Novel technology for continuously producing nano powder by using ultra-high temperature plasma and preparation process thereof

A plasma and nano-powder technology, applied in the direction of plasma, chemical/physical/physical-chemical process of applying energy, electrical components, etc., can solve the problems of low utilization rate of plasma energy, low energy utilization, complex equipment, etc. Achieve the effect of reducing the amount of nano-metal powder, avoiding energy waste, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

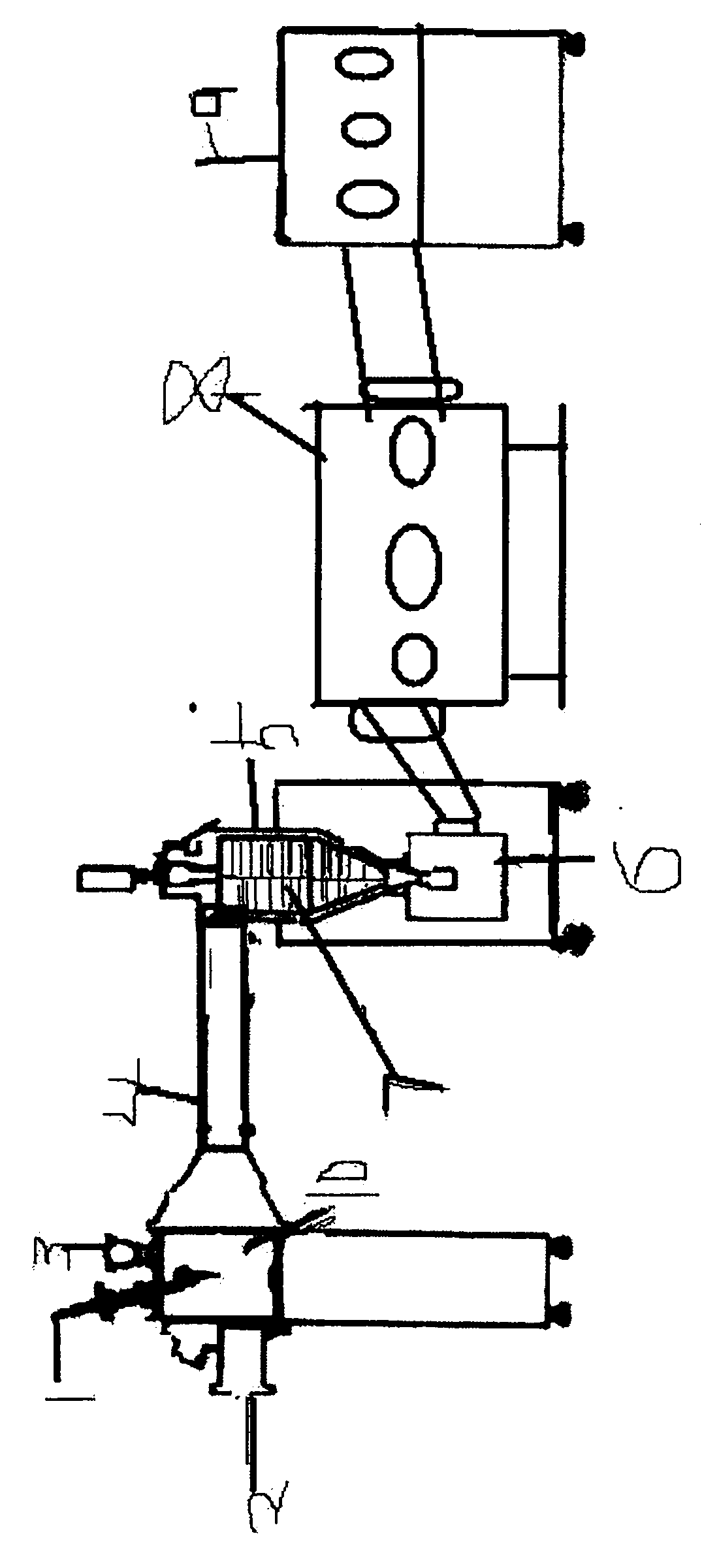

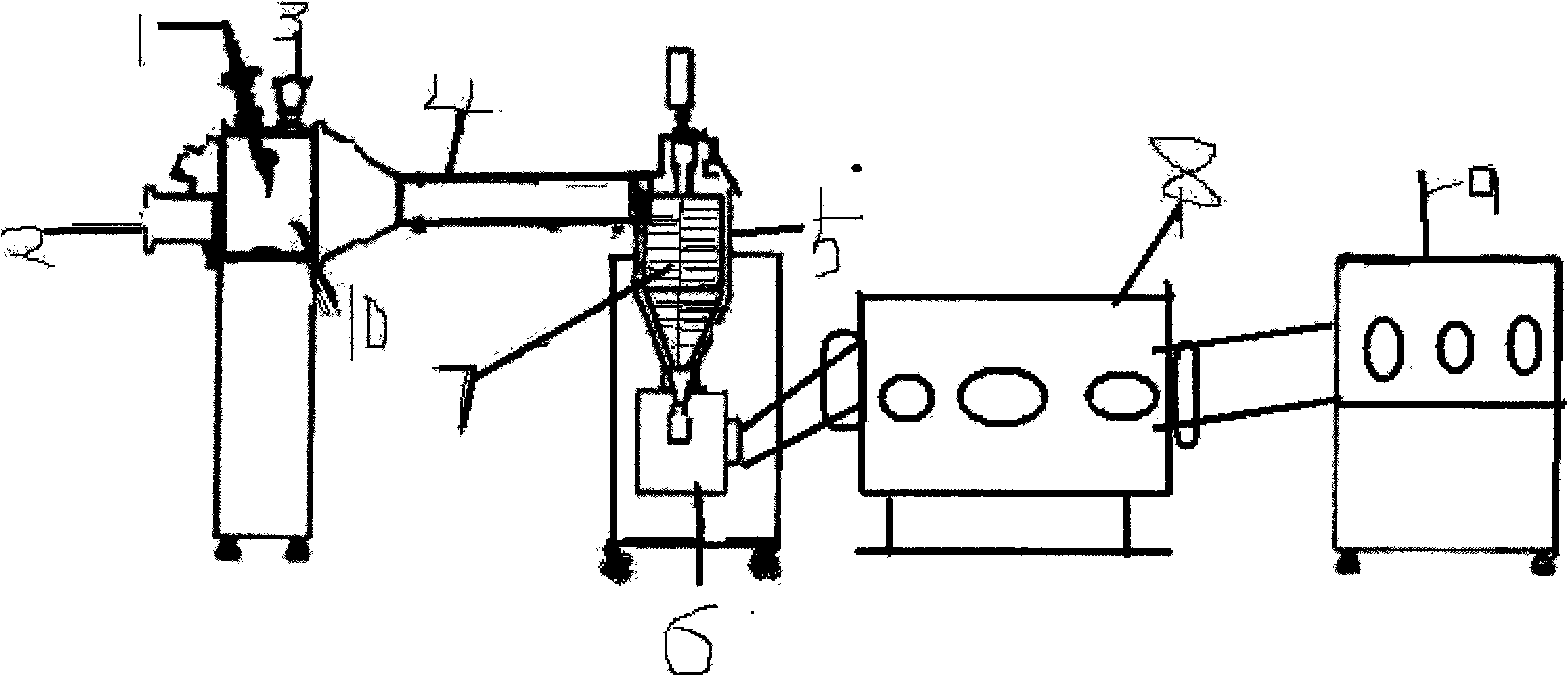

[0036] Working process of the present invention is:

[0037] 1. Seal and evacuate the vacuum powder making chamber, and the vacuum measurement system stops after reaching the set vacuum degree (2.5*10-4Pa);

[0038] 2. Fill in the specific gas (Ar.N2.He.H2.NH3.CH4) for the production of nano-metal powder and stop when the set pressure is reached;

[0039] 3. Turn on the cooling water circulation system; 4. Turn on the nano metal powder cleaning system; 5. Turn on the nano metal powder collection system;

[0040] 6. Turn on the plasma power supply system; 7. Turn on the plasma gun system; 8. Turn on the plasma gun feeding system;

[0041] The ultra-high temperature compression arc (16000-32000K) generated by the plasma gun directly vaporizes the metal powder passing through the plasma gun to generate high-temperature metal vapor. Collision with large air volume gas molecules and the inner wall of the water cooling cycle loses energy, forms clusters, condenses into nano metal po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com