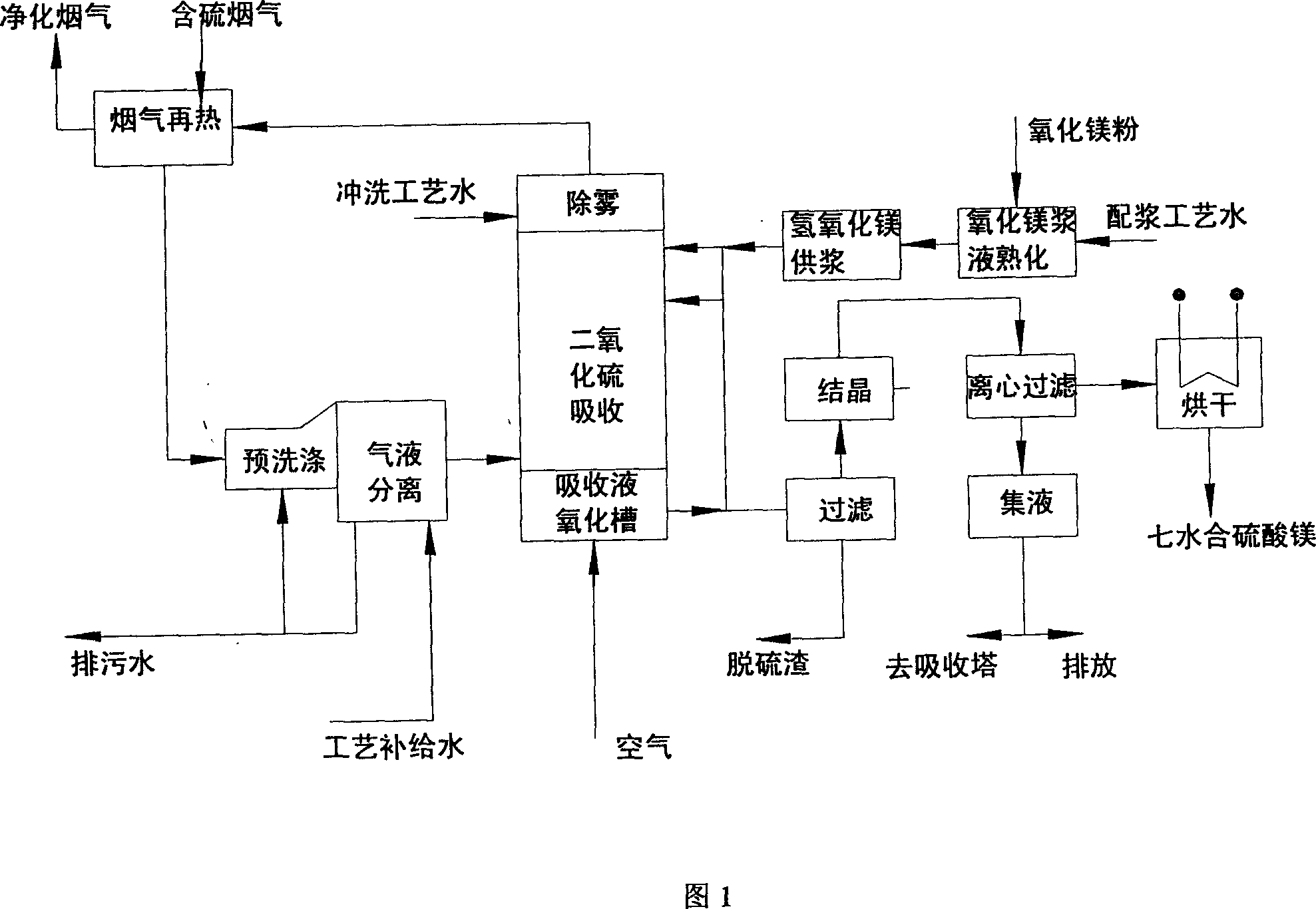

Magnesium oxide flue gas desulfurization and outgrowth thick-slurry method oxidation reclaim process

A technology of magnesium oxide and magnesium oxide powder, which is applied to chemical instruments and methods, magnesium sulfate, separation methods, etc., can solve the problems of high energy consumption and large liquid volume, and achieve small equipment investment, high efficiency, and facilitate transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

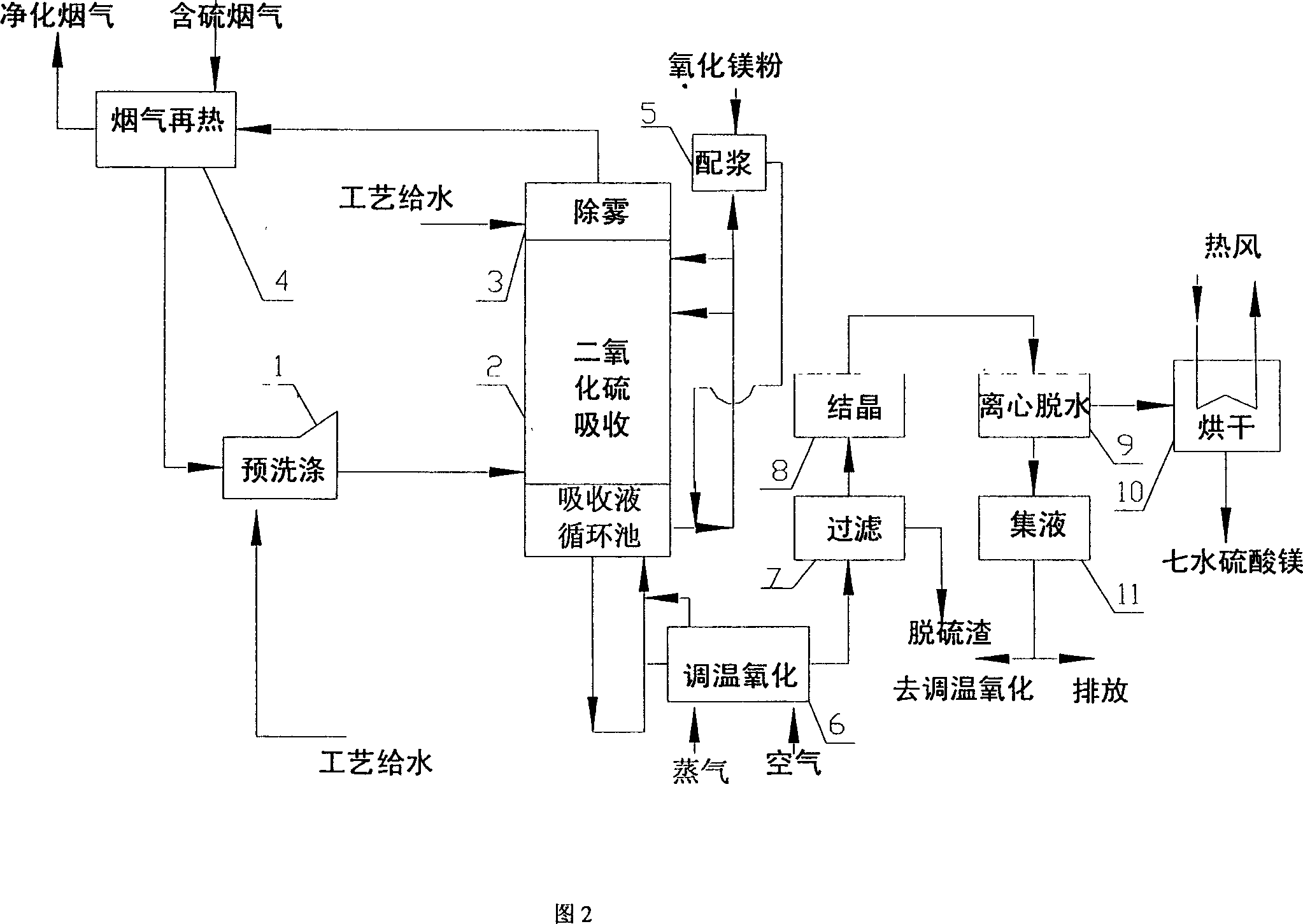

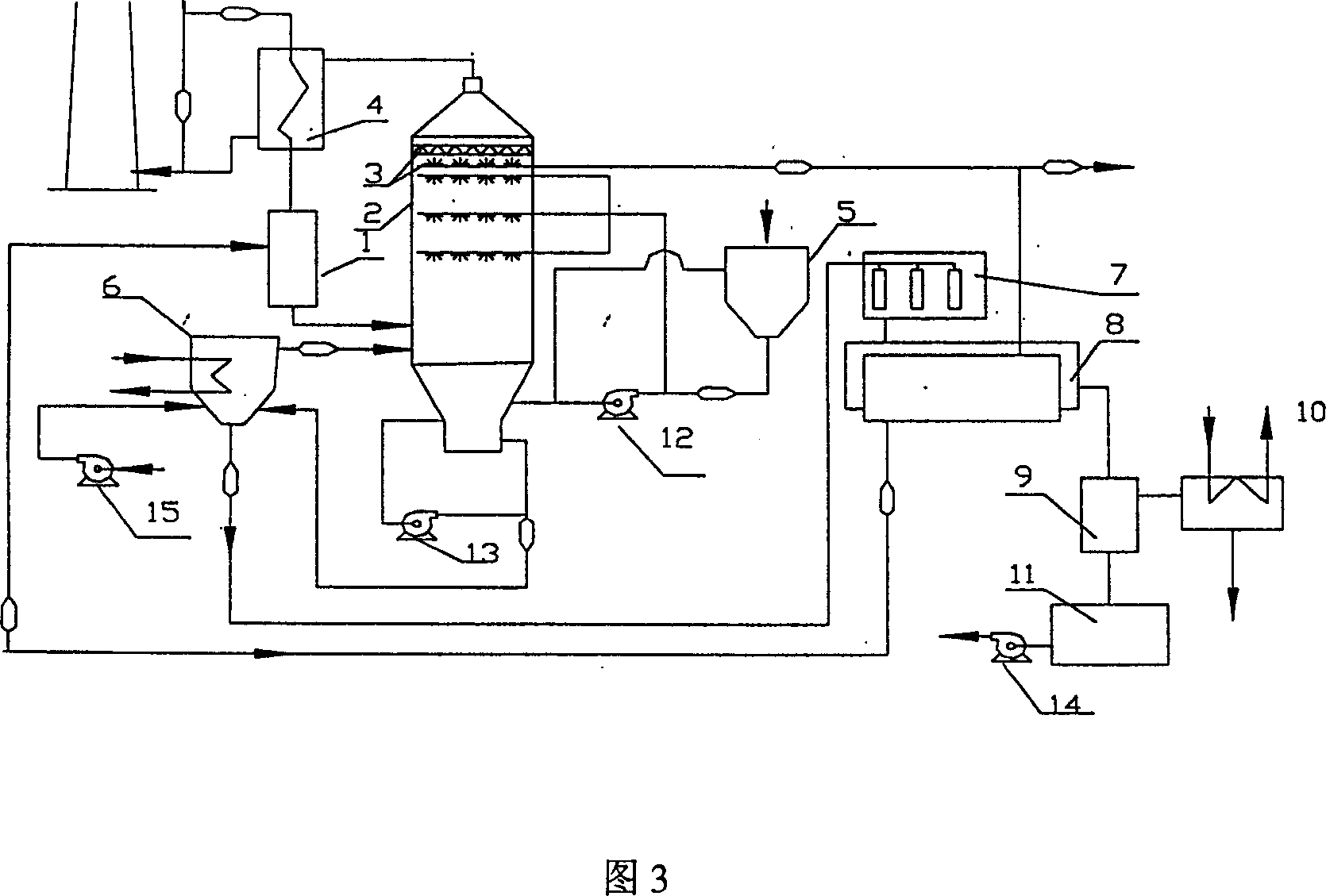

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] As shown in Figure 2 and Figure 3, the sulfur-containing flue gas from the boiler after electrostatic precipitator is cooled by the flue gas reheating device 4, and then enters the pre-washing tower 1 for pre-purification and cooling. The pre-washed flue gas enters the SO 2 The absorption tower 2 desulfurizes, and then passes through the mist removal device 3 and the flue gas reheating device 4, leading to the chimney to be emptied. The magnesia powder used as desulfurization agent is first mixed with circulating absorption liquid in the magnesia slurry mixing tank 5, and a small stream of high-pressure fluid is drawn from the outlet side of the circulating pump 12 and enters tangentially from the bottom side of the slurry mixing tank to form and stir the paddles. The upward swirling flow rotating in the same direction does not cause deposition under the blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com