Rapid manufacturing of porous metal prostheses

a technology of porous metal and prosthesis, which is applied in the field of porous metal prosthesis manufacturing, can solve the problems of high temperature, a significant amount of time, and the need for orthopaedic prosthesis manufacturing to be completed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

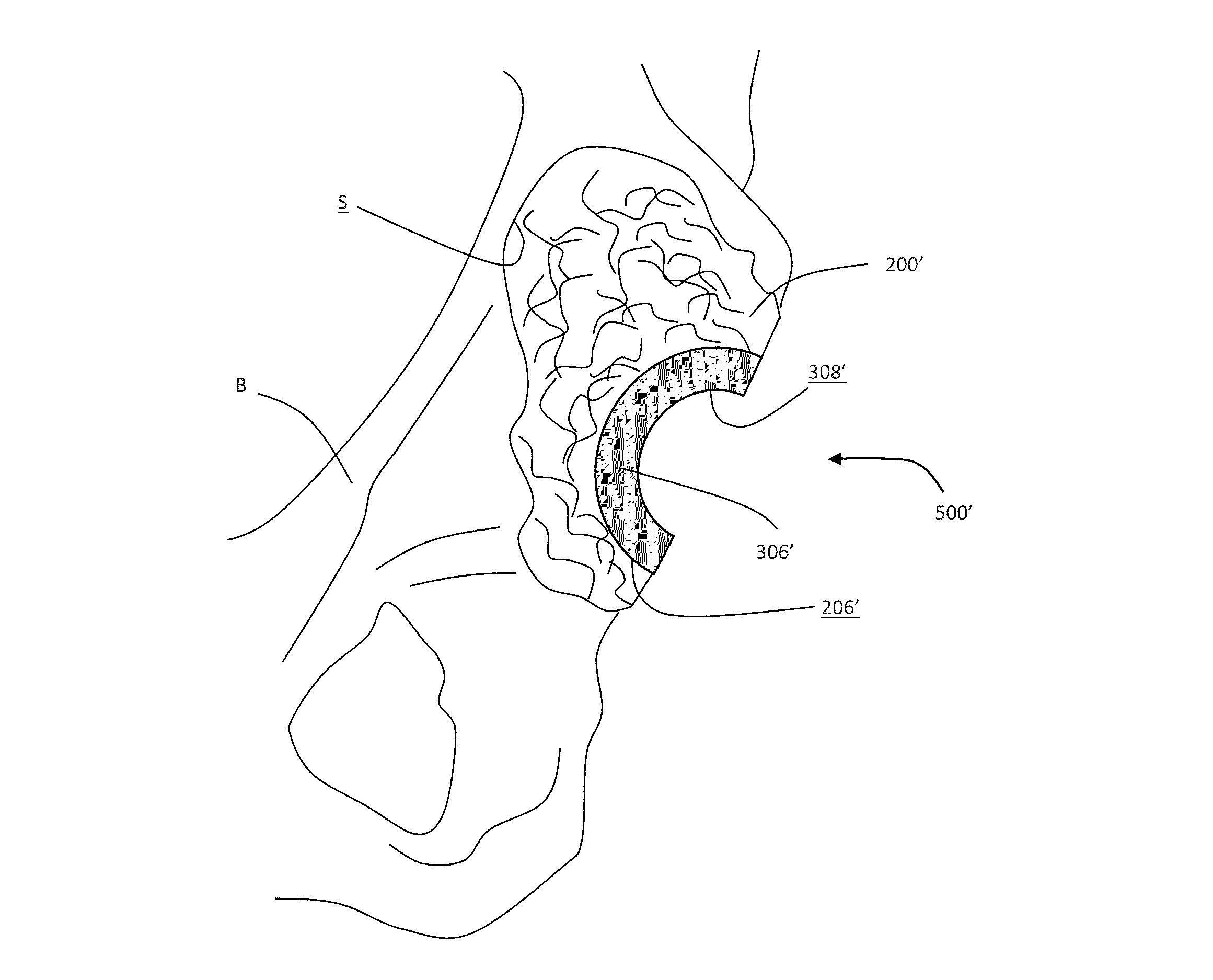

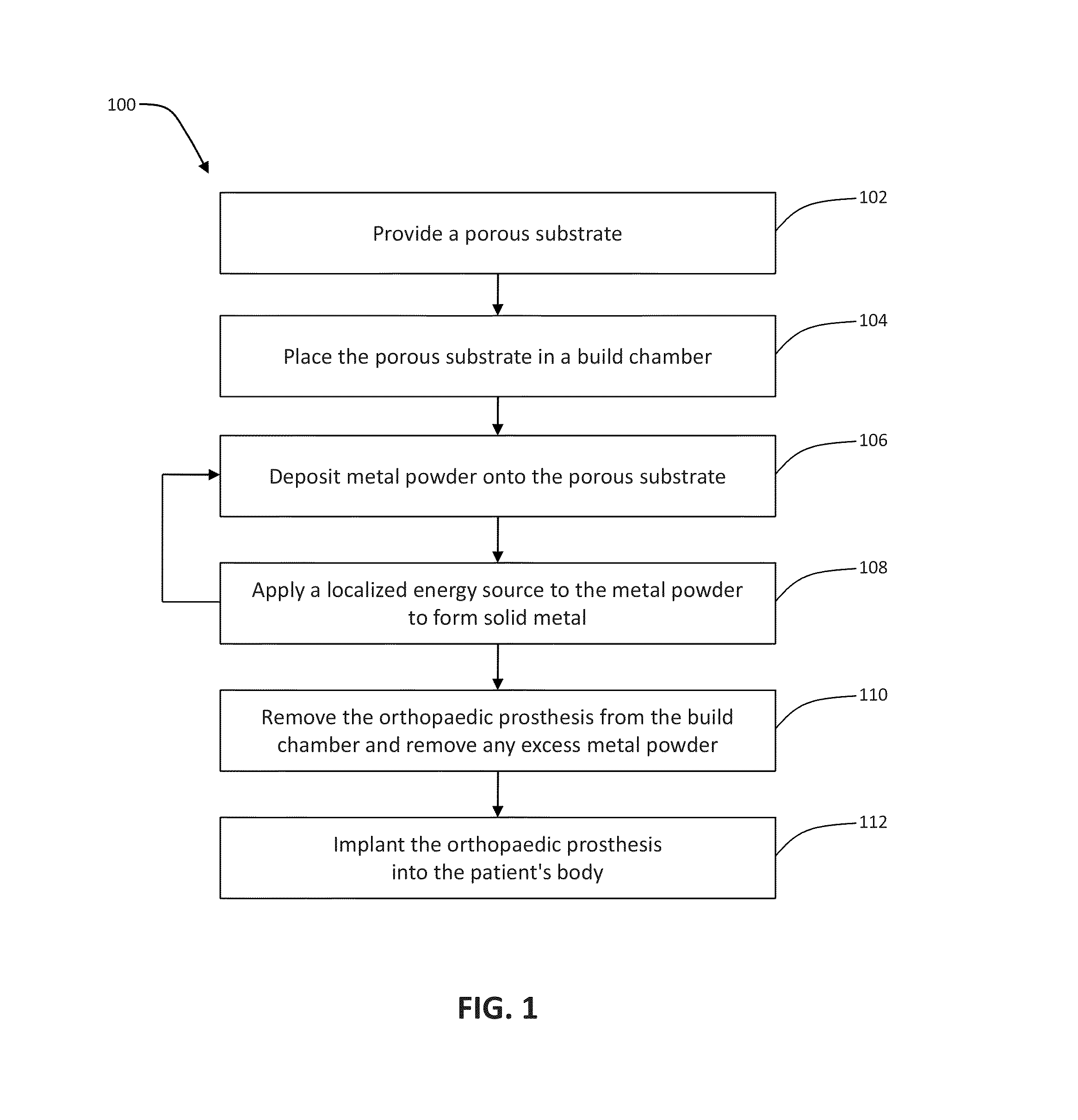

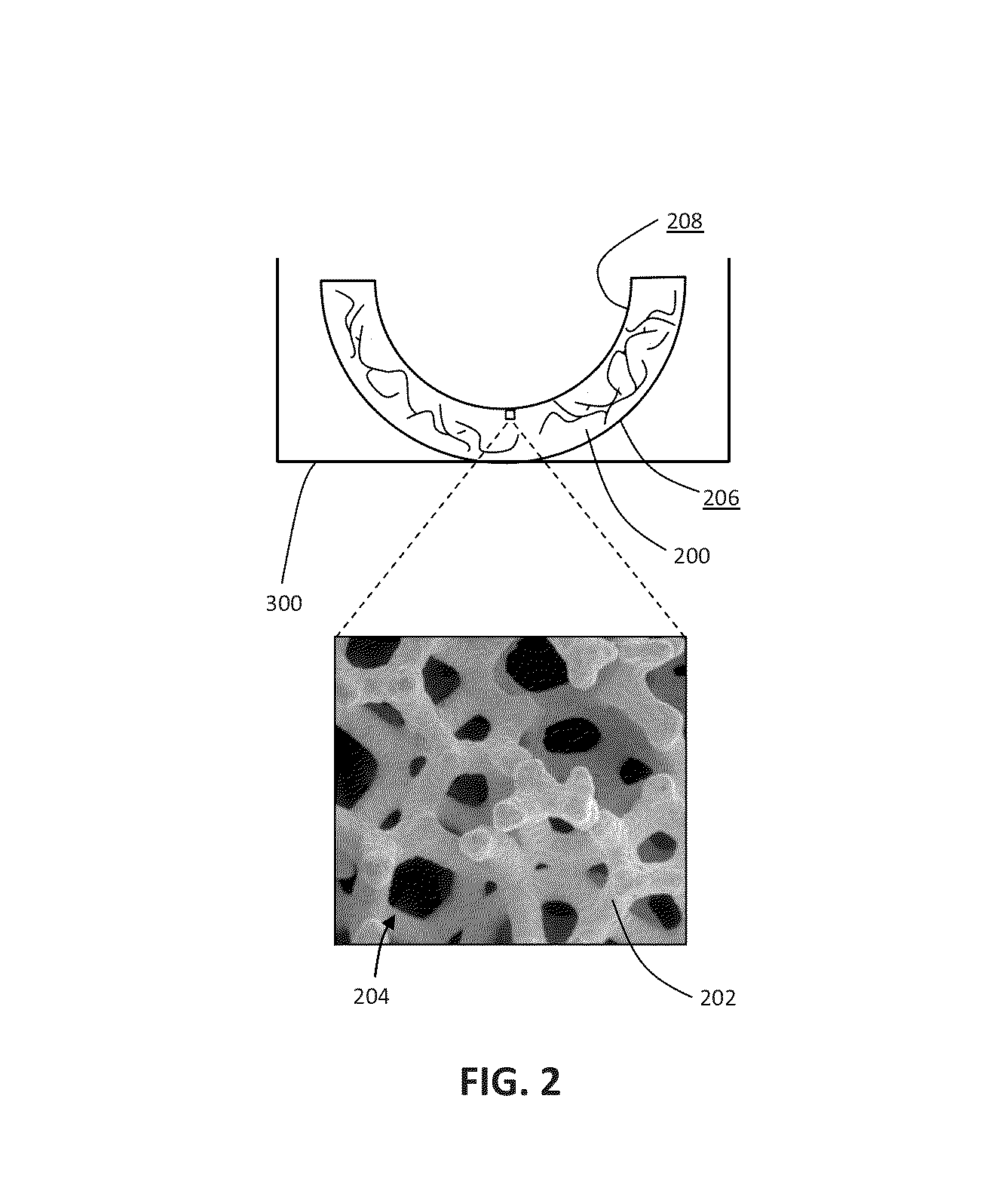

[0023]FIG. 1 provides an exemplary method 100 for designing and manufacturing an orthopaedic prosthesis. Method 100 is exemplified with reference to FIGS. 2-7.

[0024]Beginning at step 102 of method 100 (FIG. 1), a porous substrate 200 is provided having a large plurality of struts or ligaments 202 that define open spaces or pores 204 therebetween, as shown in FIG. 2. Ligaments 202 may be constructed, at least in part, of a first biocompatible metal, such as tantalum, a tantalum alloy, niobium, a niobium alloy, or another suitable metal, for example. In an exemplary porous substrate 200, pores 204 between ligaments 202 form a matrix of continuous channels having no dead ends, such that growth of cancellous bone and / or soft tissue through porous substrate 200 is uninhibited. Thus, porous substrate 200 may provide a matrix into which cancellous bone and / or soft tissue may grow to provide fixation of porous substrate 200 to the patient's bone.

[0025]According to an exemplary embodiment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com