Rapid manufacturing method for sprayed and cured molding sand

A manufacturing method and curing technology, which are used in manufacturing tools, machinery for cleaning/processing of casting materials, casting and other directions. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]Configure molding sand covered with benzenesulfonic acid: use casting silica sand with a particle size of 70-140 mesh as the molding sand, and use a sand mixer or other equipment to mix the molding sand and benzenesulfonic acid at a ratio of 100:1.5, that is, the amount of benzenesulfonic acid added is 1.5% by weight of molding sand.

[0053] Prepare diluted furan resin: Stir and mix furan resin and absolute ethanol using a liquid mixer or other equipment. The weight ratio of furan resin to absolute ethanol is 100:15, that is, absolute ethanol accounts for 15% of the furan resin.

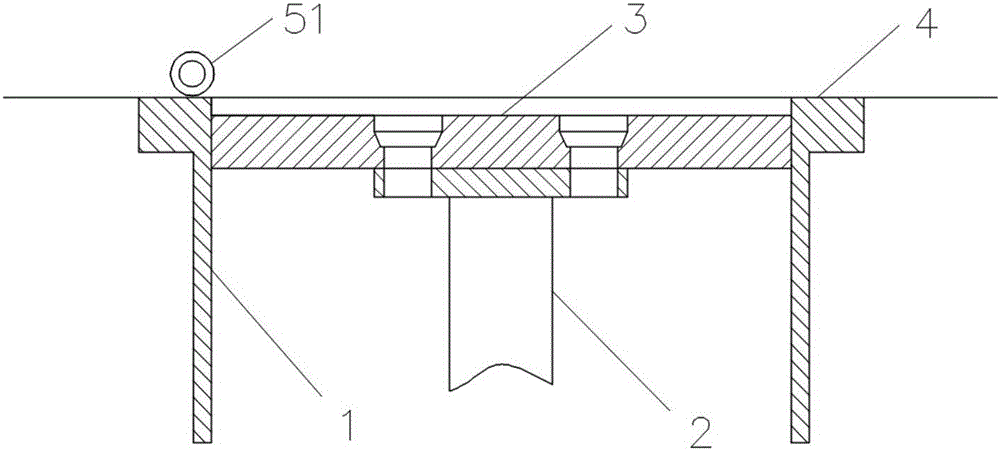

[0054] Rapid manufacturing is achieved by spraying solidified sand, specifically the following steps:

[0055] (a) set up a three-dimensional model of the sand mold in the computer, and carry out layering and data processing on the model; clean up the floating sand on the frame and above of the work surface 4, so that the working area of the molding cylinder 1 range is clean and free of floa...

Embodiment 2

[0062] Configure molding sand covered with p-toluenesulfonic acid: the particle size of the molding sand is 30-50 mesh, use a sand mixer to mix the molding sand and p-toluenesulfonic acid at a ratio of 100:3, that is, the amount of p-toluenesulfonic acid added is the weight of the molding sand 3 %.

[0063] Prepare diluted furan resin: Stir and mix furan resin and isopropanol, the weight ratio of furan resin and isopropanol is 100:20, that is, isopropanol accounts for 20% of furan resin.

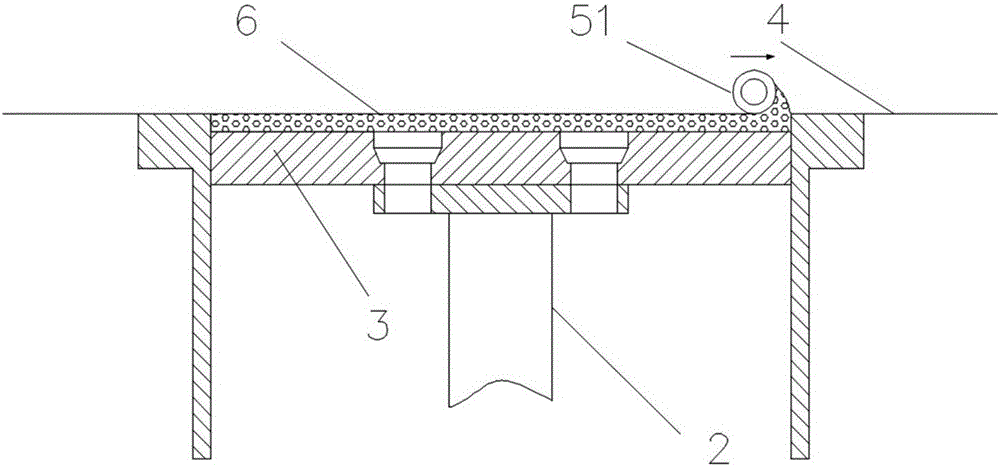

[0064] Different from Example 1, in this example, before the process of casting mold entity preparation, a certain thickness of underlying molding sand is first laid on the powder bed 3 to prevent the subsequent molding sand from sticking to the powder bed 3 during solidification and affecting removal.

[0065] Rapid manufacturing is achieved by spraying solidified sand, specifically the following steps:

[0066] (a) set up a three-dimensional model of the sand mold in the computer, and car...

Embodiment 3

[0074] Configure molding sand covered with xylene sulfonic acid: the particle size of the molding sand is 100-200 mesh, use a sand mixer or other equipment to mix the molding sand and xylene sulfonic acid at a ratio of 100:0.5, that is, the amount of xylene sulfonic acid added is 0.1% by weight of molding sand.

[0075] Configure the diluted phenolic resin: mix the phenolic resin and absolute ethanol with a liquid mixer or other equipment. The weight ratio of the phenolic resin to the absolute ethanol is 100:5, that is, the absolute ethanol accounts for 5% of the phenolic resin.

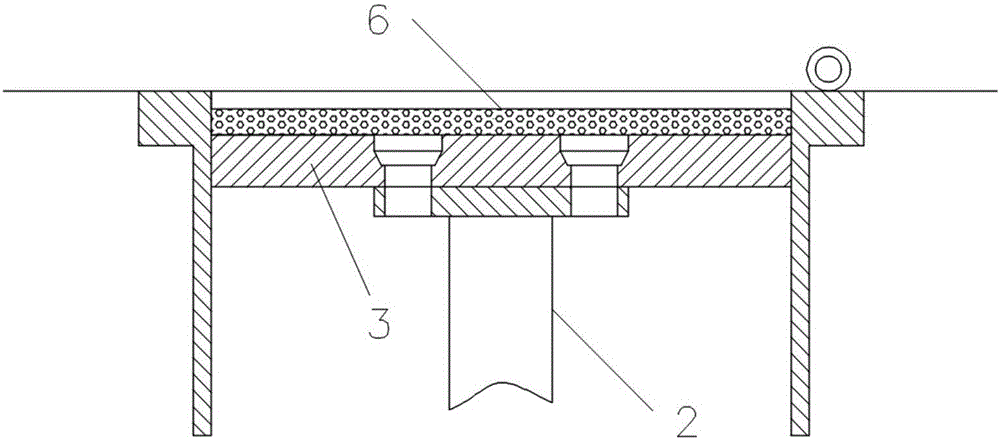

[0076] Rapid manufacturing is achieved by spraying solidified sand, specifically the following steps:

[0077] (a) set up a three-dimensional model of the sand mold in the computer, and carry out layering and data processing on the model; clean up the floating sand on the frame and above of the work surface 4, so that the working area of the molding cylinder 1 range is clean and free of floating sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com