Preparation process of positive electrode material for sodium ion battery

A technology for sodium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low volume energy density and low active material content, and achieves improved cycle performance, improved fiber-forming ability, and good electrical conductivity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A kind of positive electrode material preparation technology of sodium ion battery, comprises the following steps:

[0027] The first step is the preparation of the precursor sol. Add manganese salt, sodium salt, iron salt and nickel salt to the water. After stirring evenly, add the precipitation inhibitor. After homogenization, the precursor sol is obtained.

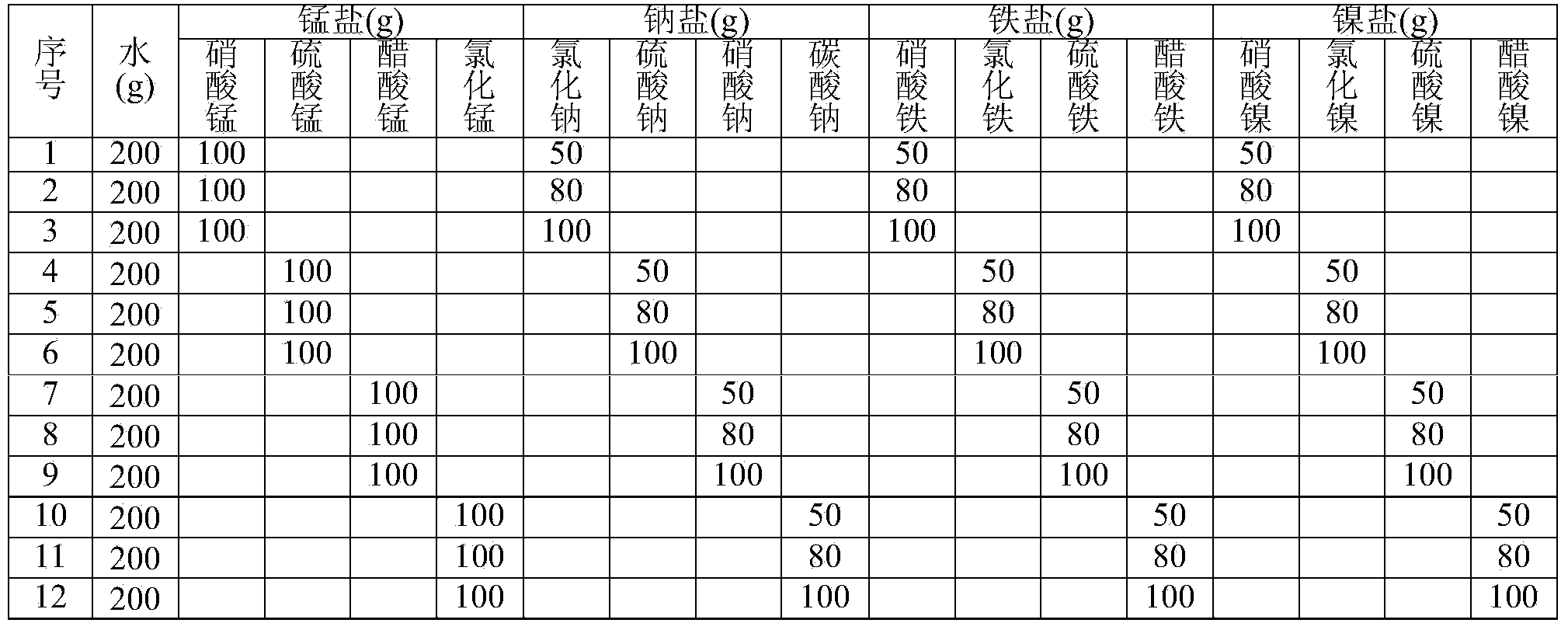

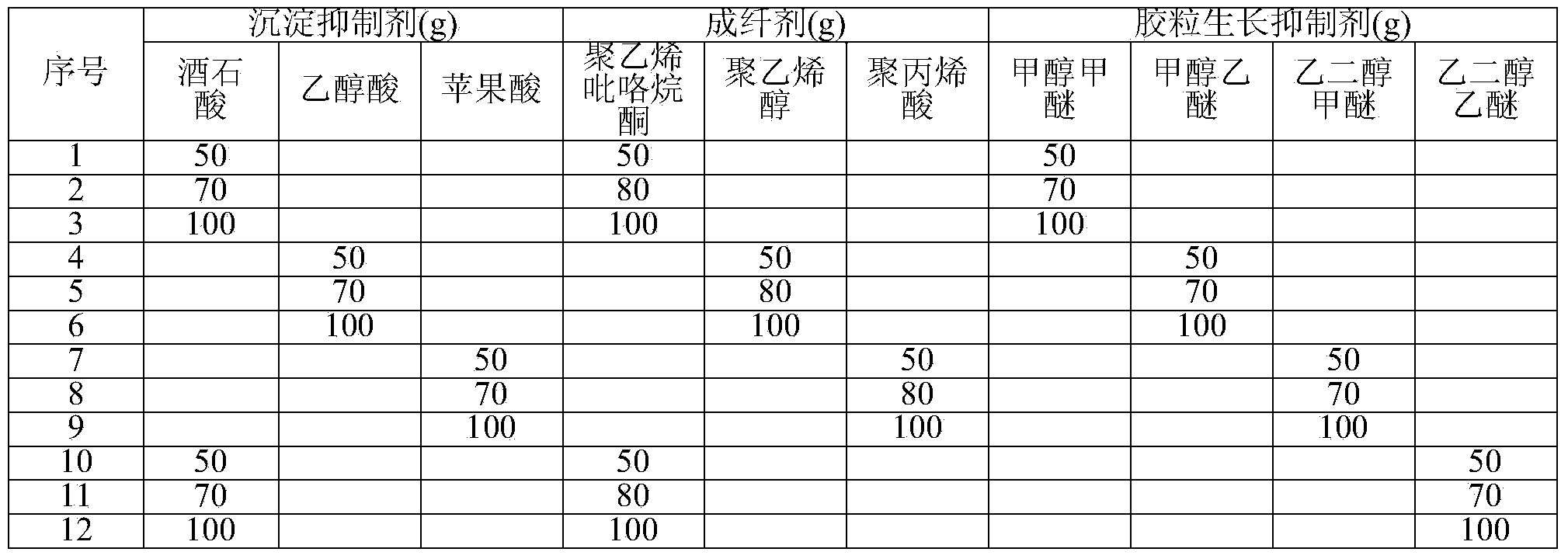

[0028] Table 1 lists the composition of 12 example formulations numbered 1-12. According to the different embodiments in Table 1, the types and addition amounts of manganese salt, sodium salt, iron salt and nickel salt are determined. Table 2 lists the formula composition of precipitation inhibitor, fiber forming agent and colloid growth inhibitor of 12 examples numbered 1-12. According to the different examples in Table 2, the types and addition amounts of the precipitation inhibitor, fiber-forming agent, and micelle growth inhibitor were determined.

[0029] Table 1. Recipe for Salt

[0030]

[0031] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com