Manufacturing technology for artificial stone closestool

A manufacturing process and artificial stone technology, applied in the field of sanitary ware, can solve the problems of large discharge of waste gas and waste water, and achieve the effects of less discharge, less environmental pollution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

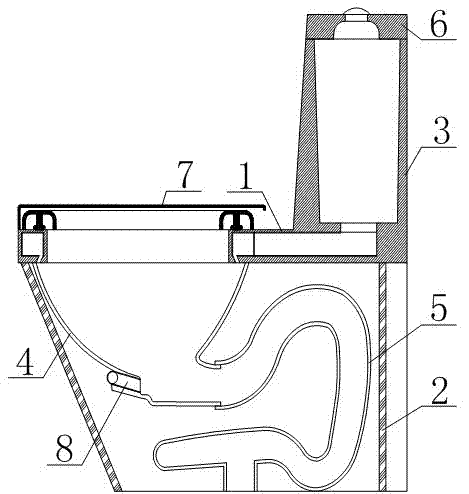

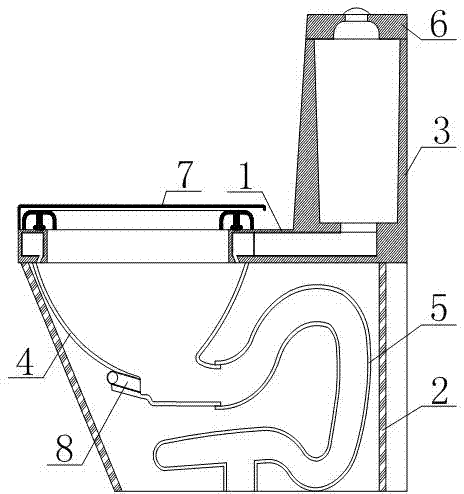

[0028] Such as figure 1 As shown, the manufacturing process of the artificial stone toilet includes the following steps: manufacturing the toilet seat, liner, seat cover and water tank cover; manufacturing the base; connecting the seat of the toilet seat with the liner; connecting the base with the toilet seat ; Assemble the flushing assembly in the water tank of the toilet seat, and connect the water tank cover plate and the seat ring cover plate with the toilet seat.

[0029] Making the toilet seat, liner, seat cover and water tank cover includes the following steps: making the toilet seat FRP mold, liner FRP mold, seat according to the shape and size of the toilet seat, liner, seat cover and water tank cover FRP mold for ring cover plate and FRP mold for water tank cover plate; 35~45% unsaturated epoxy resin and 55~65% heavy calcium powder are mixed according to the weight ratio, and accelerators and curing agents are added as auxiliary materials during the mixing process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com