Preparation method of P-type heterojunction full-back electrode contact crystalline silicon photovoltaic cell

A full-back electrode contact, photovoltaic cell technology, applied in the field of solar cells, can solve the problems of not having too much space, serious LID light-induced attenuation, etc., and achieve the effect of less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

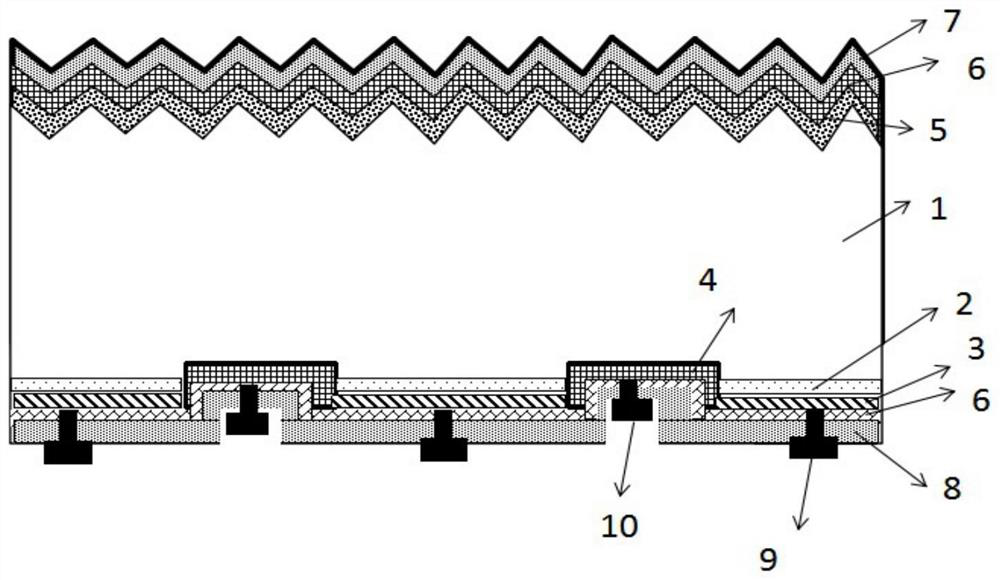

[0028] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] Full back electrode contact crystalline silicon photovoltaic cell (IBC cell) is a technology that moves both the positive and negative metal contacts to the back of the cell, so that the front of the cell facing the sun is completely black, and the front of most photovoltaic cells is completely invisible. metal wire. This not only brings more effective power generation area to users, but also helps to improve power generation efficiency, and the appearance is also more beautiful.

[0030] The present invention makes full use of the existing PERC equipment, and makes it into a P-type heterojunction full back electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com