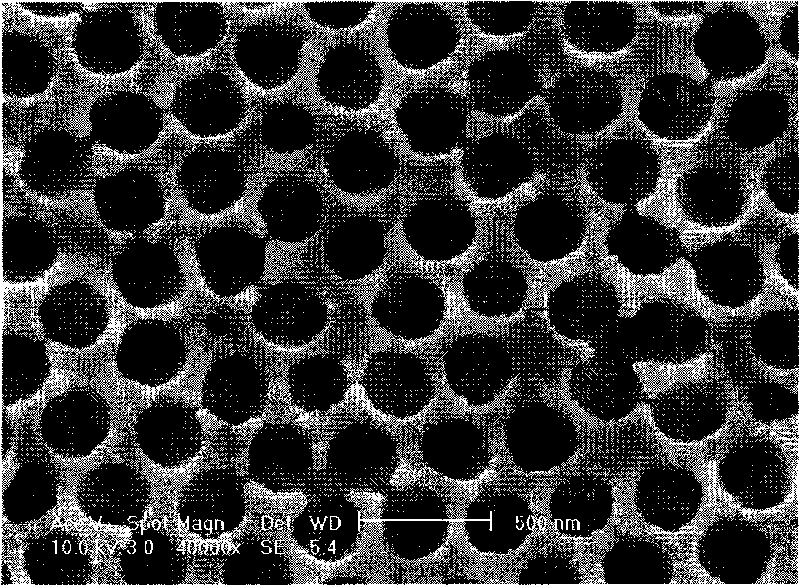

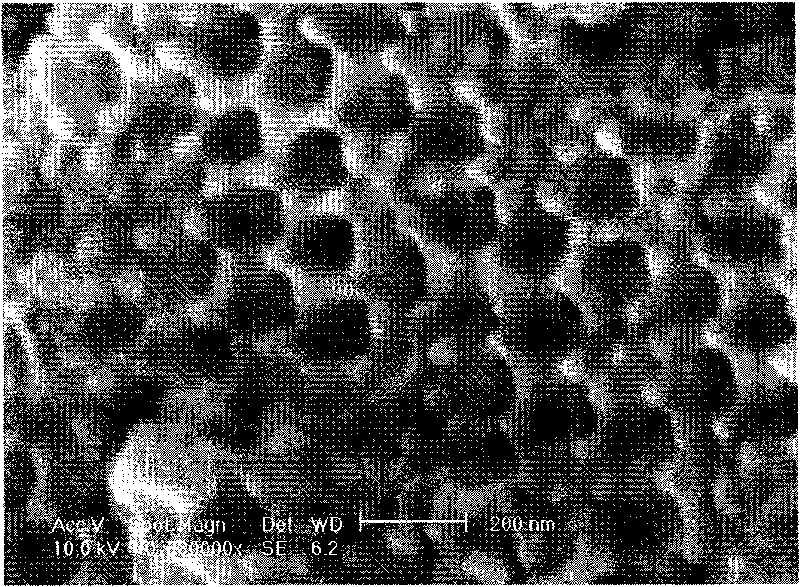

Image

Examples

Embodiment 1

[0035] In a 250ml round bottom three-neck bottle, add 30 grams of water-based nano-iron oxide sol, 70 grams of water-based styrene-butyl acrylate-acrylic acid urethane emulsion with amino functional modification groups obtained by soap-free emulsion polymerization (monomer molar ratio 3: 3: 1), be warming up to 60-80 ℃, stir 2 hours, obtain styrene-butyl acrylate-acrylate urethane polymer / nanometer iron oxide composite emulsion, this emulsion is in 100 ℃ drying for 5 hours to obtain nanoporous gas separation functional materials with amino groups, which can be used for CO 2 、H 2 S, SO 2 , NO 2 Separation and enrichment of acidic gases.

Embodiment 2

[0037] In a 250ml round bottom three-neck bottle, add 20 grams of nano-calcium carbonate sol, 100 grams of polyurethane-hydroxyethyl acrylate-styrene emulsion (monomer molar ratio 2: 1: 7) obtained by emulsion polymerization, and ultrasonically stir for 30 Minutes to obtain polyurethane-hydroxyethyl acrylate-styrene polymer / nano-calcium carbonate composite emulsion. Dry the emulsion at 200°C for 5 minutes to obtain a nano-porous gas separation functional material with carbonate groups, which can be used for H 2 O, NH 3 Separation and enrichment of other gases.

Embodiment 3

[0039] In a 250ml round-bottomed three-necked bottle, add 70 grams of nano-titanium dioxide sol, 100 grams of epoxy-benzyl methacrylate-styrene-acrylamide emulsion (monomer molar ratio 4: 1: 3) obtained by miniemulsion polymerization : 2), stirred at room temperature for 24 hours to obtain epoxy-benzyl methacrylate-styrene-acrylamide polymer / nano-barium hydroxide composite emulsion, and this emulsion was dried at 80°C for 10 hours to obtain Nanoporous gas separation functional materials for CO 2 Separation and enrichment of gases such as gases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com