Semiconductor film growth control device and semiconductor film growth control method

A technology for thin film growth and control equipment, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of uncontrollable thin film thickness of semiconductor materials, affecting device performance, and delaying valve switching, etc. Conducive to precise control, improve control accuracy, and reduce the effect of transition layer growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

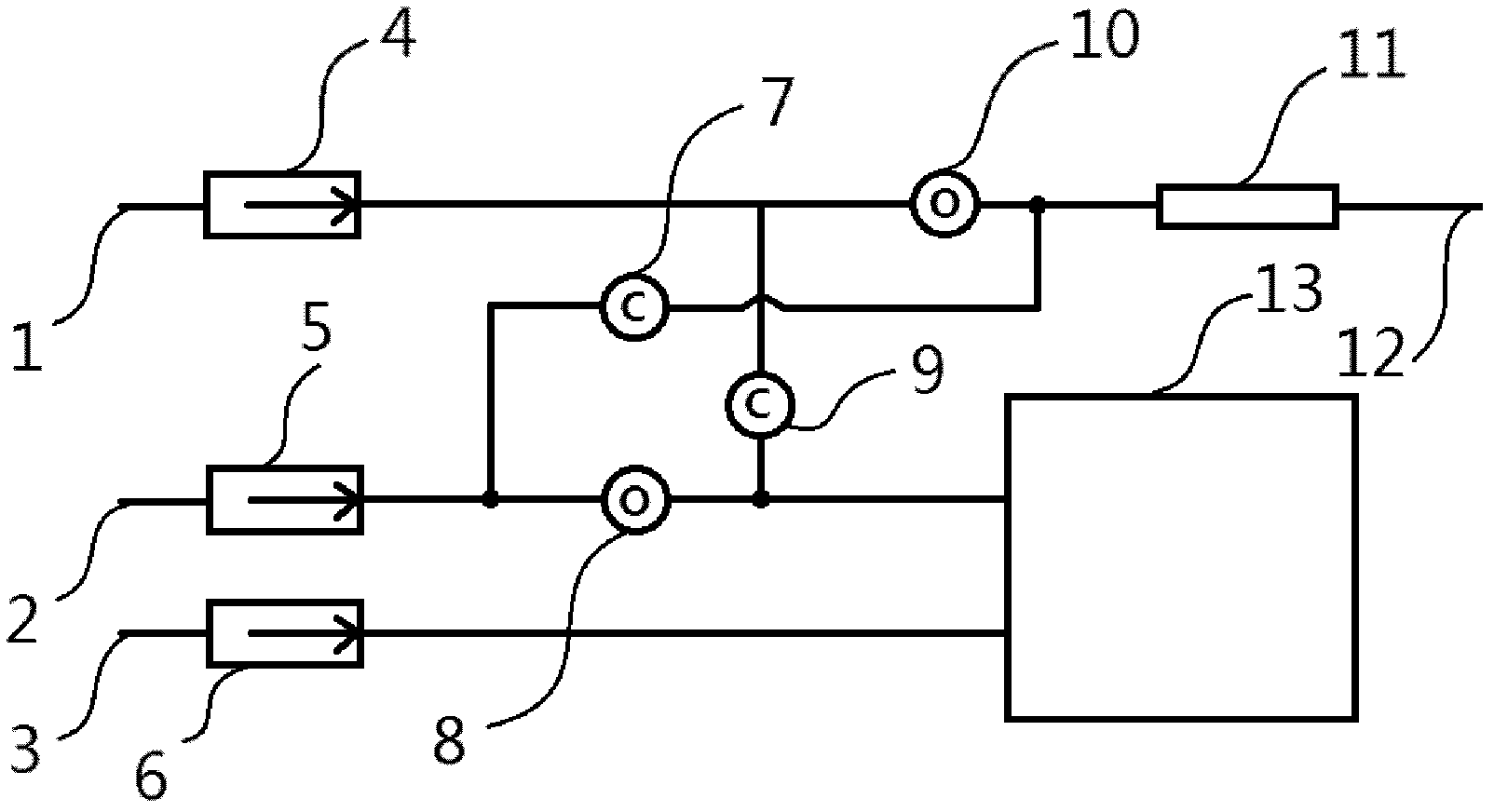

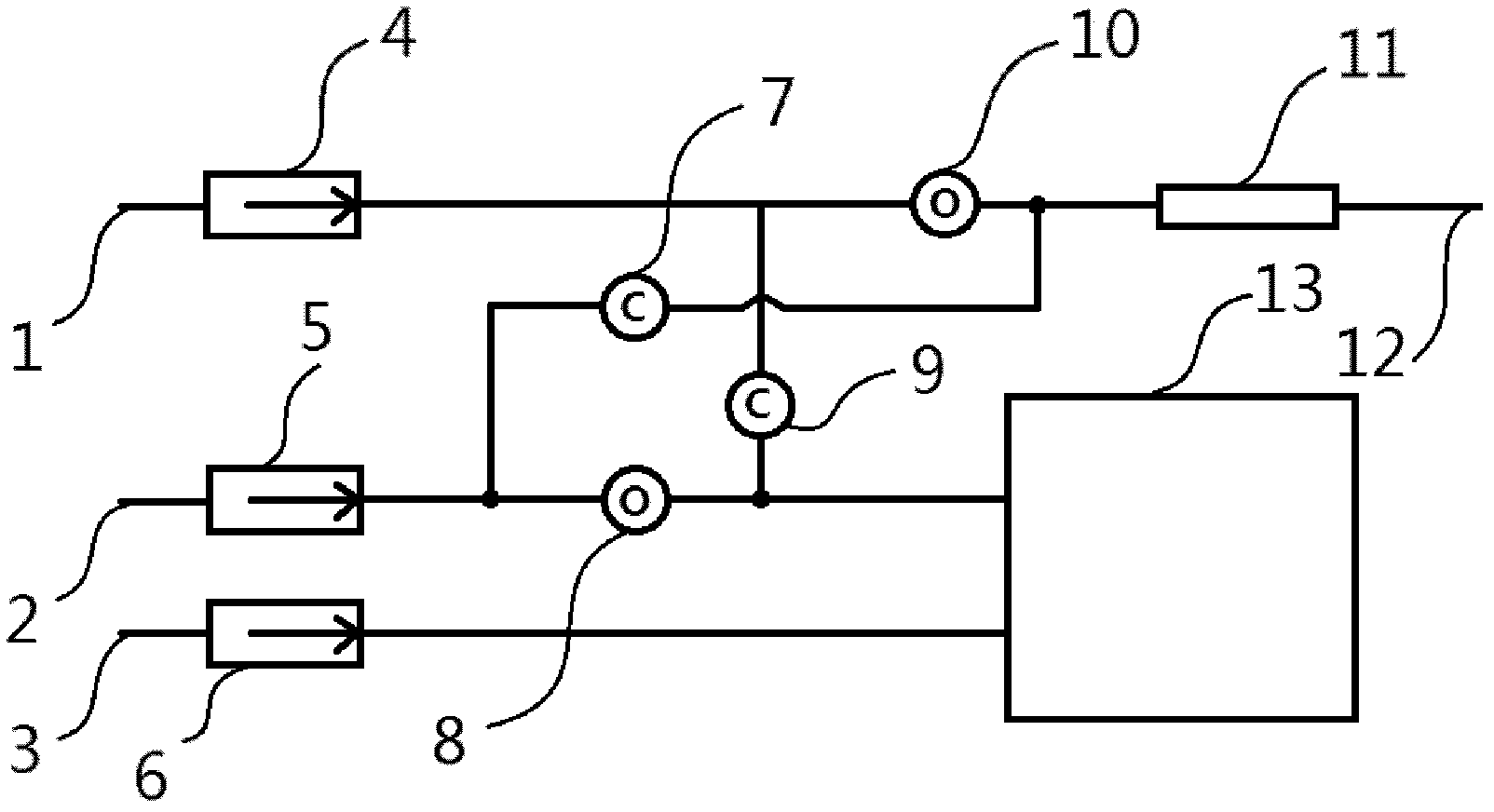

[0028] Such asfigure 1 As shown, in the first process stage, the first inlet pipe 1 is fed into the carrier gas hydrogen, the second inlet pipe is fed into the 2 reaction source trimethylgallium, and the third inlet pipe is fed into the 3 reaction source ammonia; One flow controller 4 is set to 10000 sccm, the second flow controller 5 is set to 10000 sccm, and the third flow controller 6 is set to 20000 sccm; the first branch valve 7 is closed, the second valve 8 is opened, and the second branch valve 9 is closed , the first valve 10 is opened; the trimethylgallium reaction source enters the semiconductor thin film growth reaction chamber 13, and the hydrogen gas enters the first tail gas pipeline 12 for gallium nitride thin film growth; in the second process stage, the first branch valve 7 is opened, The second valve 8 is closed at the same time, the second branch valve 9 is opened, and the first valve 10 is closed simultaneously; the trimethylgallium reaction source in the se...

Embodiment 2

[0030] Such as figure 1 As shown, in the first process stage, the first inlet pipe 1 is fed into the reaction source trimethylaluminum, the second inlet pipe 2 is fed into the reaction source trimethylgallium, and the third inlet pipe 3 is fed into the reaction source Ammonia. The first flow controller 4 is set to 10000 sccm, the second flow controller 5 is set to 10000 sccm, and the third flow controller 6 is set to 20000 sccm, while the first branch valve 7 is closed, the second valve 8 is opened, and the second branch valve 9 is closed, the first valve 10 is opened, trimethylgallium enters the semiconductor film growth reaction chamber 13, and trimethylaluminum enters the first tail gas pipeline 12 to perform gallium nitride film growth; in the second process stage, the first branch valve 7 is opened, the second valve 8 is closed simultaneously, the second branch valve 9 is opened simultaneously, the first valve 10 is closed simultaneously, the trimethylaluminum in the fir...

Embodiment 3

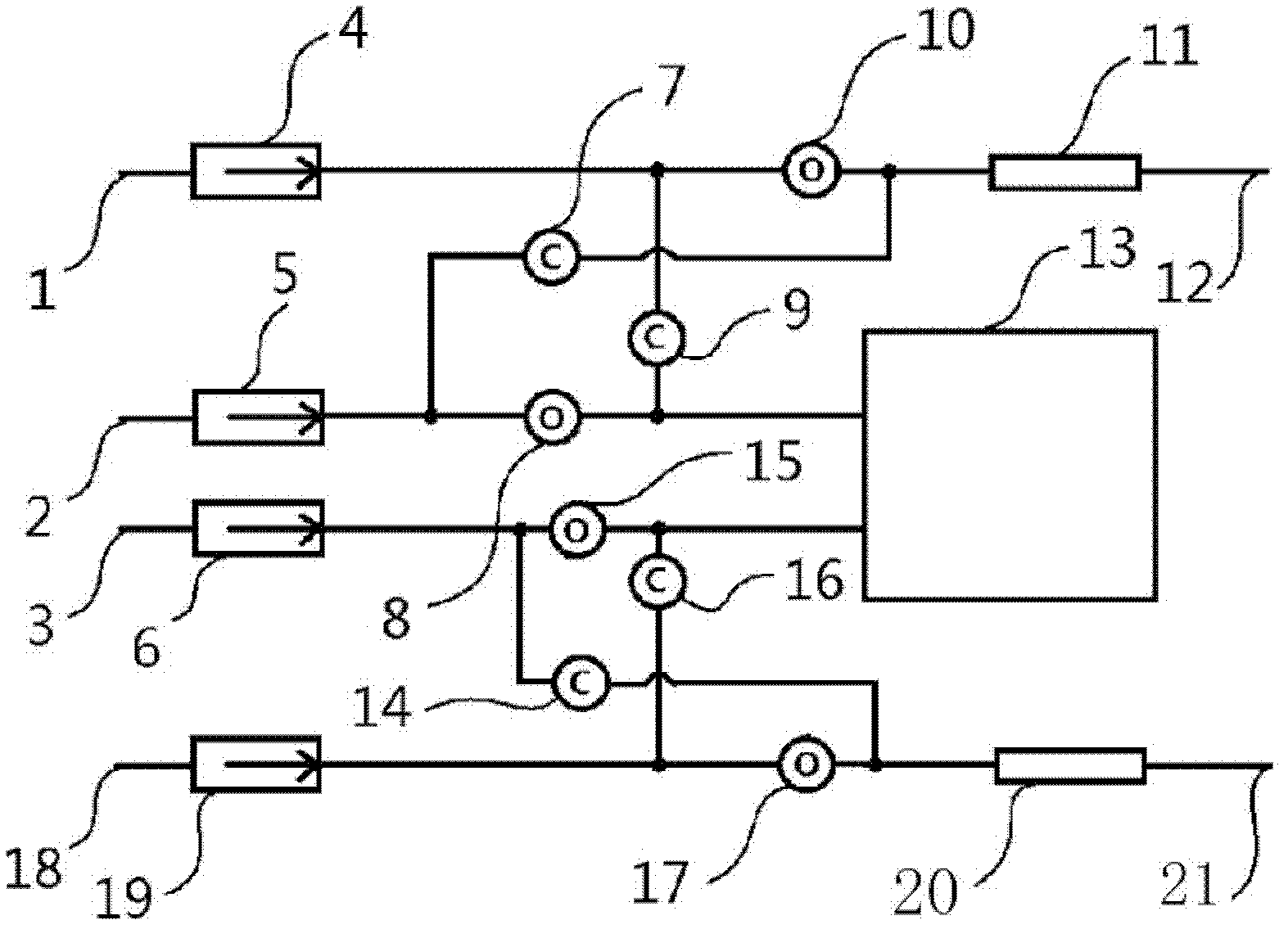

[0032] Such as figure 2 , in the first process stage, the first air intake pipe 1 feeds carrier gas hydrogen, the second air intake pipe feeds 2 reaction source trimethylgallium, the third air intake pipe 3 feeds reaction source ammonia; the fourth road Inlet pipeline 18 feeds hydrogen, the first flow controller 4 is set to 10000sccm, the second flow controller 5 is set to 10000sccm, the third flow controller 6 is set to 20000sccm, and the fourth flow controller 19 is set to 20000sccm; A branch valve 7 is opened, the second valve 8 is opened, the second branch valve 9 is closed, the first valve 10 is opened, the third branch valve 14 is closed, the third valve 15 is opened, the fourth branch valve 16 is closed, and the fourth branch valve is closed. The valve 17 is opened, trimethylgallium and ammonia gas enter the semiconductor film growth reaction chamber 13, and hydrogen gas enters the first tail gas pipeline 12 and the second tail gas pipeline 21 to grow gallium nitride f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com