Fuel cell-based distributed energy system using liquefied natural gas as feedstock

A liquefied natural gas and distributed energy technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as energy waste and cold pollution, achieve high controllability and flexibility, low pollution, and full utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

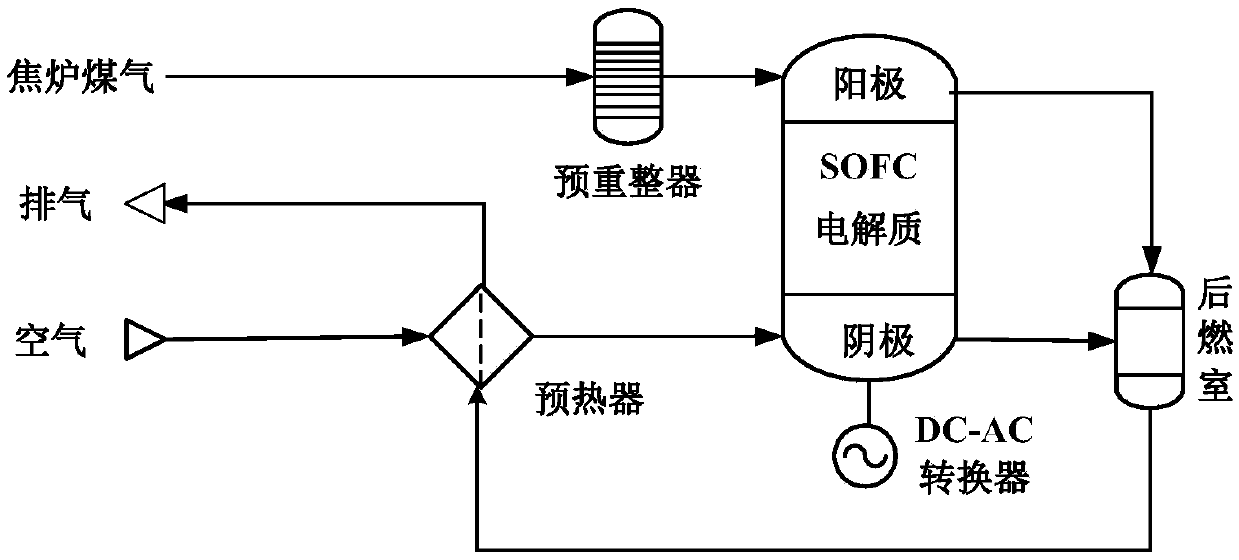

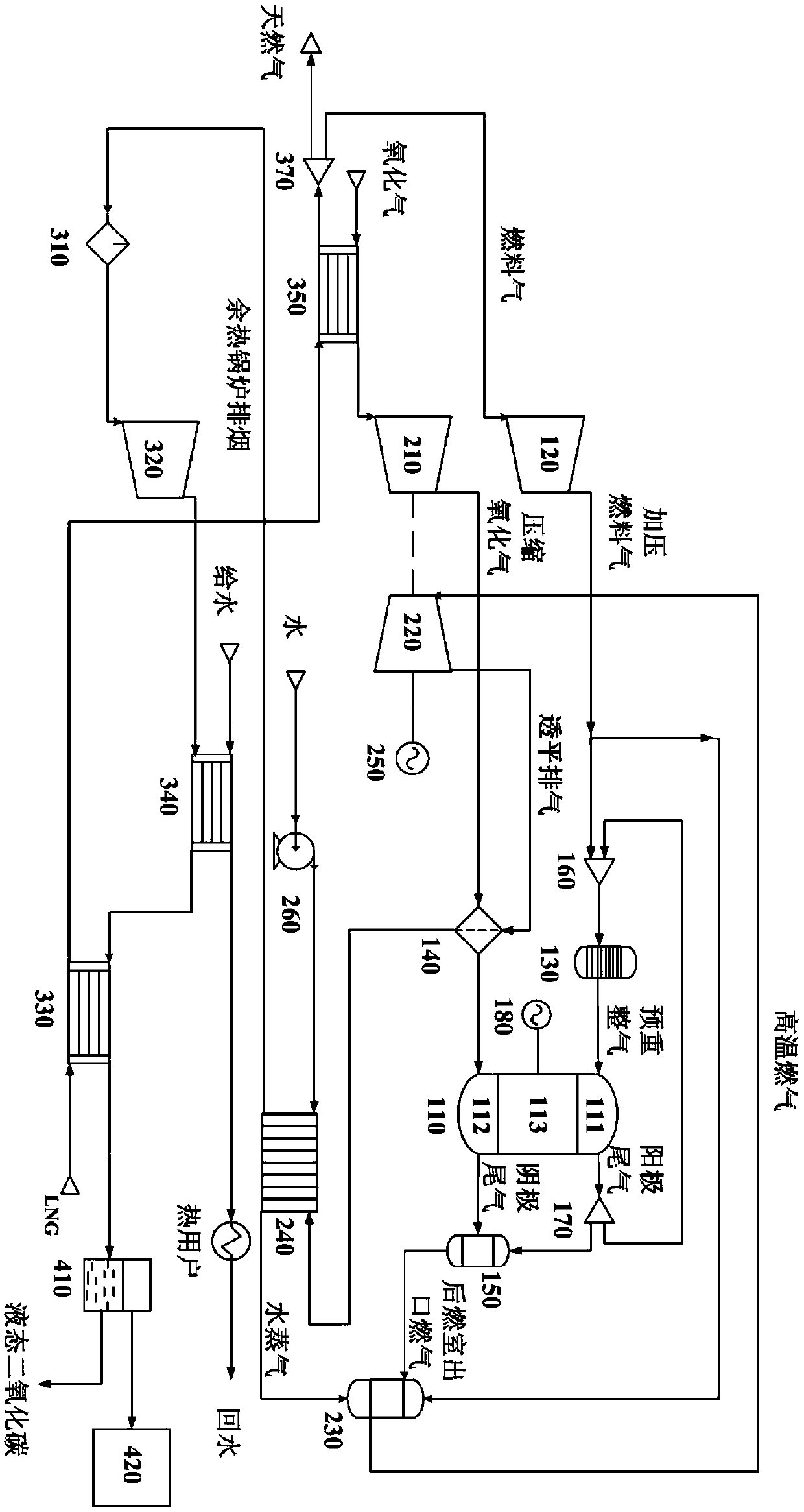

[0071] image 3 It is a schematic structural diagram of a fuel cell-based distributed energy system using liquefied natural gas as a raw material provided by an embodiment of the present invention. Such as image 3 As shown, this embodiment provides a fuel cell-based distributed energy system using liquefied natural gas as a raw material, including a solid oxide fuel cell subsystem, a steam injection gas turbine subsystem, and a liquefied natural gas refrigeration subsystem:

[0072] The solid oxide fuel cell subsystem includes a solid oxide fuel cell stack (not shown), a fuel compressor 120, a pre-reformer 130, a preheater 140, and an afterburner 150. The solid oxide fuel cell stack includes multiple A solid oxide fuel cell 110, the solid oxide fuel cell 110 has a cathode inlet and an anode inlet for oxidizing gas and fuel gas to enter respectively, and a cathode outlet and an anode outlet for respectively discharging cathode tail gas and anode tail gas;

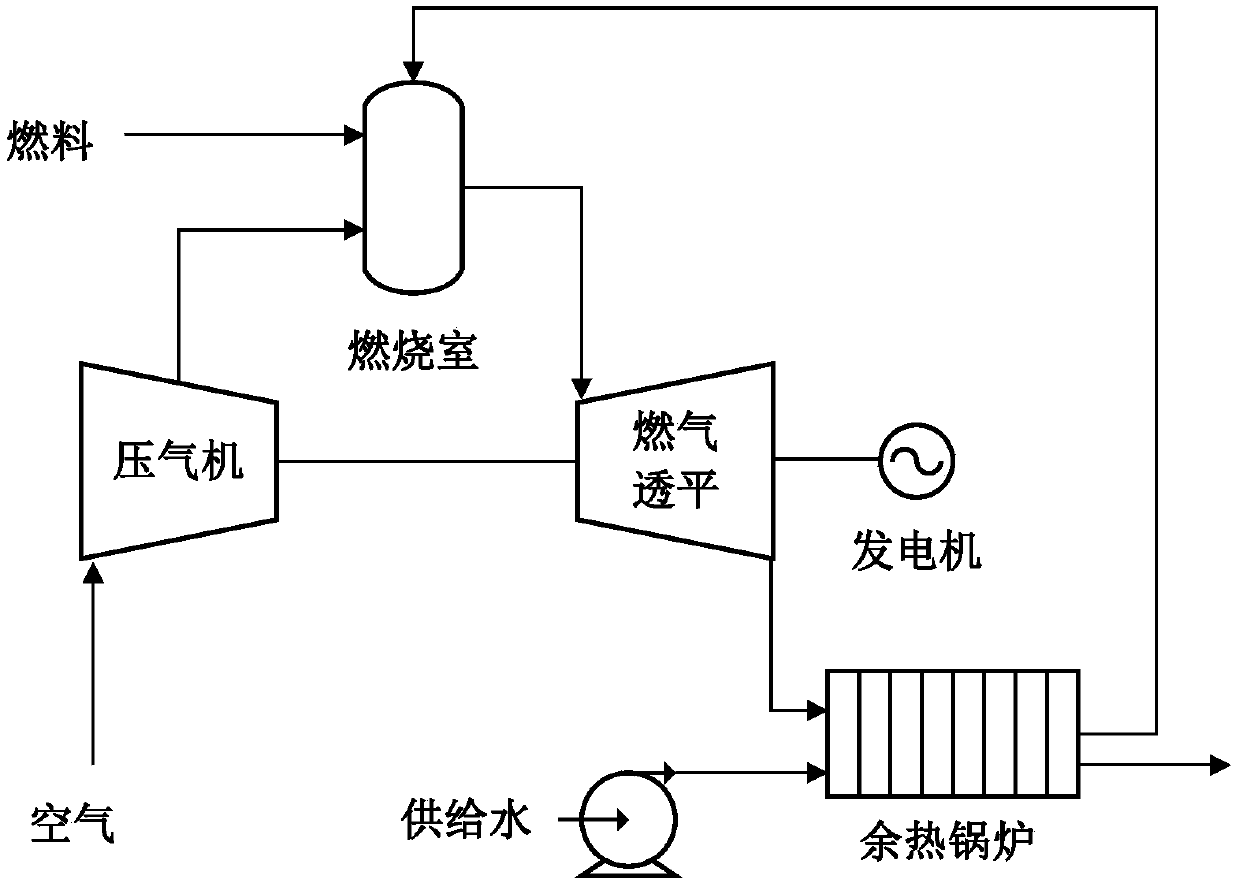

[0073] The steam ...

Embodiment 2

[0115] The distributed energy system in Embodiment 1 is used for energy utilization. The main simulation conditions of the distributed energy system under specific working conditions are shown in Table 1, and the corresponding energy balance table is shown in Table 2; The balance table is shown in Table 3.

[0116] Table 1 Energy system simulation conditions

[0117]

[0118] Table 2 System Energy Balance Table

[0119]

[0120]

[0121] Table 3 System balance sheet

[0122]

[0123]

[0124] According to the calculation results in the above table, under the design conditions, the total electrical efficiency, total thermal efficiency and total The efficiencies were 57.08%, 72.77% and 61.9%, respectively, and liquid CO at a temperature of -69°C and a pressure of 0.3MPa was recovered at the same time 2 The mass flow rate is 12.46kmol / h.

[0125] It can be seen that the SOFC-STIG new distributed energy system using LNG as fuel proposed by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com