Plastic covered agricultural implement and forming method thereof

A farm tool and square technology, applied in the field of tool handles, can solve the problems of high precision of solid wood surface treatment, low product quality level, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

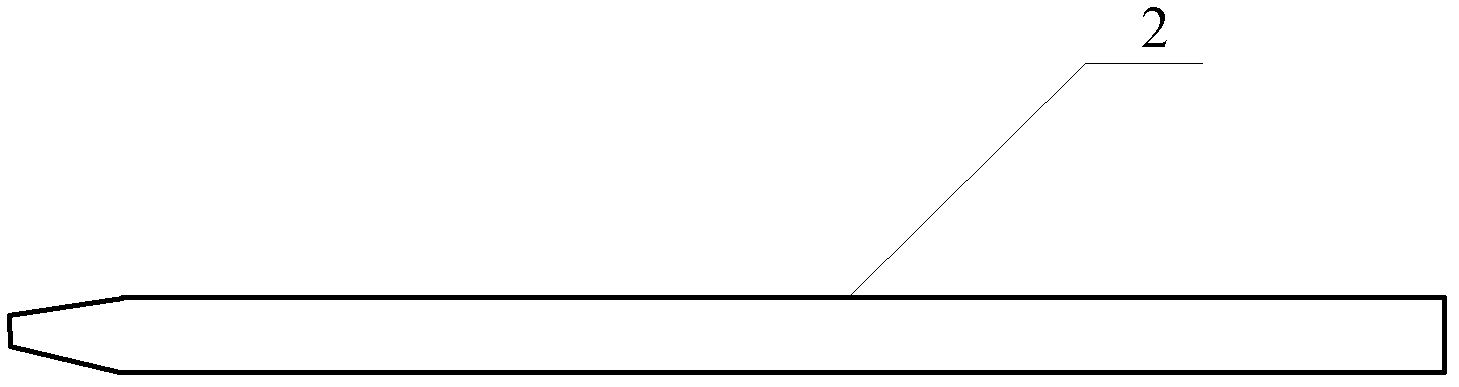

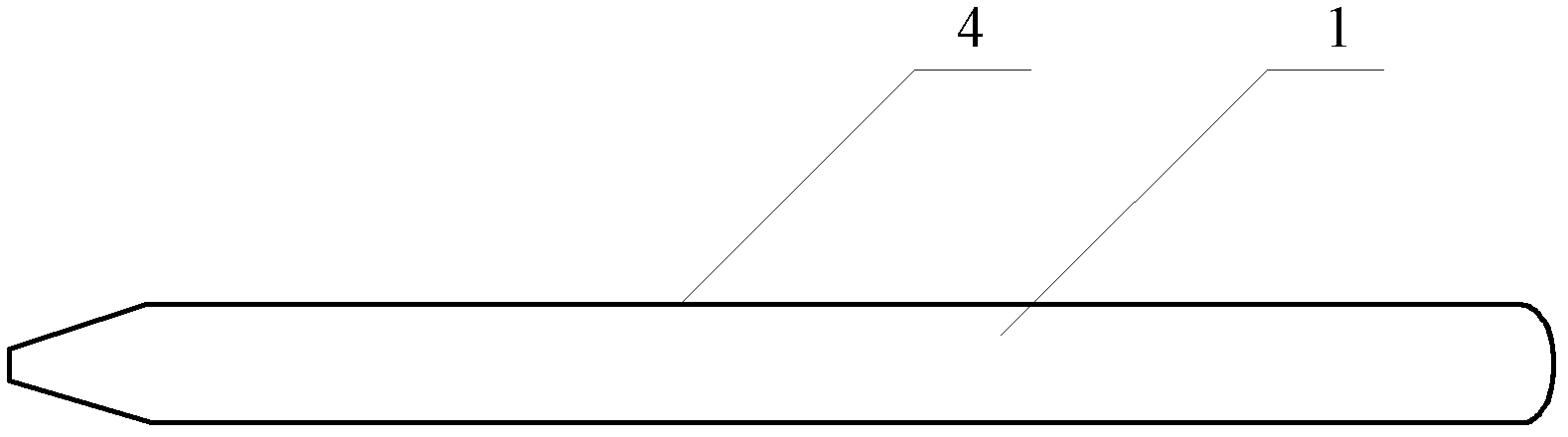

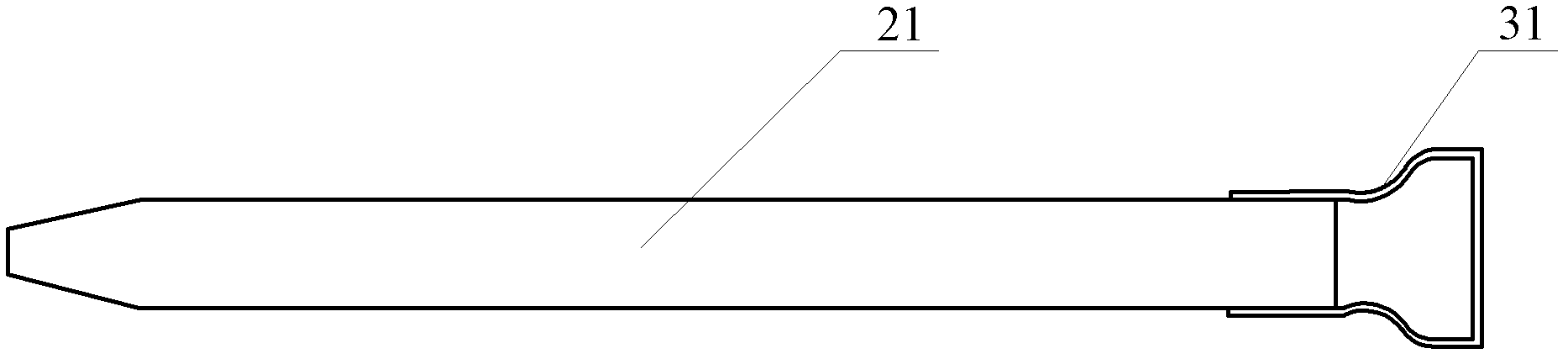

[0029] The solution of the embodiment of the present invention is mainly: use solid wood or wood plywood, bamboo plywood to process it into a circular, oval or square tool handle shape with a diameter of about 15mm ~ 45mm, and install it at the handshake of the tool with a thickness of about 0.8mm ~ 3mm, 8mm~30mm wide steel bar is molded to the shape of the handshake, fixed at the end of the handle with solid rivets as the handshake steel skeleton, so that it is integrated with the handle body, and then a large-tonnage injection molding machine is made of high-strength plastics such as polypropylene or The polyethylene plastic molds and completely covers the entire handle at one time. The handle is completely sealed, completely waterproof, and will not appear moisture, mildew, insects, breakage, etc., which improves the service life of the tool handle.

[0030] Because the tool handles produced by the existing technology are easy to regain moisture, mold, moth, break, and have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com