Tight coupling type gas exhaust system assembly

An exhaust system, tightly coupled technology, applied in exhaust devices, mufflers, engine components, etc., can solve the problems of reduced exhaust gas temperature and long multi-stage catalyst pipelines, reducing packaging costs, simple and compact structure , the effect of a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

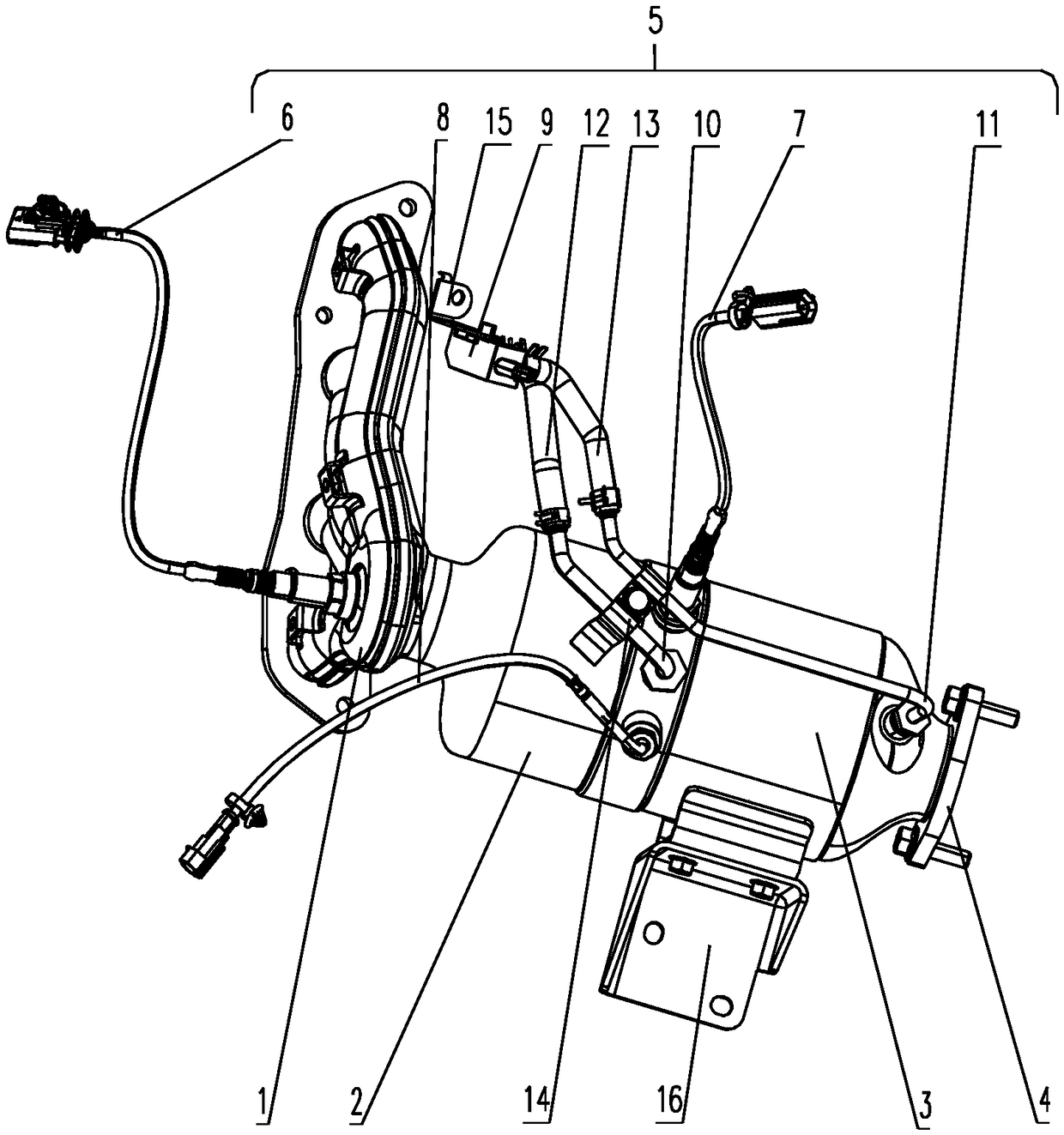

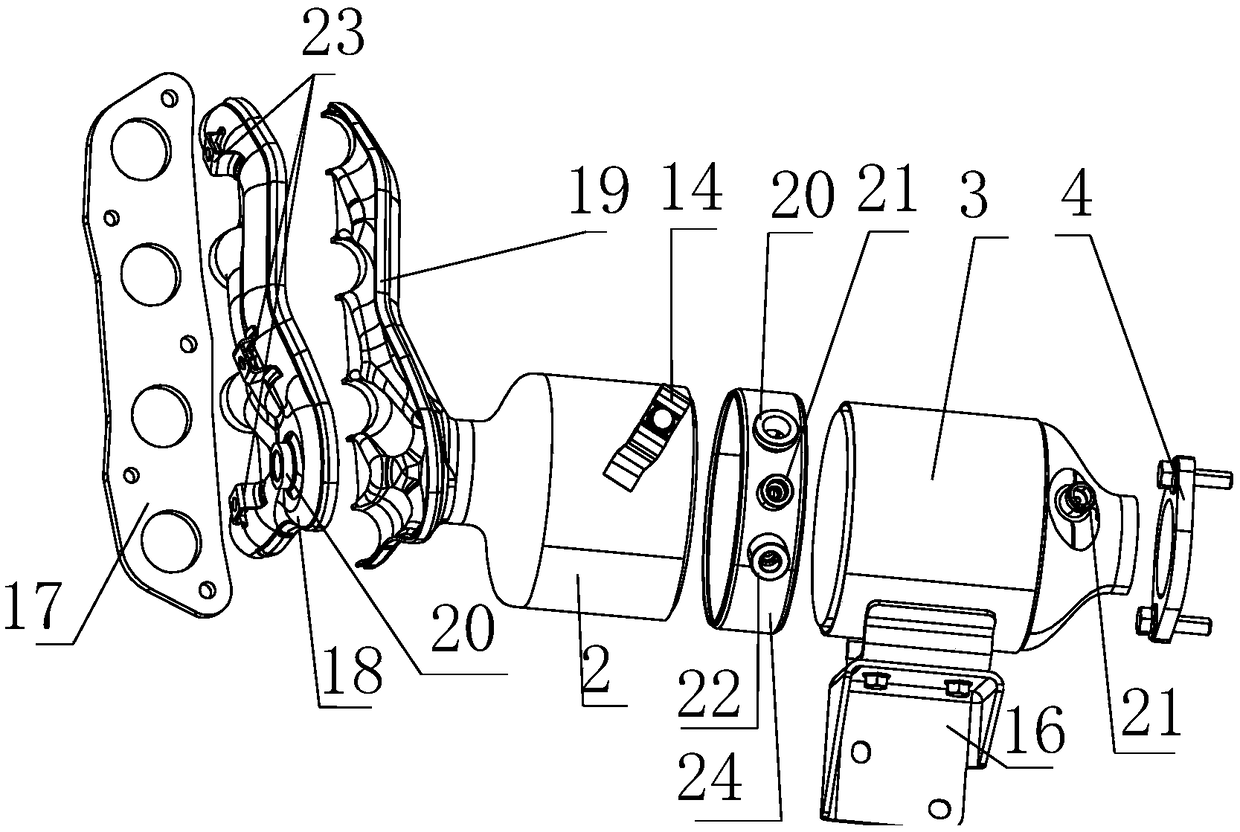

[0027] see Figure 1-Figure 2 . The present invention provides a close-coupled exhaust system assembly, which includes an exhaust manifold assembly 1, a three-way catalytic converter, a particle trap 3 and a connecting cylinder 24; one end of the three-way catalytic converter and the exhaust manifold The component 1 is connected, and the other end of the three-way catalytic converter is connected with the particulate trap 3 through the connecting cylinder 24; the exhaust manifold assembly 1, the three-way catalytic converter and the particulate trap 3 are used to be arranged in the engine compartment. The close-coupled exhaust pipe assembly provided by the present invention, the three-way catalytic converter 2 and the particle trap 3 are connected together to form a cylindrical catalytic purification package, which is beneficial to the rapid light-off of the three-way catalytic converter 2, It solves the problem that the multi-stage catalytic converter pipeline is too long an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com