Secondary cooling method and device of high-speed small square billet or small round billet continuous casting machine

A secondary cooling, round billet continuous casting technology, applied in the field of metallurgical continuous casting, can solve the problems of insufficient cooling strength, poor uniformity, bulging deformation, etc., and achieve the effect of solving large bulging deformation, wide market and application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

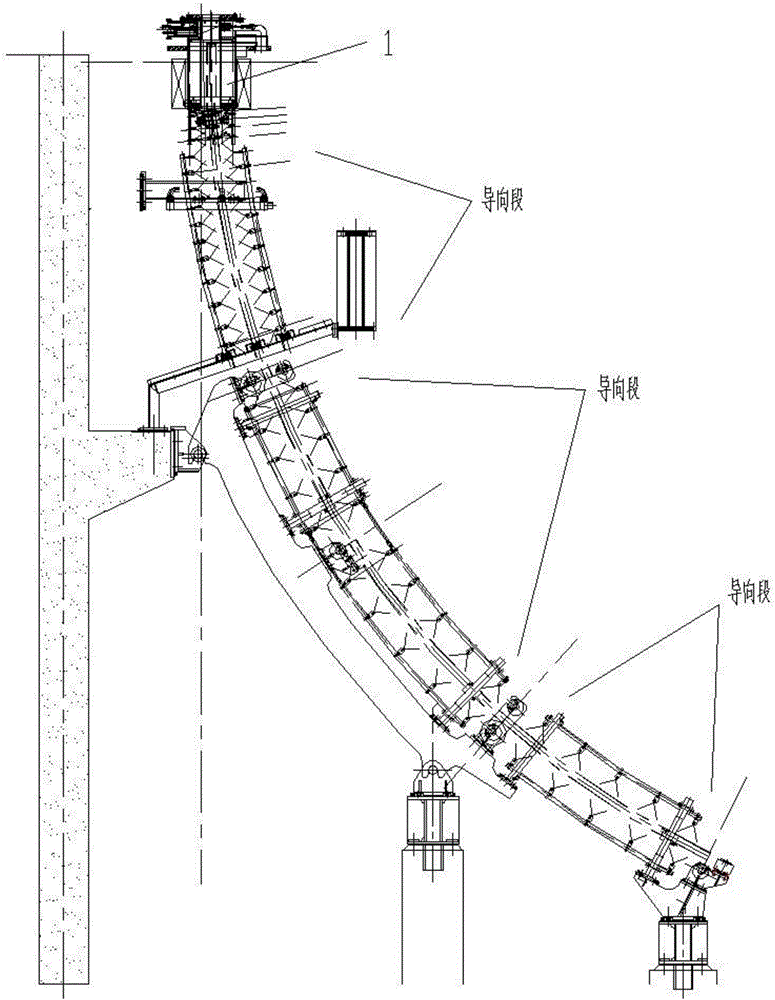

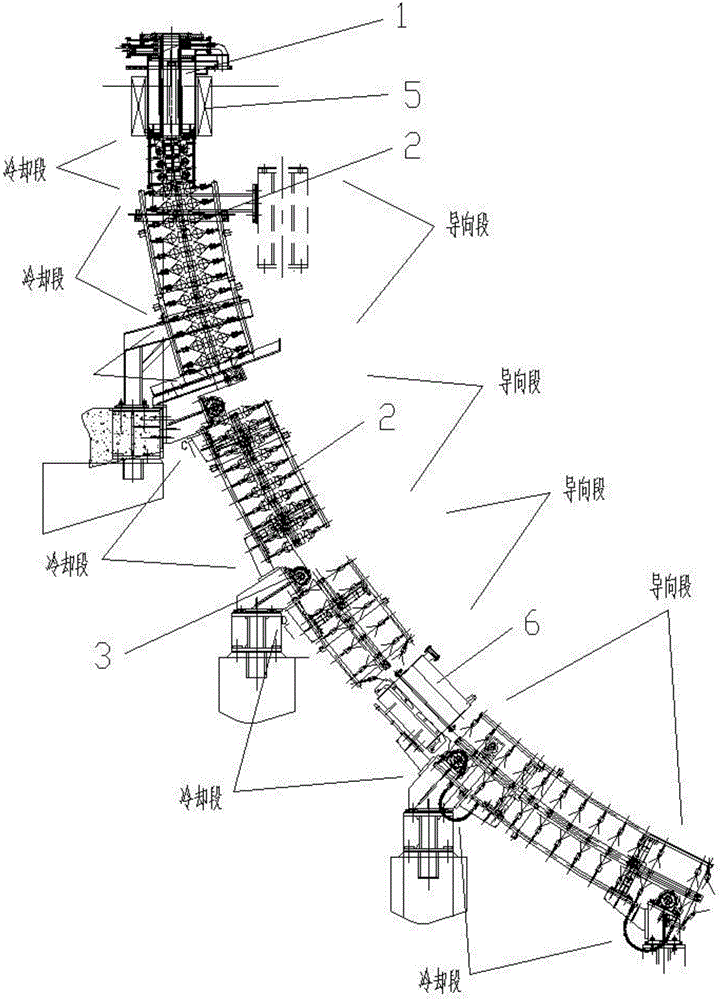

[0024] A secondary cooling method and device for a high-speed billet continuous casting machine. The molten steel is solidified and shrunk in the crystallizer 1 to form a square billet. The inside of the billet is filled with molten steel and the surface forms a thin billet shell, and then enters the secondary cooling zone. The internal molten steel is completely transformed from a liquid state to a solid state to form a solid billet; the cross-sectional specification of the billet is 100-250mm×100-250mm, and the casting speed is controlled at 2.5-8m / min.

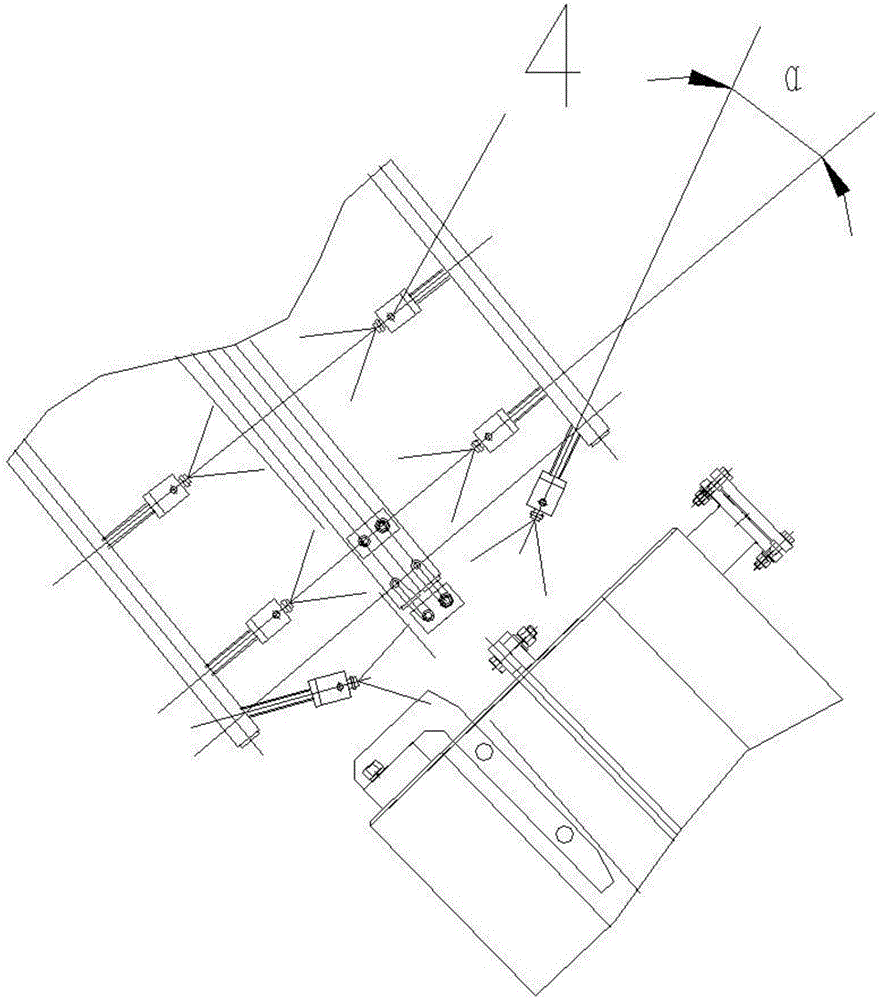

[0025] 1) Divide the secondary cooling zone into four guide sections along the pouring direction to support and guide the slab. The first two guide sections located at the front end and connected to the crystallizer adopt a structure of small roll diameter close-packed rolls 2. The inner arc, outer arc, and left and right sides of the slab are supported and guided to effectively reduce the bulging deformation of the slab, an...

Embodiment 2

[0031] A secondary cooling method and device for a high-speed small round billet continuous casting machine. The molten steel solidifies and shrinks in a crystallizer to form a round casting billet. The inside of the billet is filled with molten steel and the surface forms a thin billet shell. The internal molten steel is completely transformed from liquid to solid to form a solid billet; the cross-sectional specification of the billet is 100-250mm, and the casting speed is controlled at 2.5-8m / min.

[0032] 1) Divide the secondary cooling zone into four guide sections along the pouring direction to support and guide the slab. The first guide section located at the front end and connected to the crystallizer adopts a structure of small roll diameter close-packed rollers to guide the slab. The inner arc, outer arc, and left and right sides are supported and guided to effectively reduce the bulging deformation of the slab, and the remaining three guide sections adopt a single-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com