Battery and battery pack with radiating component

A component and battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as safety issues, fire and combustion, and abnormal temperature in the center of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

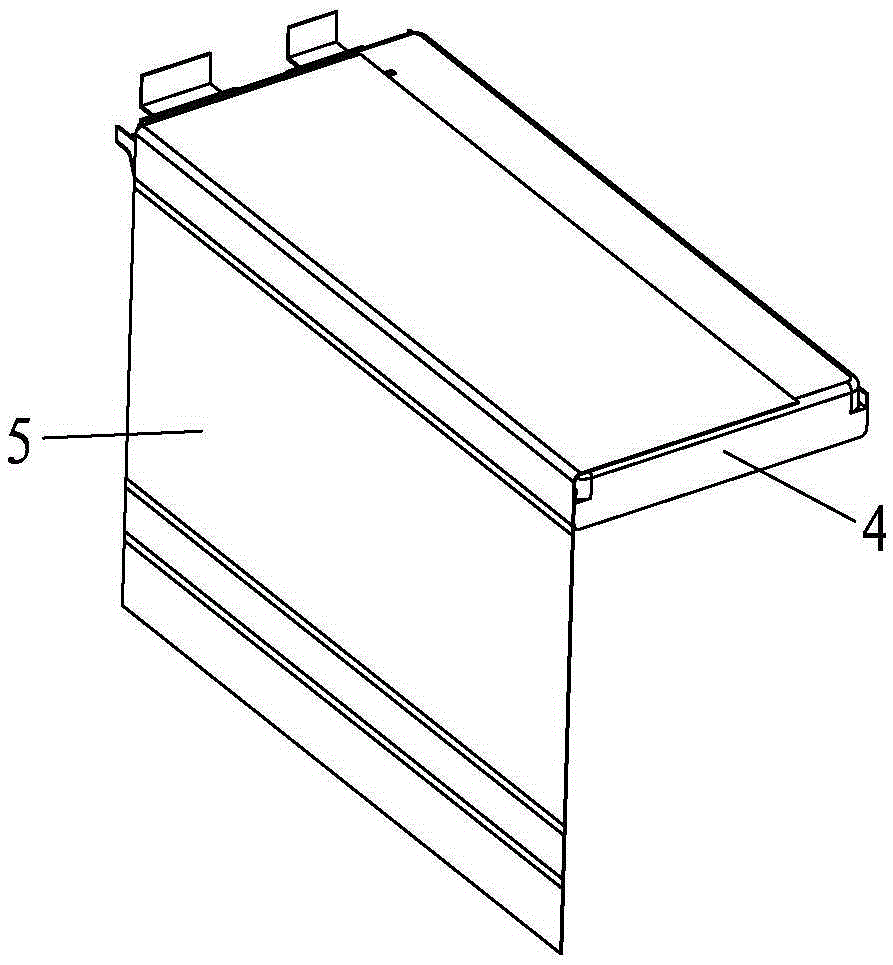

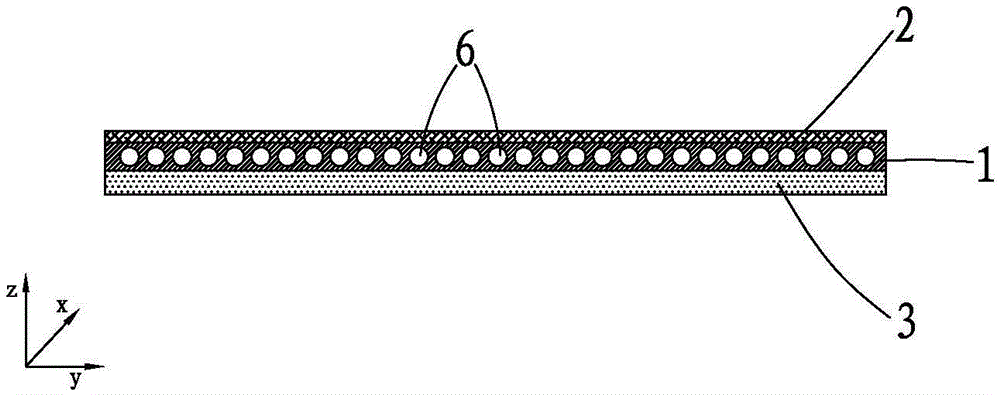

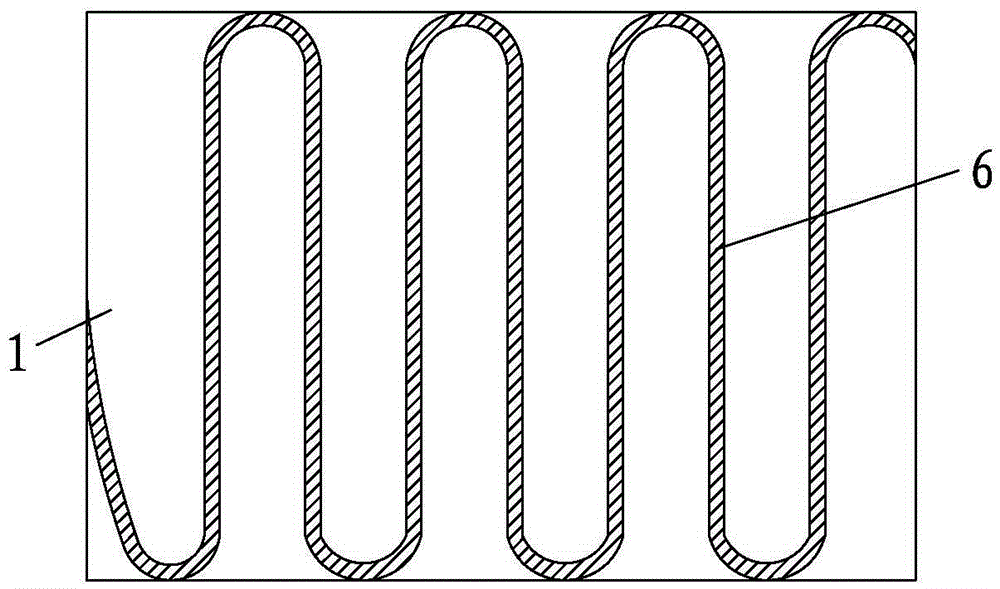

[0034] like Figure 1~3 As shown, a battery with a heat dissipation member includes an electric core 4 and a heat dissipation member 5 coated on the electric core 4. The heat dissipation member 5 includes a separator 1 and a heat dissipation medium, and the separator 1 is provided with a heat dissipation medium (not shown) The flowing channel 6 is coated with a coating (not shown) with wetting properties on the inner wall of the channel 6 . When the battery generates a large amount of heat during charging and discharging, use a separator with good thermal conductivity and a coating with wetting properties (the coating is preferably a nano paint material coating, as long as a stable coating can be formed in theory , At the same time, any coating material that can have good wet contact performance with the heat dissipation medium can be used.) Longitudinal ( figure 2 The direction of the Y-axis) conducts heat longitudinally to the channel and the heat dissipation medium, and t...

Embodiment 2

[0042] like Figure 4 and 5 As shown, the difference from Example 1 is that the heat dissipation layer 2 of this embodiment is coated on one side of the separator 1 by means of intermittent coating, and both the heat dissipation layer 2 and the separator 1 are coated with heat-conducting double-sided The adhesive layer 3 improves the longitudinal conduction function when used in the battery to generate heat.

[0043] In addition, the channel 6 is arranged in an "O" shape in the partition 1, and the heat dissipation medium in the channel 6 is liquid water; the material of the partition 1 is silica gel with a thickness of 10 μm.

[0044] Others are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0046] like Image 6 and 7 As shown, the difference from Example 1 is that the heat dissipation layer 2 of this embodiment is coated on both sides of the separator 1, and the heat dissipation layer 2 is coated on both sides of the separator 1 in a continuous pattern coating method, and A thermally conductive double-sided adhesive layer 3 is bonded to one of the heat dissipation layers 2 . Compared with Example 1, such a structure increases the heat dissipation capacity and improves the working stability of the structure applied in the battery.

[0047] In addition, the channel 6 is arranged in an "I" shape in the partition 1, and the heat dissipation medium in the channel 6 is propylene glycol; the material of the partition 1 is activated carbon with a thickness of 10 μm.

[0048] Others are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com