Installation for reheating portioned chilled or frozen snack food products

A fast food, reheating technology, applied in electric heating devices, microwave heating, electric/magnetic/electromagnetic heating, etc., can solve the problems of time-consuming, misoperation, and the heating time cannot accurately correspond to the food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The main features of the compact oven in the preferred embodiment will now be described with the aid of the accompanying drawings. The modes of operation of some components are described in other paragraphs.

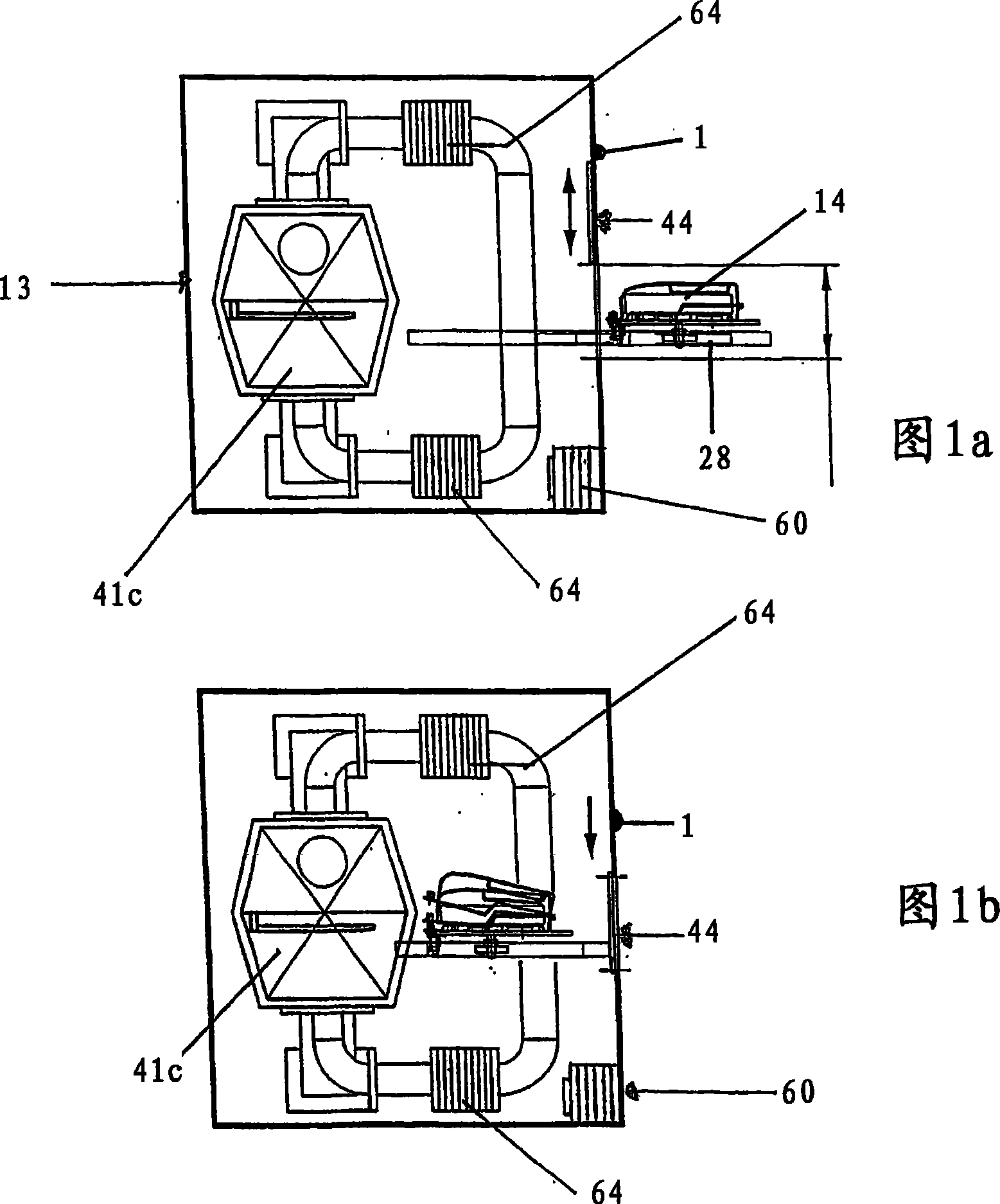

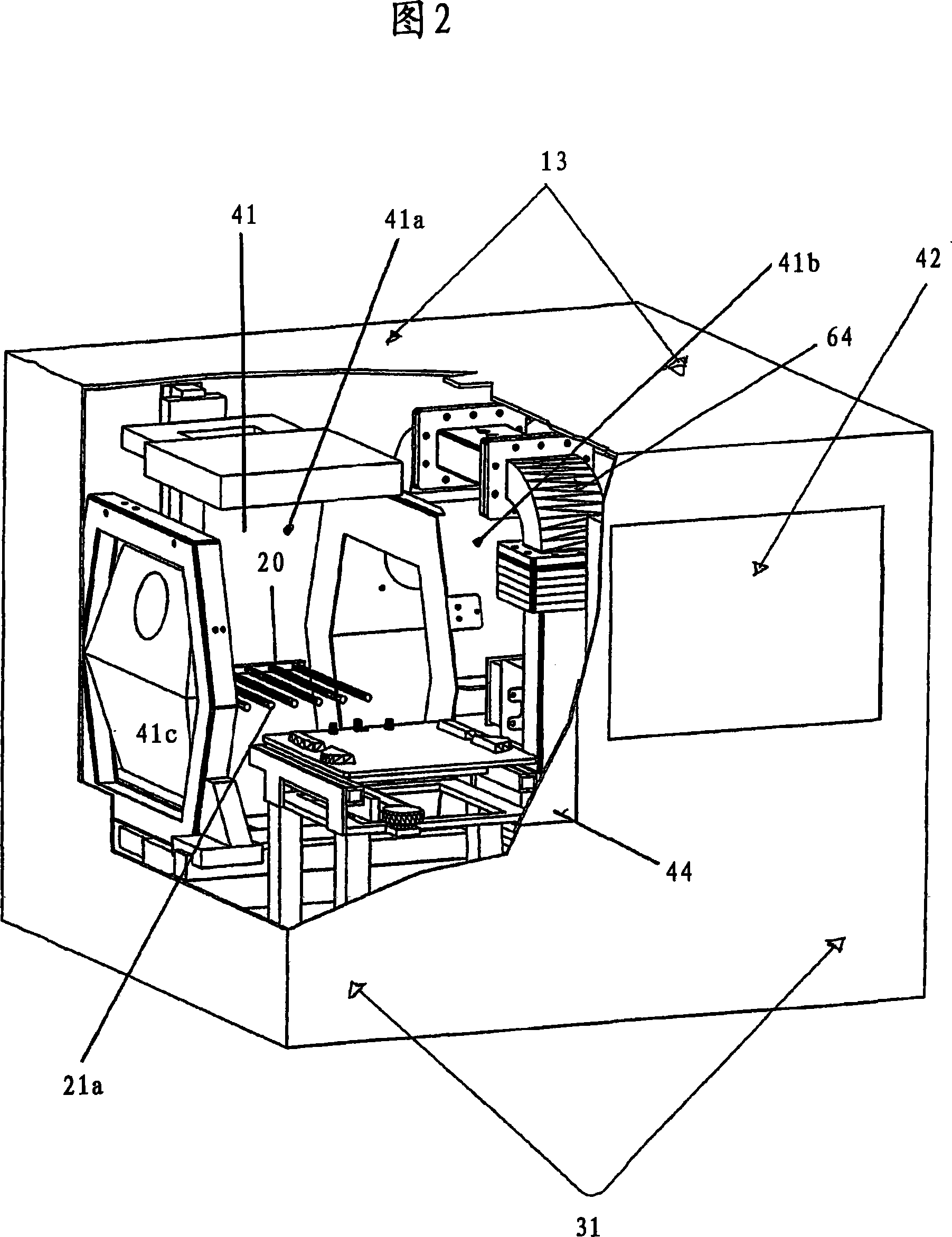

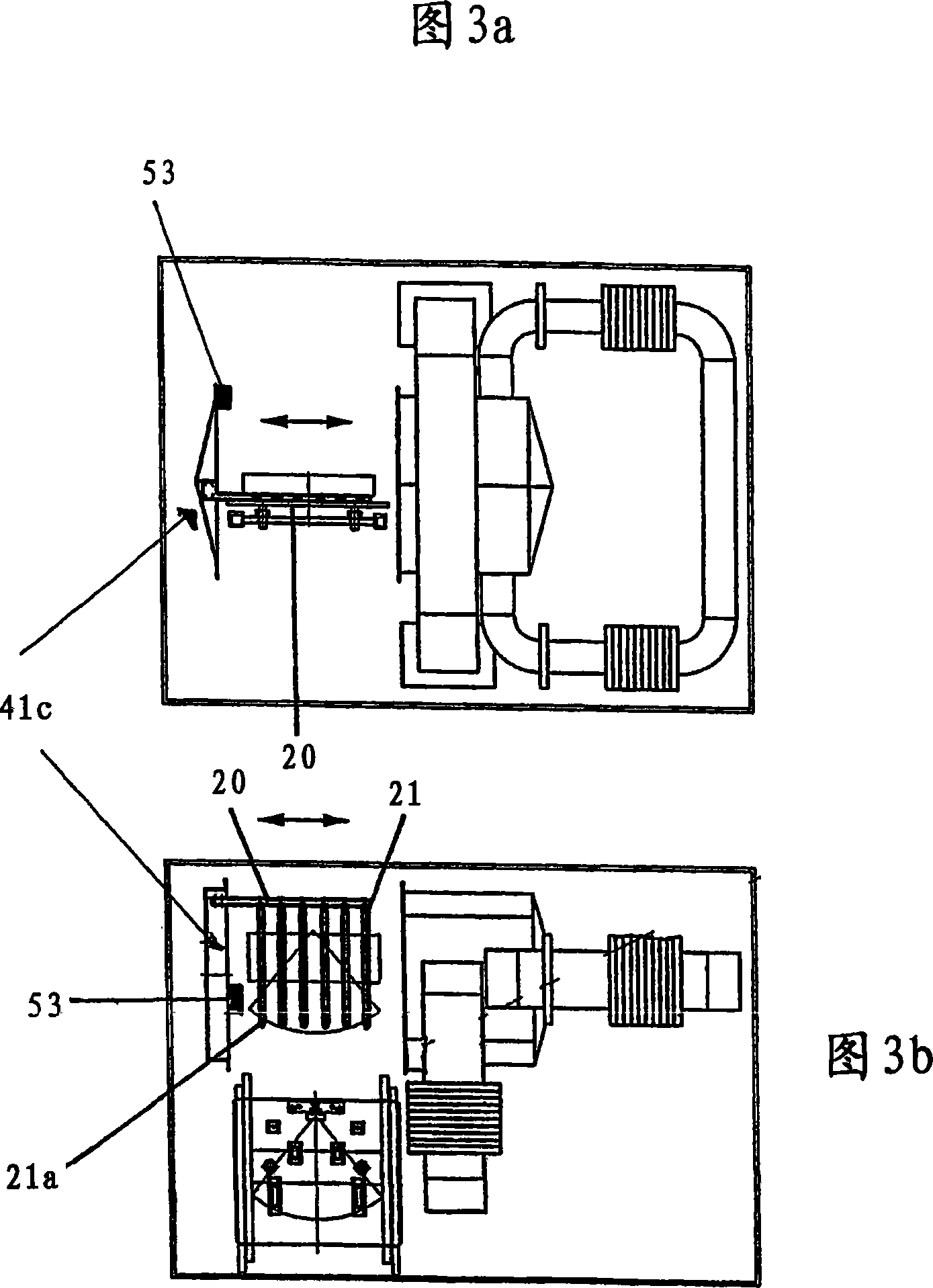

[0034] The compact oven 13 (FIG. 2) comprises a housing 13 with a chamber 41 divided into two chamber areas 41a and 41b (FIG. 4) in which different components are housed. . The CPU device controls the operation of each element of the device and the display screen. The television display screen 42 (FIG. 2) is used to display operating instructions and / or error messages to consumers, and / or provide consumers with learning and entertainment during the waiting period. An infrared sensor 1 ( FIGS. 1 a , 1 b ) controls the opening of the snap-fit door 44 . The front of the oven is made of strong see-through material (PVC or glass). At least 4 but preferably 6 infrared heating tubes are positioned above and below the movable grill / spike 20 . The mini oven is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com