Manufacturing method of gas cylinder steel tube for long-tube trailer

A manufacturing method and steel pipe technology, applied in the direction of metal material coating process, etc., can solve the problems of large consumption of raw materials, low production efficiency, poor processing accuracy, etc., and achieve the effect of good quality, low cost, and reduced raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: with φ 559mm * 20mm, length is: 10000mm, material is the rough tube of 4130X (material is to adopt 4130 in ASTM A519 standard), produces the gas cylinder steel pipe for long tube trailer, and finished tube specification is: φ 559mm * 16.5mm.

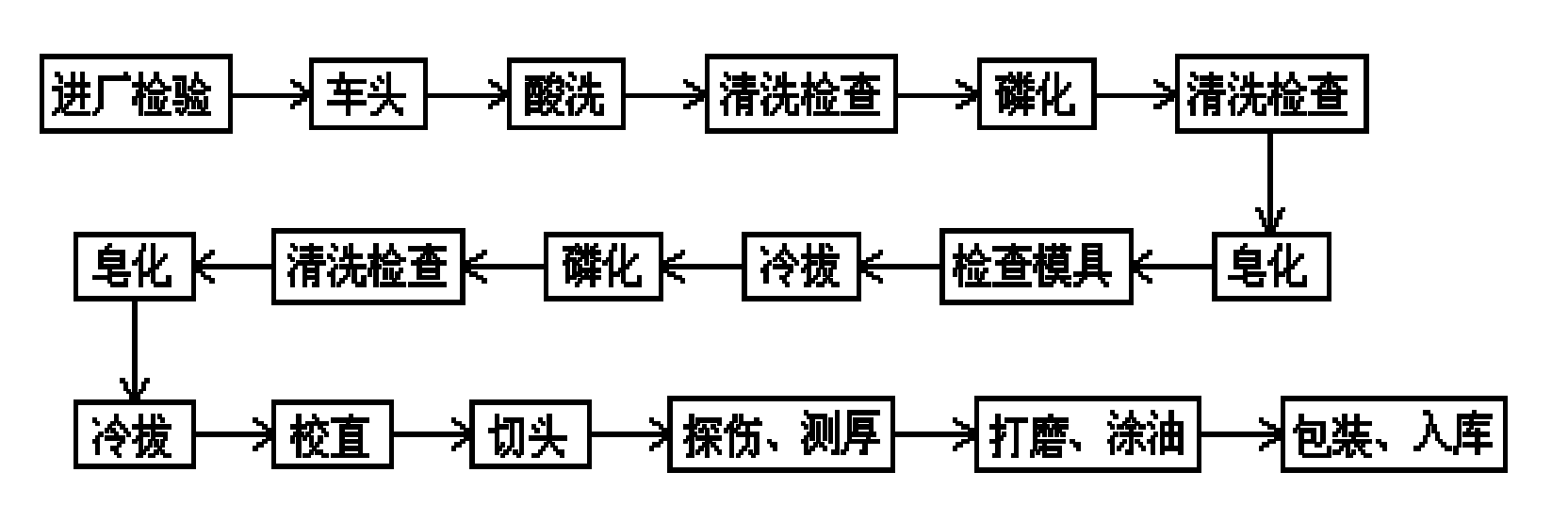

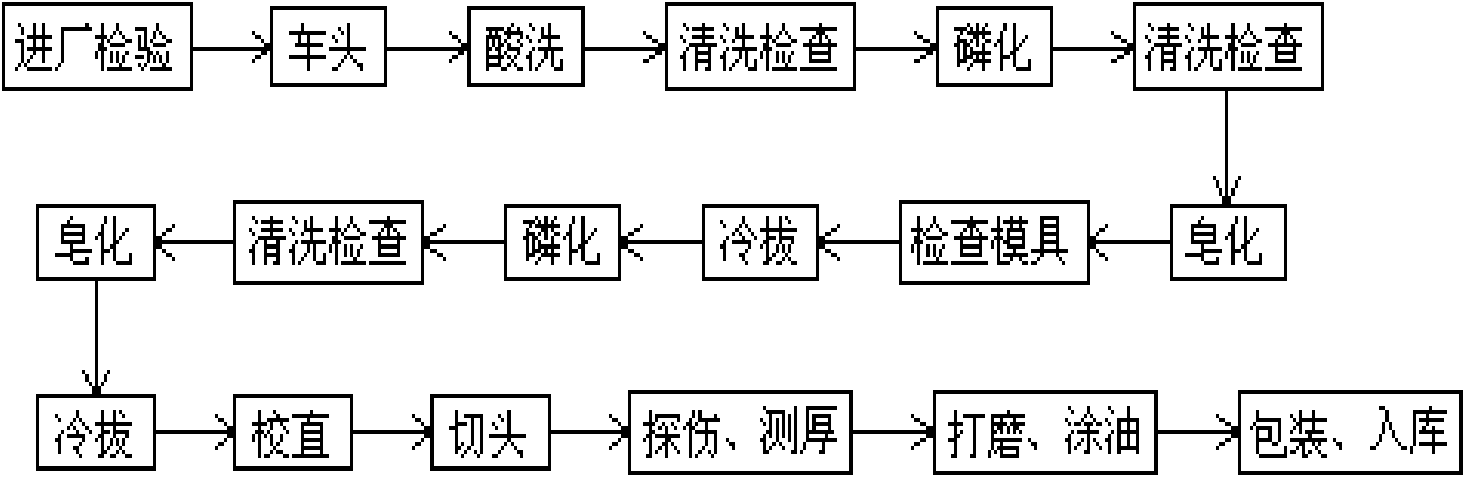

[0033] like figure 1 As shown, the process is as follows:

[0034] (1) First check whether the blank tube is qualified, and then chuck the qualified blank tube;

[0035] (2) Carry out pickling treatment on the blank tube. During pickling, the scale on the inner and outer surfaces of the blank tube should be completely removed. The pickling time is 25-40 minutes. If the ambient temperature is lower than 10°C, the acid solution should be heated to 18°C above;

[0036] (3) Lift the pickled steel pipe to the washing station, raise one end of the steel pipe by 300-320mm, and roll and wash the inner and outer surfaces of the steel pipe until no sewage flows out from the inner surface of the steel pipe;

[0037] (4) Treat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com