Multi-angle inclined burr removal machine

A tilting and deburring machine technology, which is applied to machine tools, metal processing equipment, and manufacturing tools suitable for grinding the edge of workpieces, can solve the problems of high manufacturing precision, large investment in equipment, and inconvenient loading and unloading of equipment. The effect of equipment investment, reduced production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

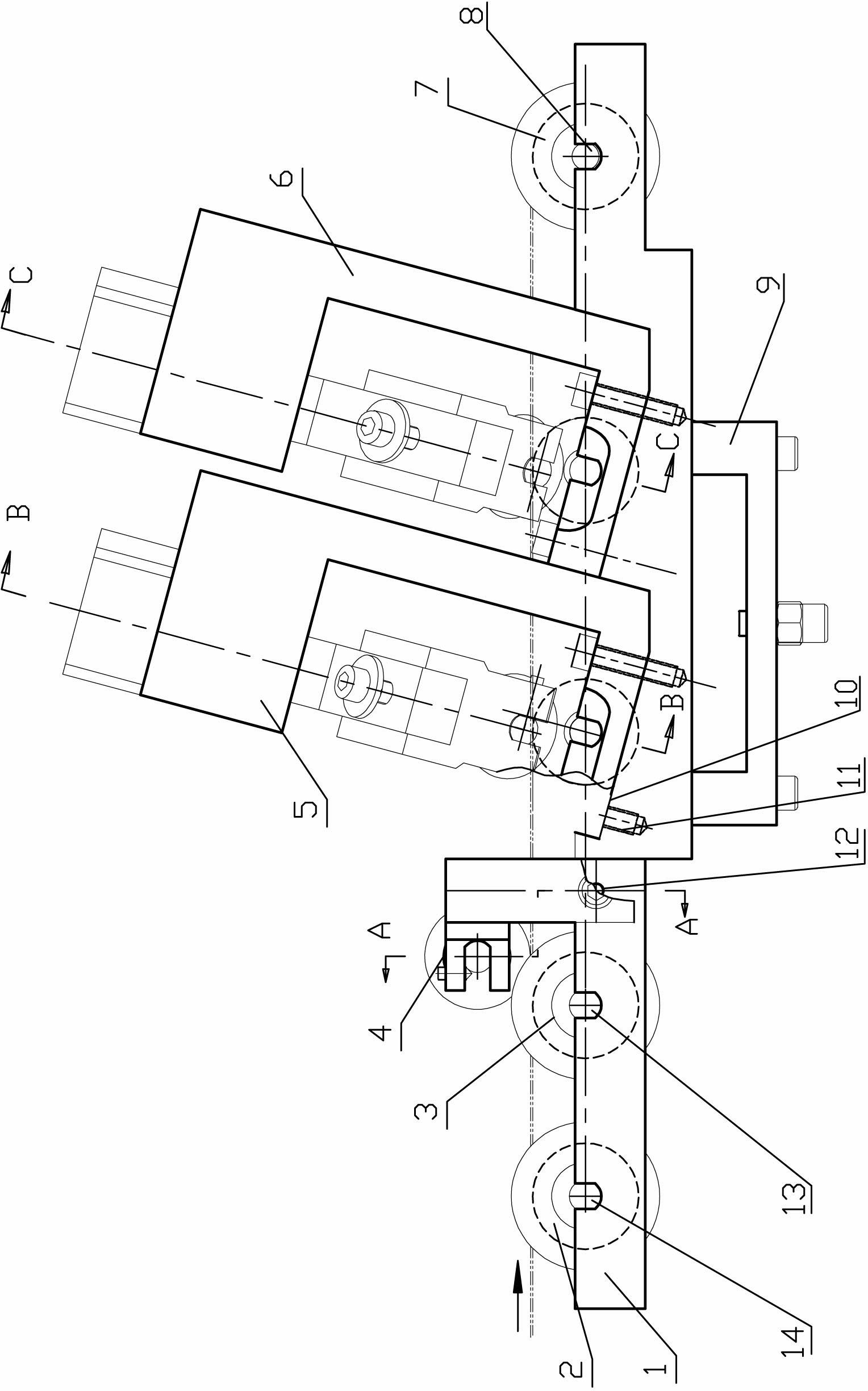

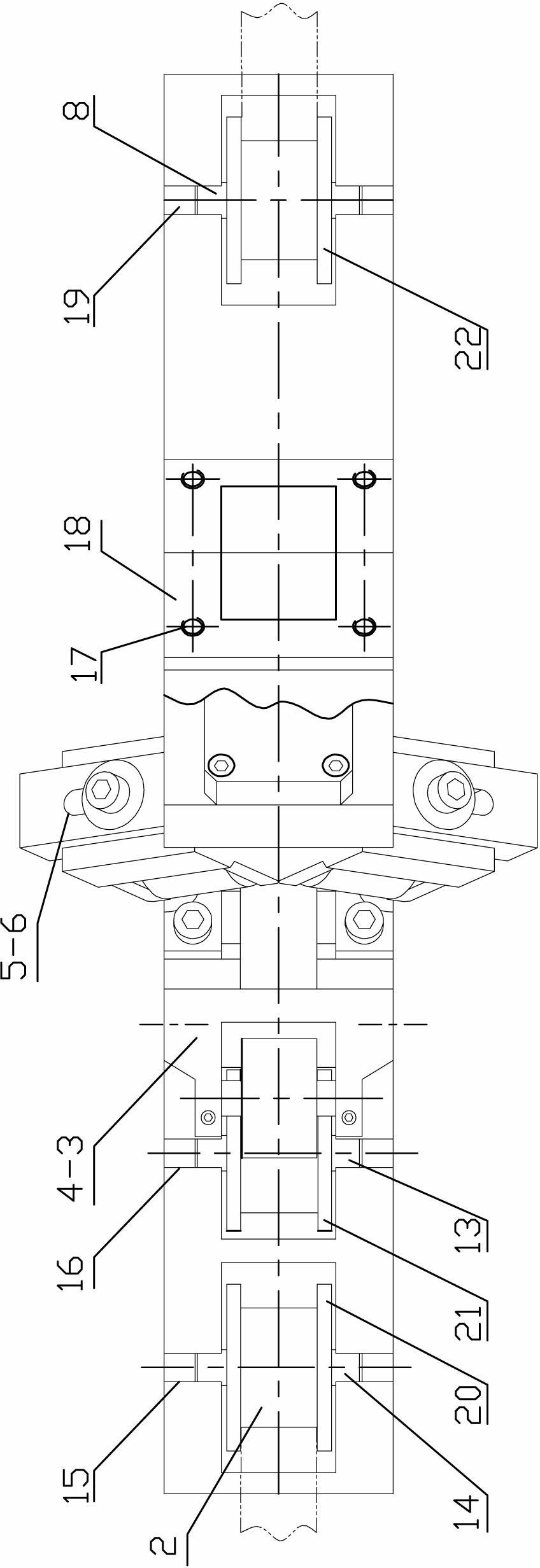

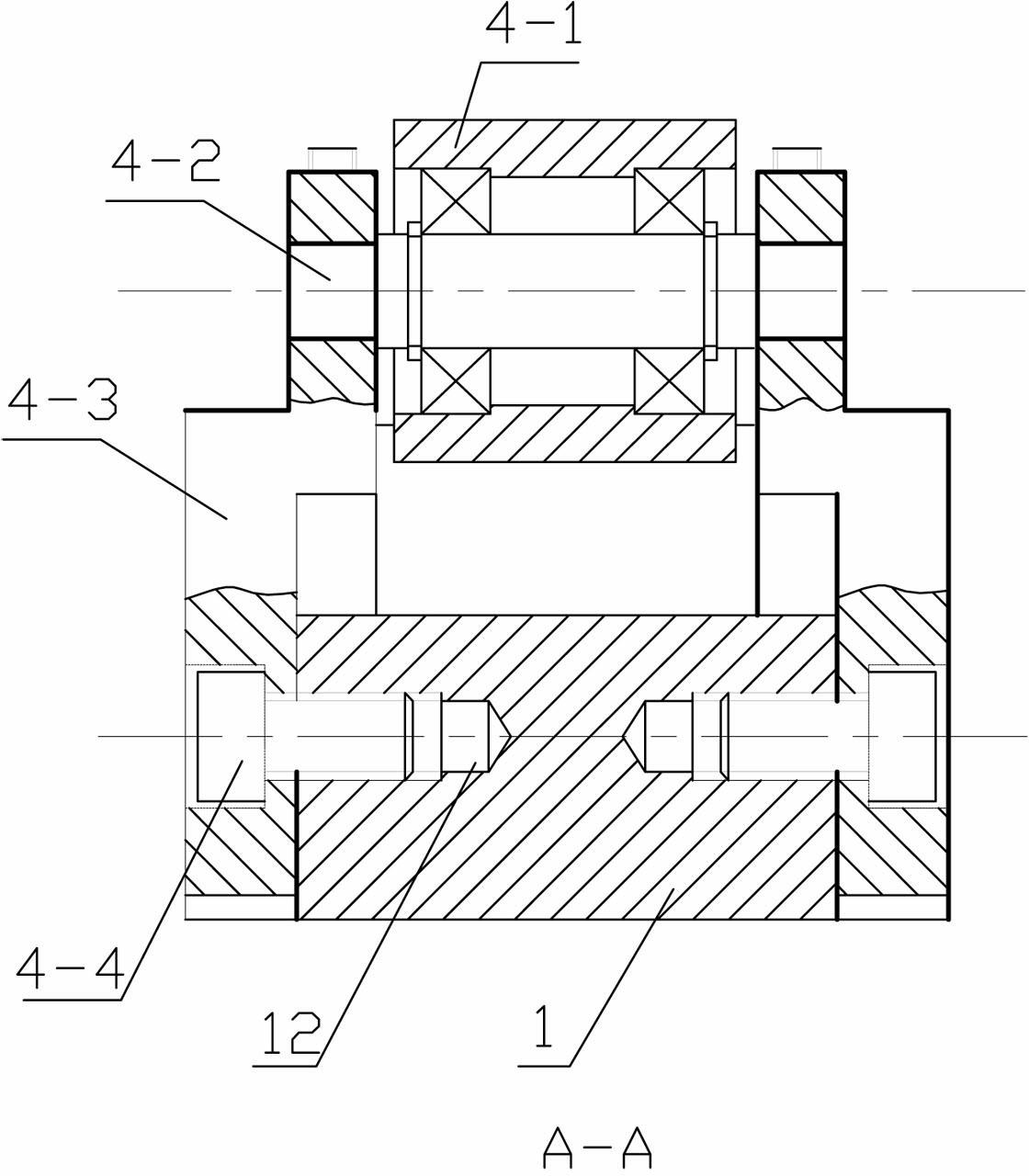

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0039] Such as figure 1Shown: the multi-angle tilting deburring machine of the present invention is characterized in that the base 1, the steel belt input guide wheel, the steel belt conveying roller, the steel belt conveying pressure wheel 4, and the steel belt I The first deburring device 5, the steel belt II deburring device 6 and the steel belt output guide wheel, the steel belt for packaging from the production, processing and cutting process passes through the steel belt input guide wheel, the steel belt conveying roller and the steel belt. The belt conveying pressure roller 4 is introduced to the 5th place of the strip I deburring device, and the first deburring treatment process is performed on the sheared edges of the steel strip on both sides. When it runs to the steel strip II deburring device 6, the The second deburring treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com