Air tightness detection system

A technology of air tightness detection and air tightness detection, which is applied in the direction of fluid tightness test, liquid tightness measurement using liquid/vacuum degree, measuring device, etc. It can solve problems such as difficult cleaning, achieve automatic improvement, and clear judgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

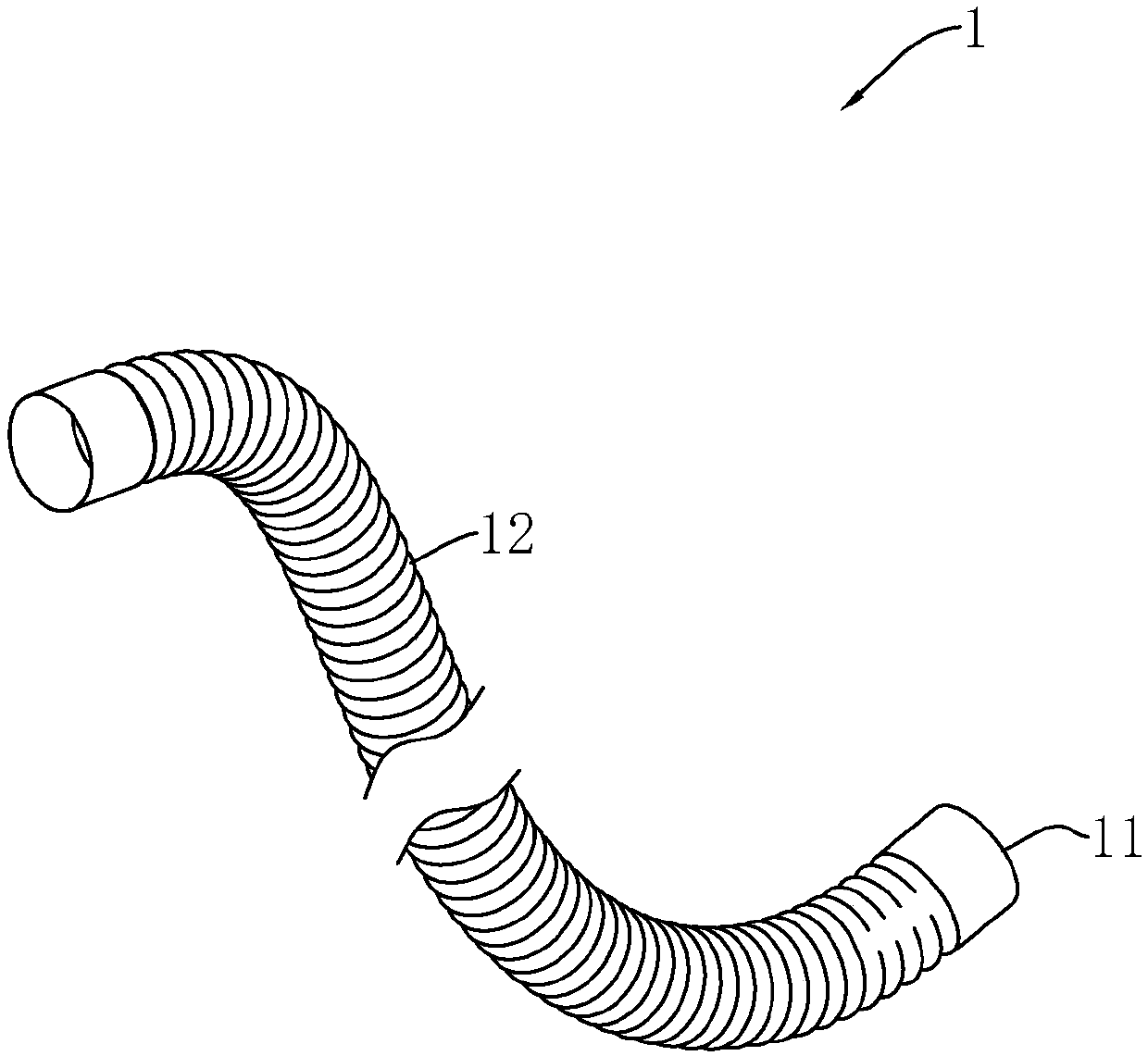

[0037] An airtightness detection joint provided in this embodiment has a structure as shown in the figure.

[0038] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

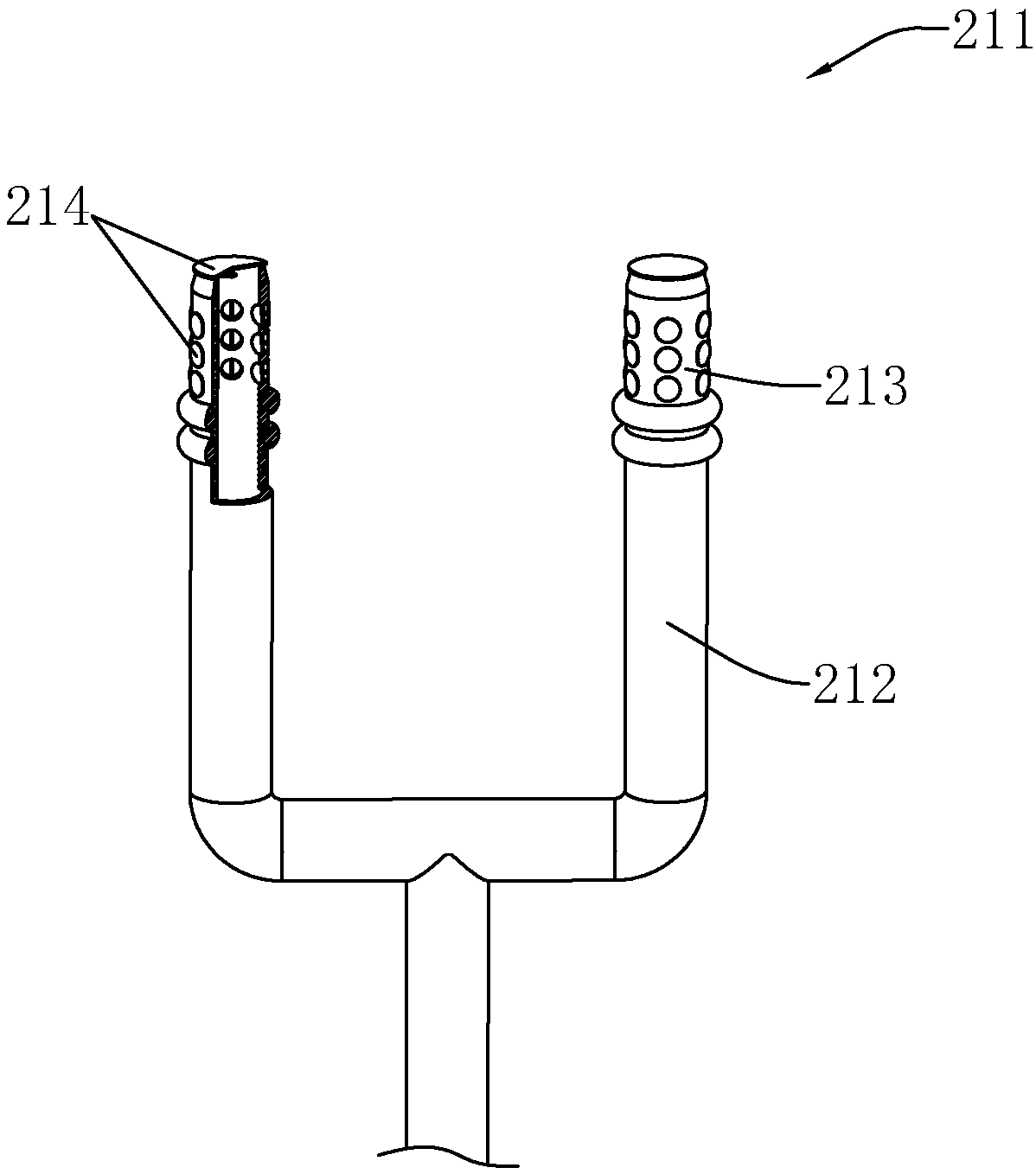

[0039] The leak-tight test connector, including,

[0040] Inflatable pipe 212, one end is used to insert into the seam 11 of the bellows, and the other end is connected to the blower;

[0041] Inflatable ports are distributed on the tube body where the inflatable tube 212 is inserted into the mouth 11;

[0042] The check valve 214 is located on the inflation port, allowing airflow to enter the bellows from the inflation pipe 212, and preventing the airflow from enteri...

Embodiment 2

[0053] An air tightness detection joint, the difference from Embodiment 1 is that the guide surface 2124 extends around and forms a retaining edge 2125 that blocks the non-return valve 214 .

Embodiment 3

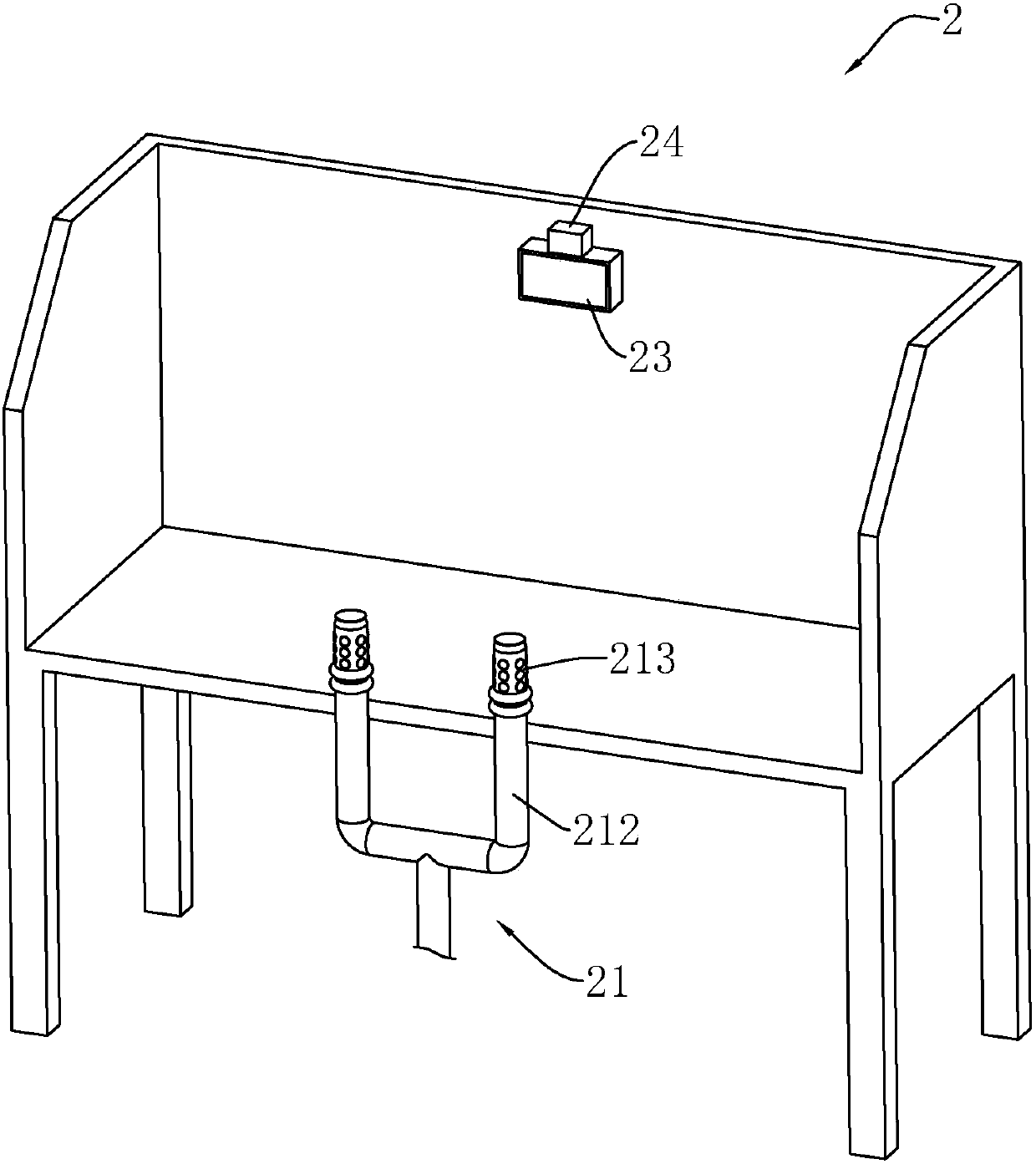

[0055] An airtightness detection platform, comprising the airtightness detection joint of embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com