Ice-cream rod dispersed-rod material-feeding rod-inserting machine

A technology of ice cream and rod insertion, which is applied in the direction of frozen sweets, food science, application, etc. It can solve the problems of ice cream manufacturers increasing costs, difficulty in normal operation of rod insertion machines, production efficiency and waste of source materials, etc., so as to save labor and Packaging costs, cost and waste reduction, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

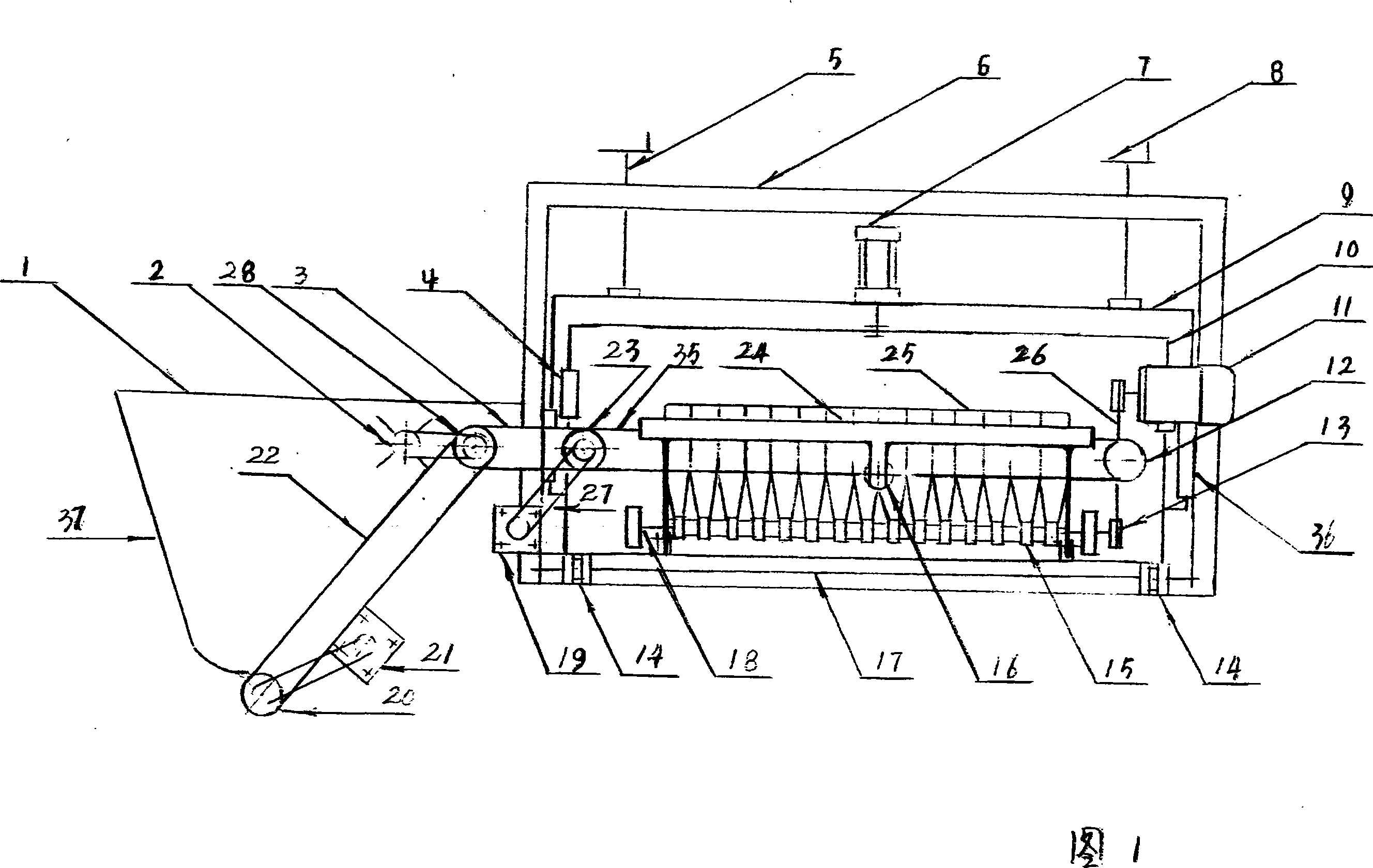

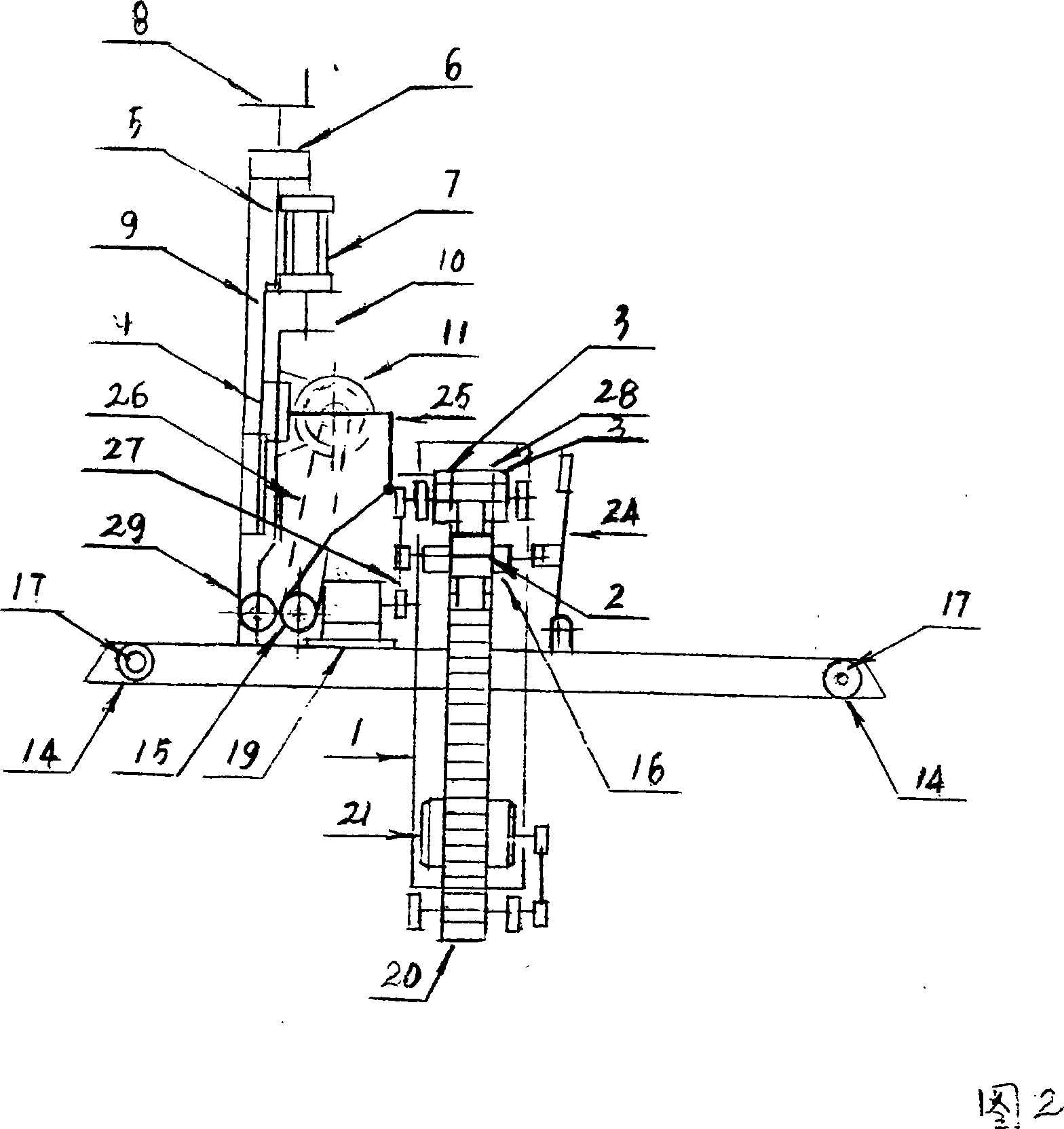

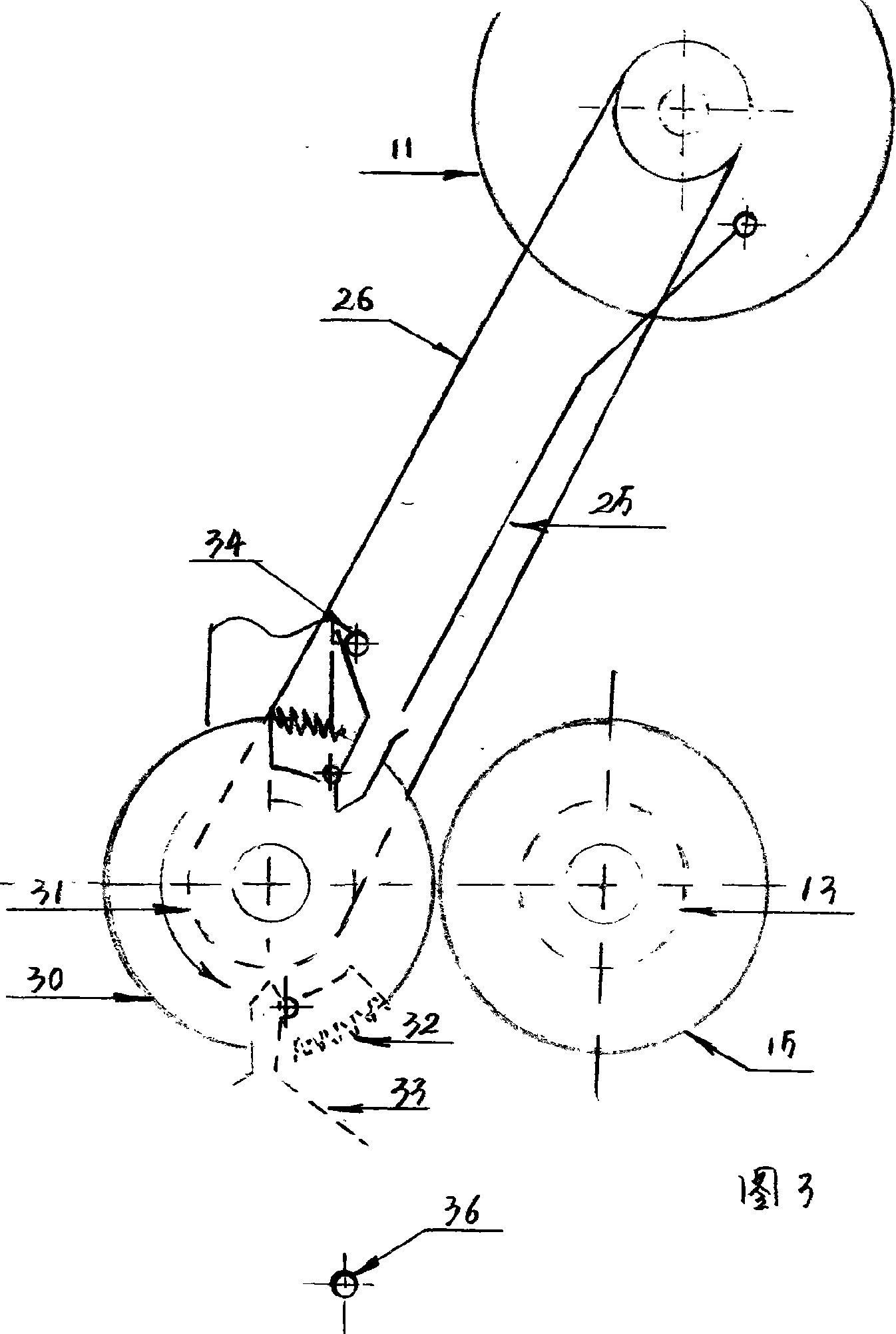

[0024] The specific technical scheme and working process of the present invention will be further described below in conjunction with the embodiments given in the accompanying drawings.

[0025] The parameters of this embodiment are: loose rod feeding, no card machine, no leakage rod insertion, one person operation, power consumption 0.6 degrees / hour, wide range of rod insertion, length can be from 93mm-150mm, width can be from 8mm- 15mm can be replaced.

[0026] As shown in Figure 1: the loose rod loading and inserting machine for this ice cream production line provided by the present invention mainly includes a hopper, a lifting rod chain plate, a synchronous rod distribution belt, a machine frame, a large slide plate, a small pulley Plate, rod row bucket assembly, front and rear roller assembly, racket plate assembly, rod inserting machine support wheel.

[0027] Wherein the hopper 1 is arranged on the workbench at the 6 side ends of the complete machine frame, the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com