Prefabricated part assembling frame

A technology of prefabricated parts and picture frames, applied to picture frames, mirrors, household utensils, etc., which can solve the problems of packaging volume, high packaging cost, inconvenient carrying and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

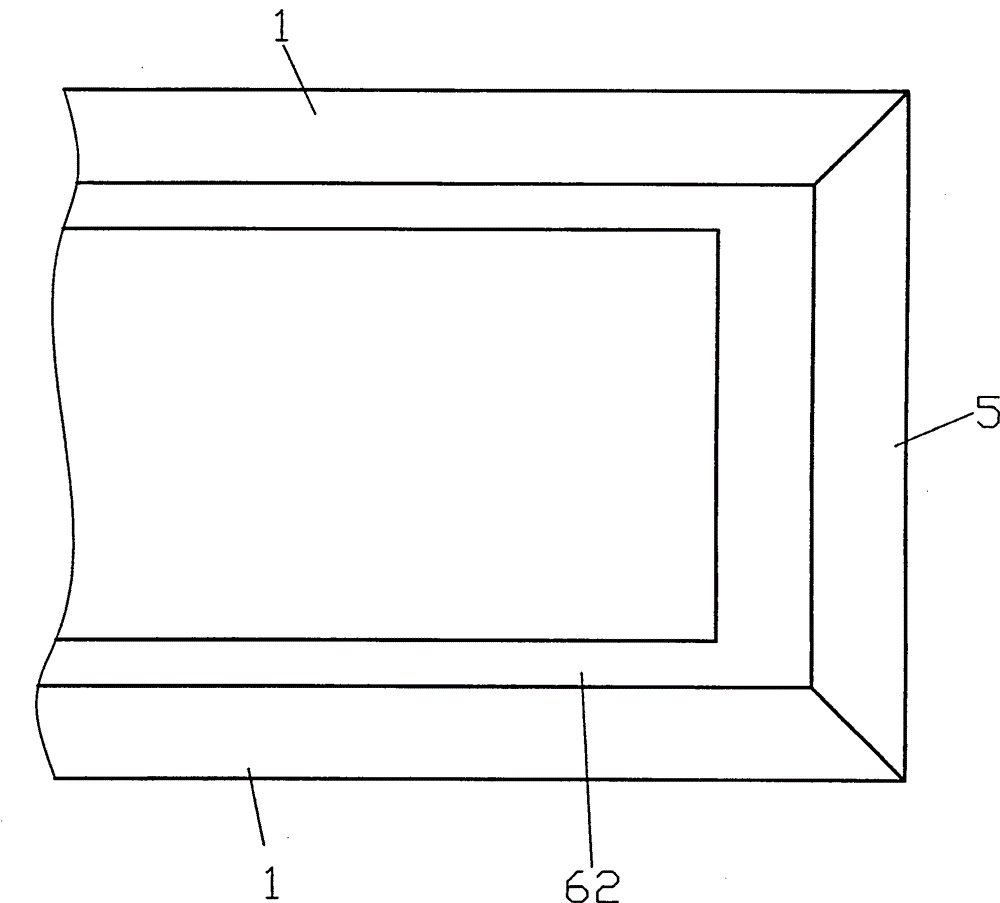

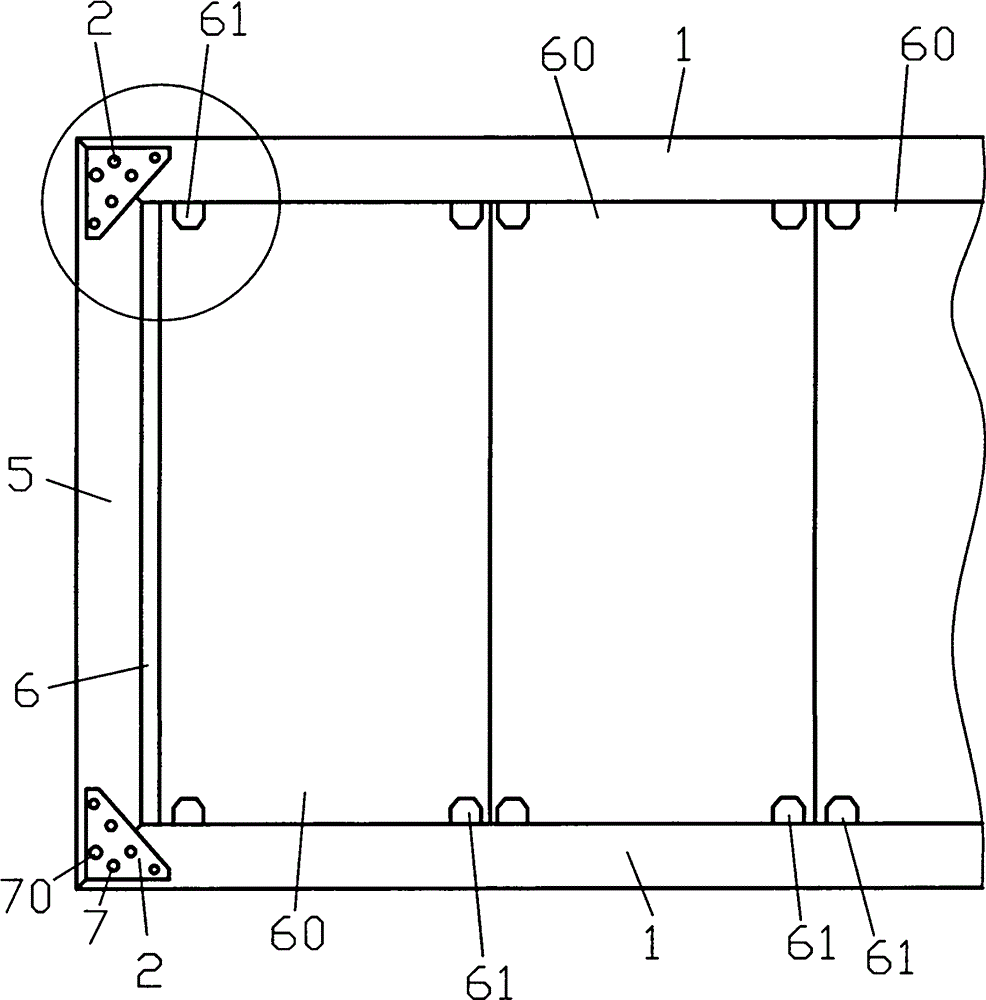

[0061] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the prefabricated picture frame is assembled, and two magnetic block horizontal frames 1 and two magnetic blocks are intercepted and made by prefabricated picture frame parts-magnetic frame strips 23 Mullion 5; connectors - four bolts 3 and bolt base 4; assembly parts - four steel connection angles 2, several wood screws 7, framed picture pieces 62, several backing boards 60 and iron clips 61 with packaging composition;

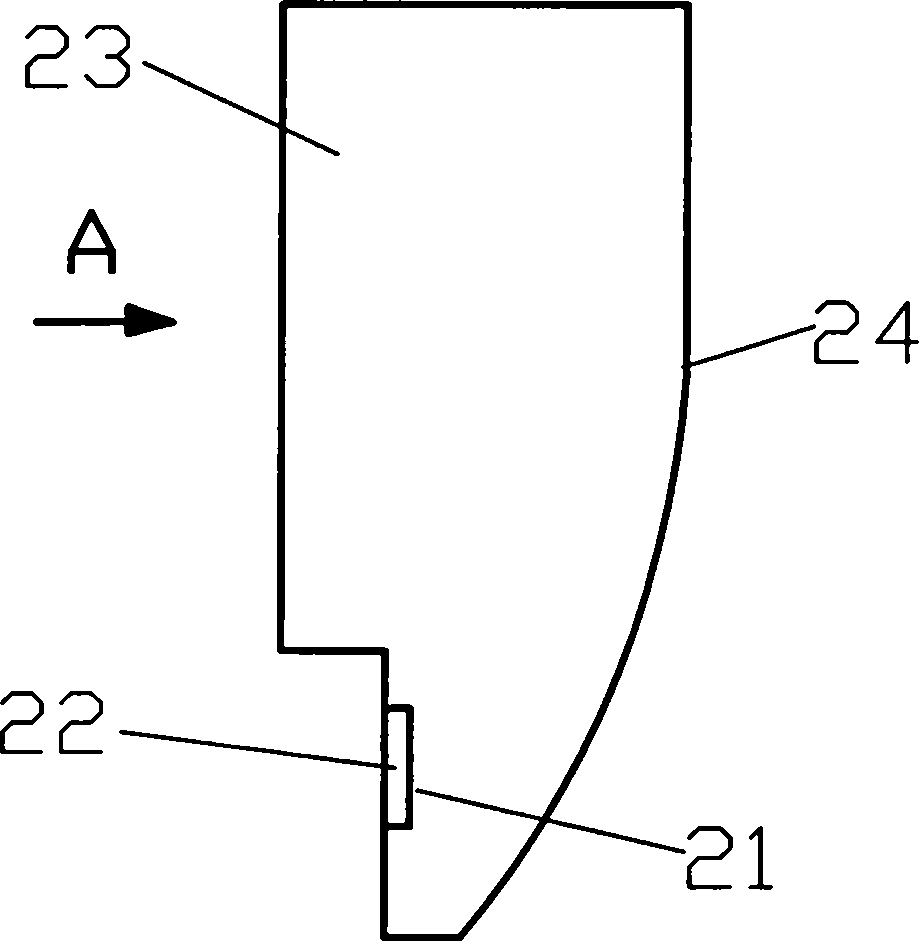

[0062] Such as image 3 , Figure 4 As shown, the lip side of the magnetic frame bar 23 is prefabricated with a magnet groove 21, and several magnet blocks 22 are fixed in the magnet groove 21; into; the four corners of the backing plate 60 are respectively fixed with iron clips 61 (such as figure 2 shown), the iron clip 61 is magnetically coupled with the magnet block 22;

[0063] Such as Figure 5 , Figure 8 As shown, iron clips 61 are respectively fixed in the shaft rods 6 at both ends of the fr...

Embodiment 2

[0067] Such as Figure 9 , Figure 10 Shown: the prefabricated picture frame assembled, two magnetic block horizontal frames 1 and two magnetic block vertical frames 5 made by intercepting the prefabricated picture frame parts - magnetic frame strips 23; connecting parts - four bolts 3 and bolt base column 4; assembly components - four steel connection angles 2, several wood screws 7, framed picture pieces 62, several backing boards 60 and iron clips 61 with packaging;

[0068] The two magnetic block horizontal frames 1 and the two magnetic block vertical frames 5 are prefabricated at both ends of the 45° cutting angle respectively butt joints, and after assembly, a rectangular structural frame is formed, and the four right-angled backs of the rectangular structural frame are cut at 45° At the butt joints of the cutouts, a number of wood screws 7 are used to install and fix the steel connection angle 2 respectively; and then through the connection and fixation of the connecti...

Embodiment 3

[0073] Such as Figure 11 , Figure 12 As shown, one side of the cross section of the prefabricated frame bar 25 is a decorative surface 26, and the specific structure of the decorative surface 26 can be designed into various shapes and patterns according to the needs of the decoration style; 10 and mullion 50, the two ends of horizontal frame 10, mullion 50 are respectively prefabricated as 45 ° cut angle;

[0074] Such as Figure 13 , 14 As shown, the prefabricated picture frame is composed of prefabricated picture frame parts-two horizontal frames 10 and vertical frames 50; connectors-four bolts 3 and bolt base columns 4; assembly parts-four steel Connecting angle 2, several wood screws 7, several backing boards 60 and swivel baffles 9 are packaged together;

[0075] The two horizontal frames 10 and the two vertical frames 50 at the two ends are respectively butted with the prefabricated cut angles of 45°. After assembly, a frame of a rectangular structure is formed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com