Mechanical-hydraulic compound transmission mechanism

A compound transmission and hydraulic transmission technology, applied in the direction of mechanical equipment, transmission devices, fluid transmission devices, etc., can solve problems such as operational errors, complex structures, and difficulty in mastering, and achieve the effects of enhanced traffic capacity, high transmission efficiency, and increased load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

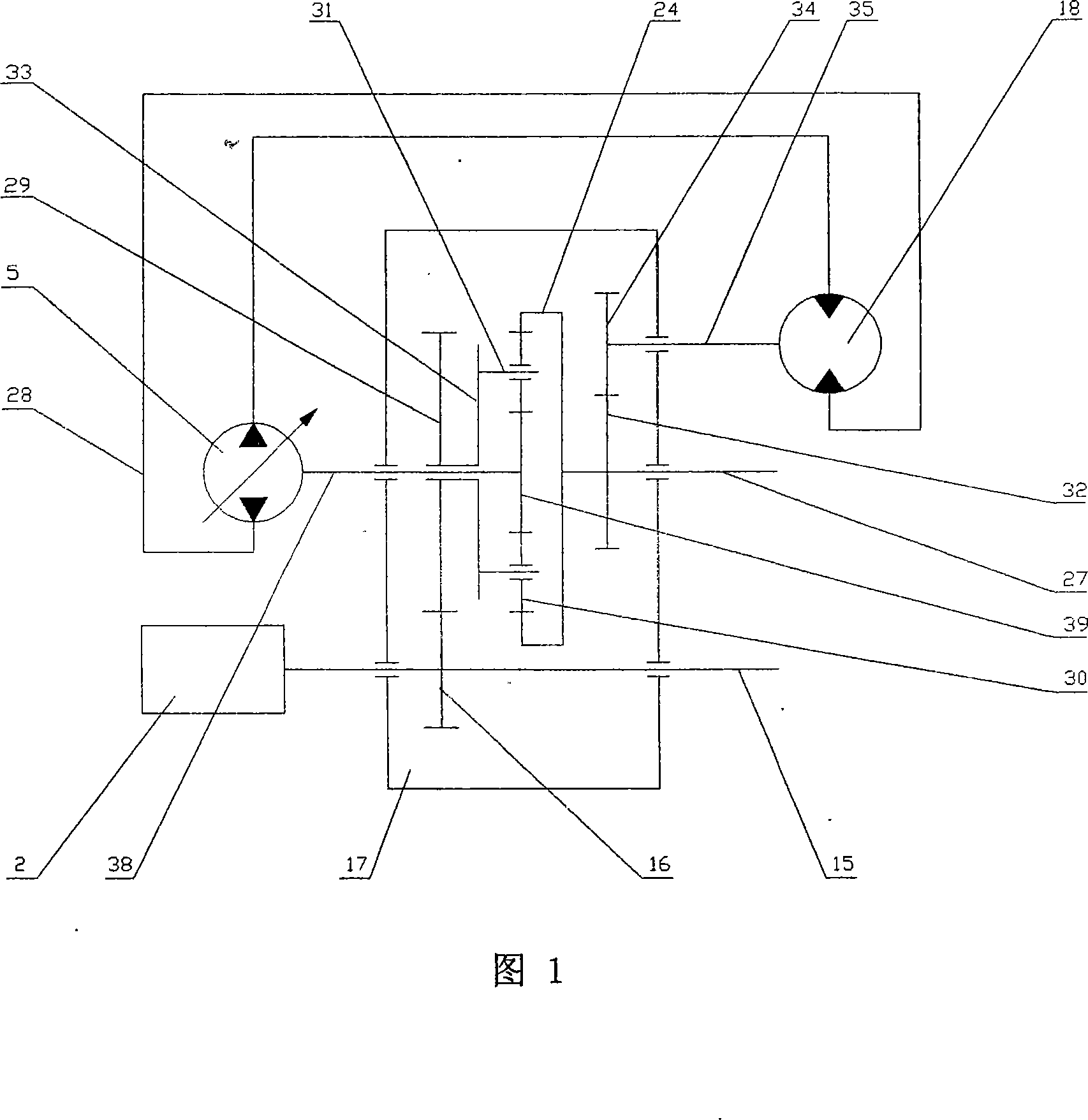

[0052] This embodiment is the application of the mechanical-hydraulic compound transmission mechanism of the present invention in the transmission system of large-scale equipment, which will be described in detail with reference to FIG. 1 .

[0053] The engine 2 is connected to the transmission machinery-hydraulic composite transmission mechanism, and the half shaft 27 is connected to the transmission load working machine; the engine 2 is connected to the transmission transfer shaft 15 to rotate, and the transfer shaft 15 is linked and fastened and installed on the transfer shaft 15 in the planetary gearbox 17 The transfer gear 16 rotates, the transfer gear 16 meshes with the transmission transition gear 29 to rotate, the transition gear 29 is linked with the rotating arm 33 that is tightly connected to rotate, and the rotating arm 33 is linked to two or three planetary gears installed vertically and evenly at the output end of the rotating arm 33 The shaft 31 rotates and drive...

no. 2 example

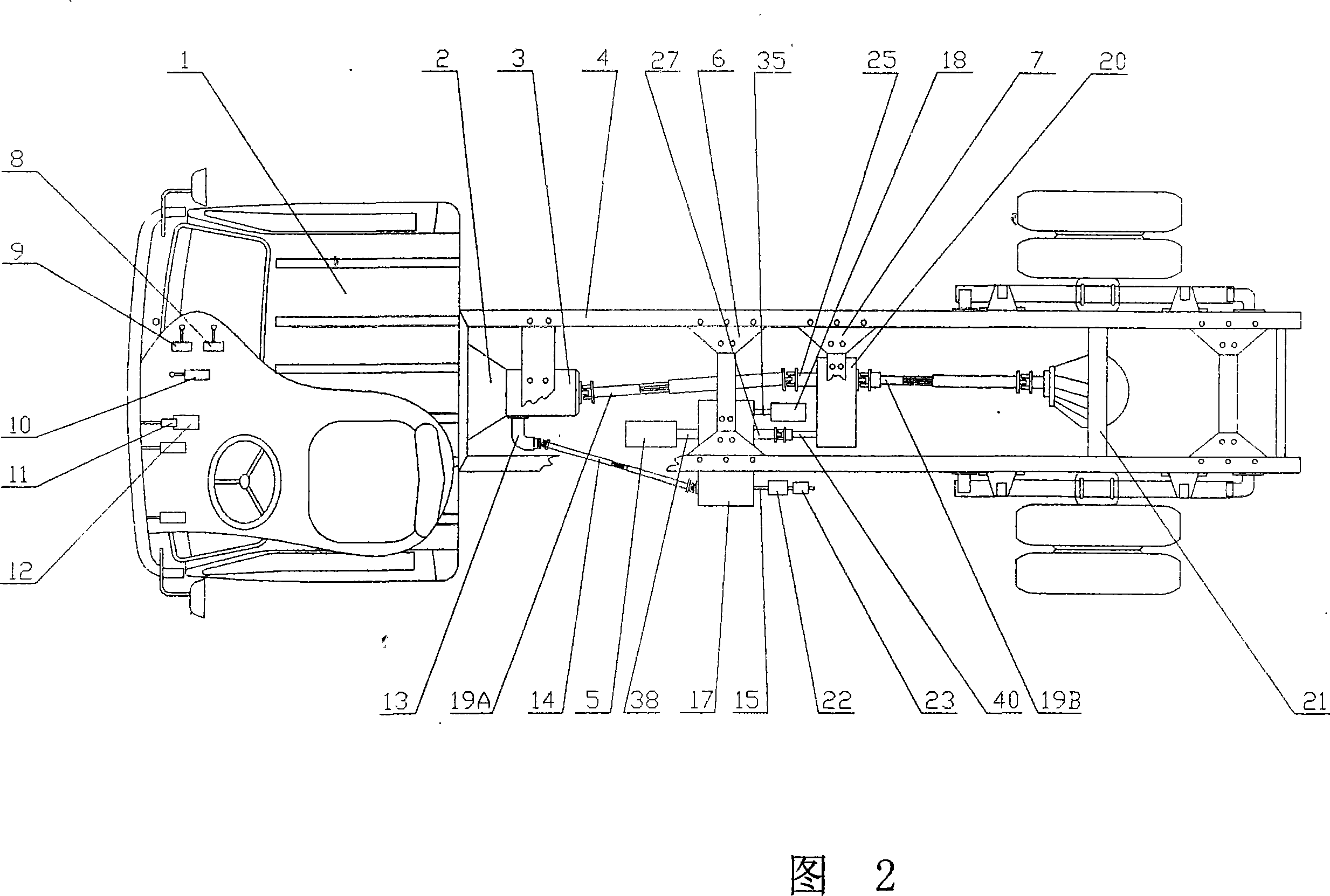

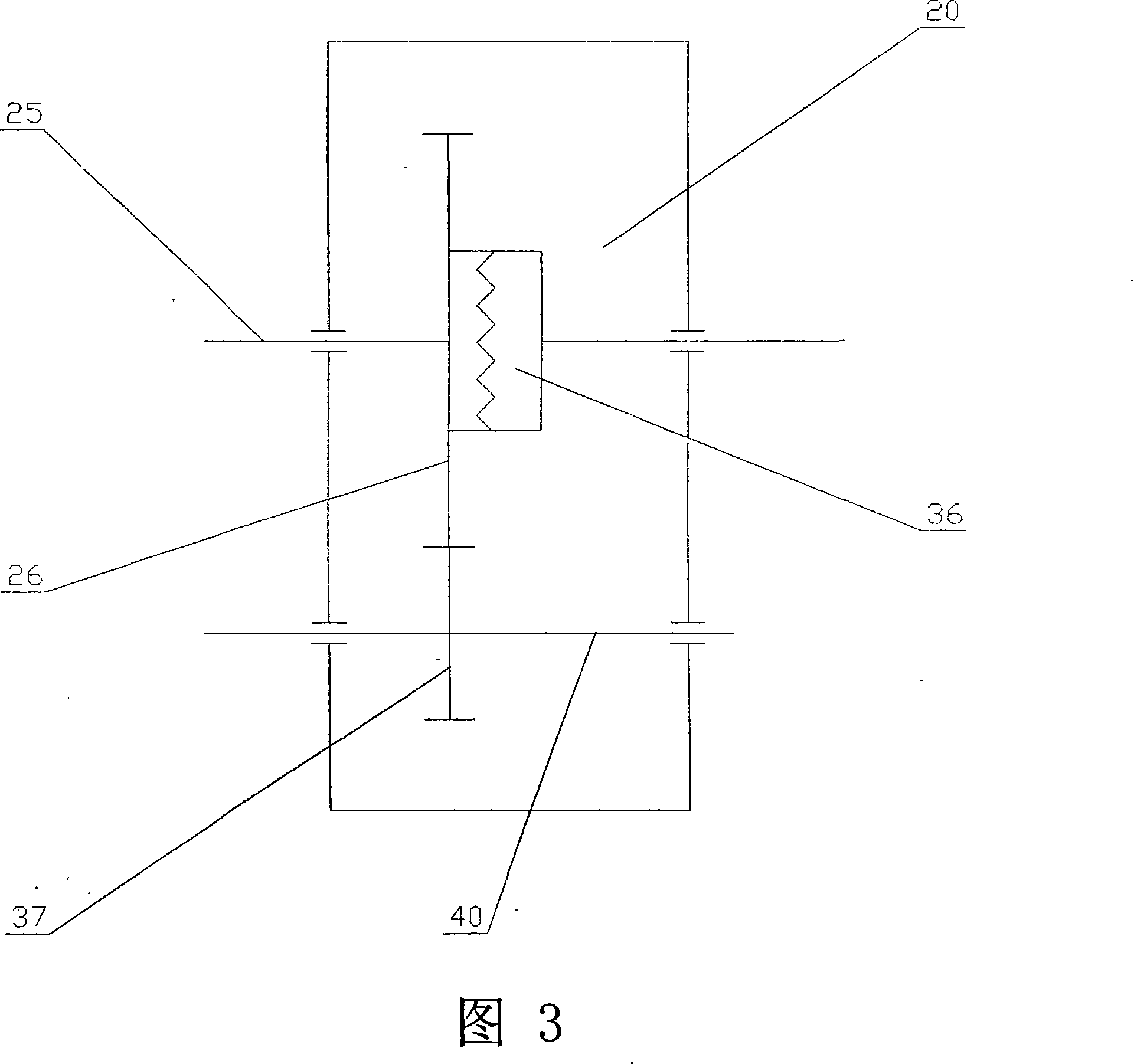

[0062] Fig. 2 is a structural diagram of the second embodiment of the mechanical-hydraulic compound transmission mechanism of the present invention, Fig. 3 is a transmission schematic diagram of the component reduction box structure in the second embodiment, and Fig. 4 is a supplementary schematic diagram of the second embodiment of the present invention.

[0063] As shown in Figure 2 and Figure 3:

[0064] Cab 1, engine 2, speed changer 3, front support 6, rear support 7 are installed on the vehicle frame 4 respectively, and planetary gearbox 17 suspension type is installed under front support 6, and reduction box 20 suspension type is installed under rear support 7. The engine 2 is connected to the transmission 3, and the power take-off 13 is installed on the power take-off interface of the transmission 3. The power take-off 13 has a clutch device connected with the transmission 3 for transmission and separation. The device 13 is connected to the operating handle 8 of the tr...

no. 3 example

[0074] FIG. 5 is a structural diagram of a third embodiment of the present invention, which will be described in detail below in conjunction with FIG. 5 .

[0075] The engine 2 and the front bracket 6 are installed on the vehicle frame 4, and the planetary gearbox 17 is suspended and installed under the front bracket 6; the engine 2 is connected to the transmission front transmission shaft 19A, and the front transmission shaft 19A is connected to the transfer shaft 15 of the transmission planetary gearbox 17 , fixed set transfer gear 16 on the transfer shaft 15, the transfer gear 16 meshes with the transmission transition gear 29; the fluid-passing gear 29 is fixedly connected with the center of the rotating arm 33, and the output end of the rotating arm 33 is vertically and evenly installed with two or three A planetary gear shaft 31, a planetary gear 30 is set on each planetary gear shaft 31, and the planetary gear 30 meshes with the inner teeth of the transmission sun gear 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com