Novel barreled wire bonder

A welding wire machine, barreled technology, applied in the direction of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve problems such as affecting product quality, scrapping welding wire, reducing production efficiency, etc., to save packaging and storage costs, The effect of high degree of automation and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

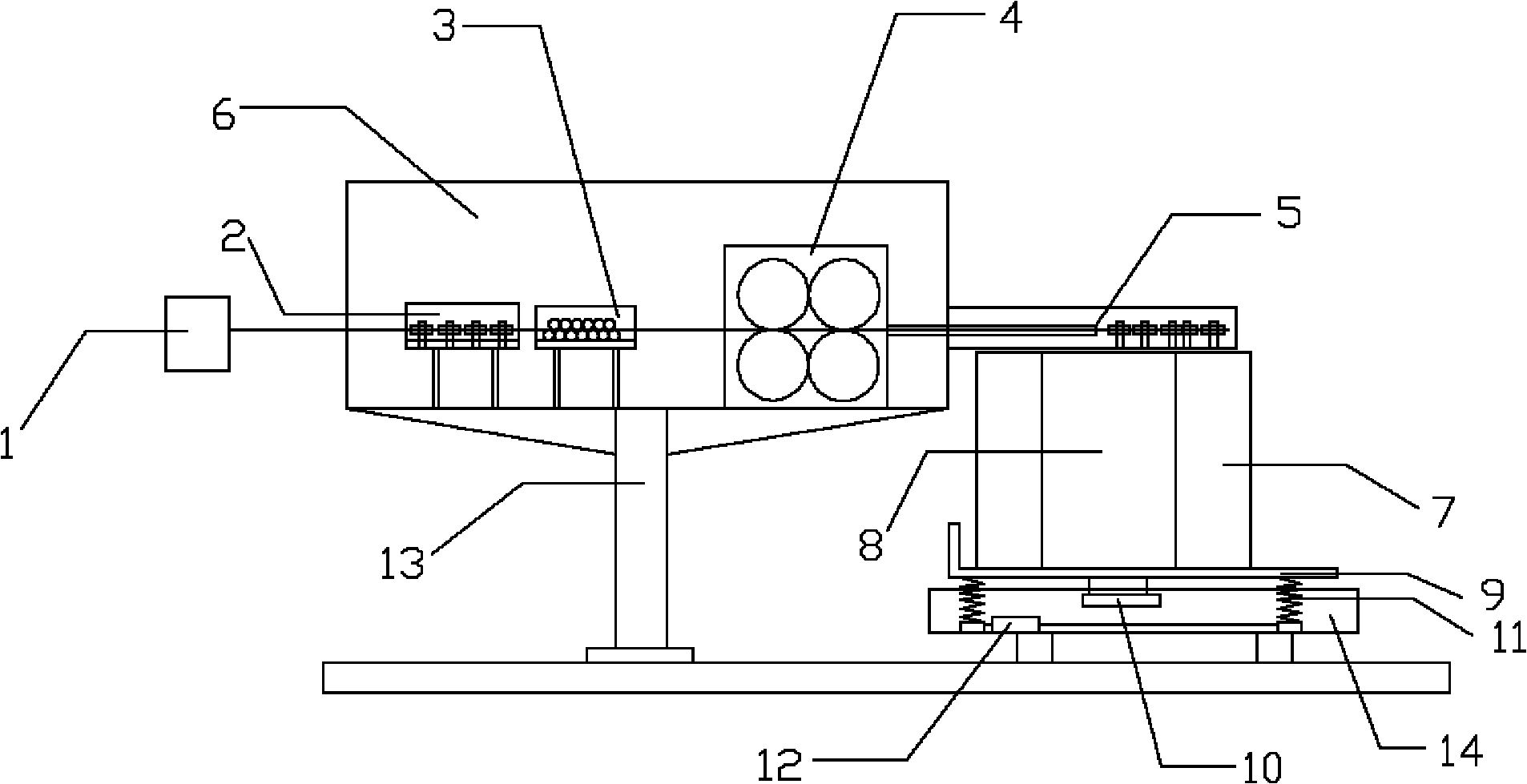

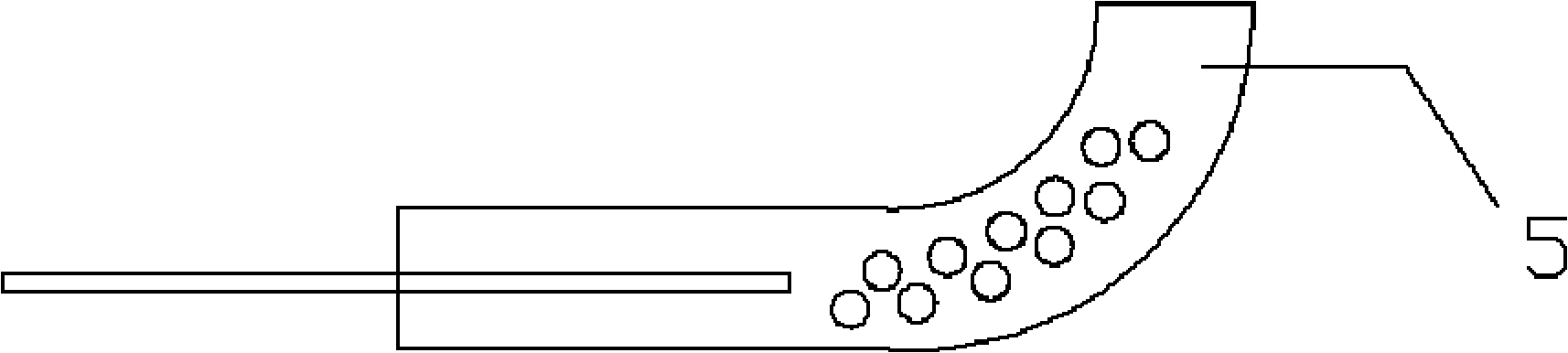

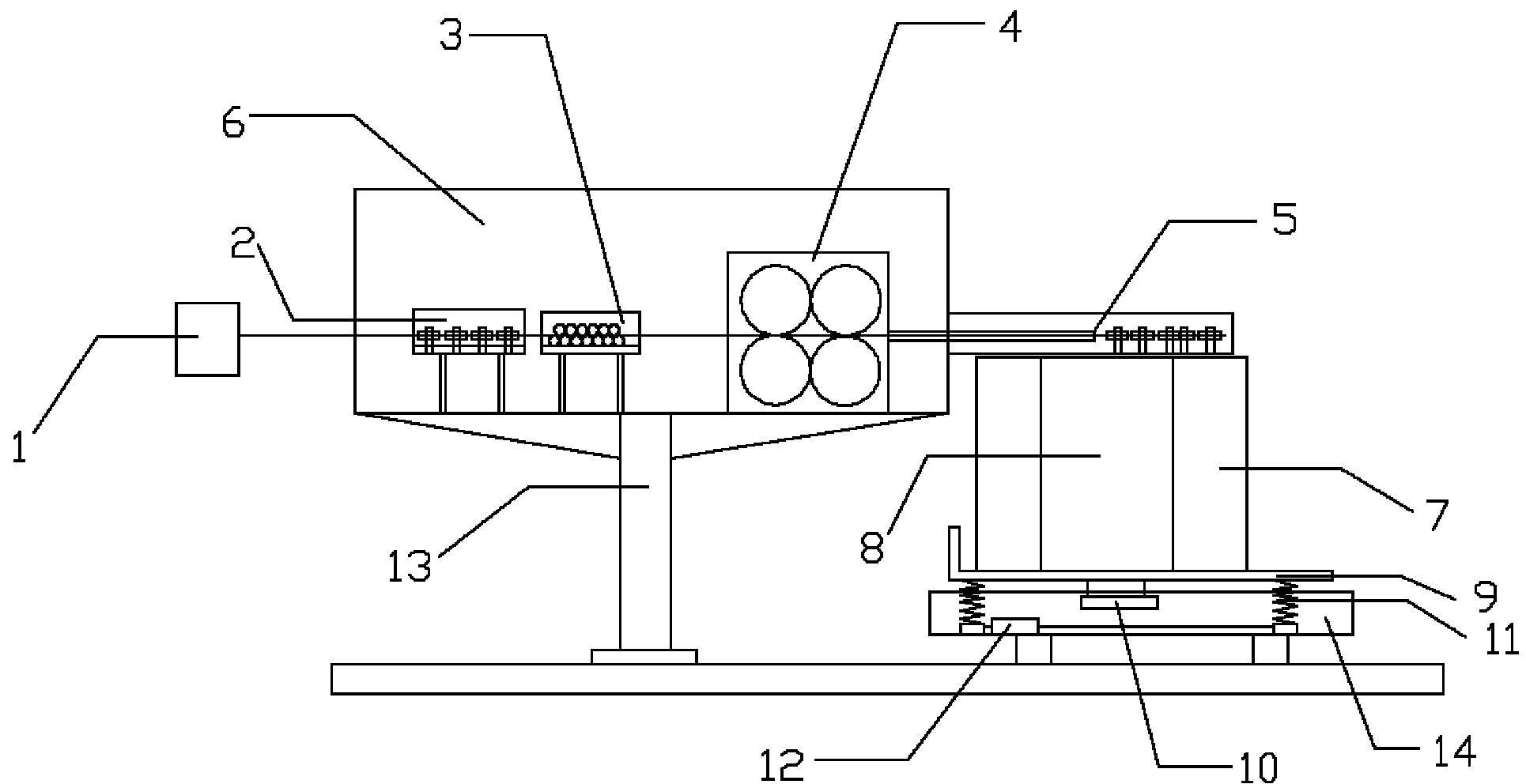

[0023] Such as figure 1 , 2 As shown, a novel barreled welding wire machine of the present invention includes a wire pay-off machine 1, a straightening mechanism, a wire take-up barrel 7, a turntable 9, and a rotating drive mechanism. The straightening mechanism is located in a box body 6, and the box body 6 is placed on a support 13, the pay-off machine 1 is located at the front end of the box body 6, the outlet of the box body 6 outside is provided with a wire guide device 5, the rotation drive mechanism is located in the middle of the bottom support 14 and is connected with the turntable 9 through an eccentric shaft, and the wire take-up barrel 7 It is detachably connected with the turntable 9, the rear end of the straightening mechanism in the box body 6 is provided with a conveying device 4, a barrel core 8 is built in the take-up barrel 7, a vibrator 12 is pressed inside the bottom bracket (14), and the vibrator 12 is connected with the turntable 9 is connected with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com