Sleeve pipe type low-enriched uranium nuclear fuel assembly

A nuclear fuel assembly and nuclear fuel technology, applied in fuel elements, nuclear engineering, nuclear power generation, etc., can solve problems such as poor bending stiffness and complex manufacturing process of nuclear fuel assemblies, and achieve safe and reliable use, good matching, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

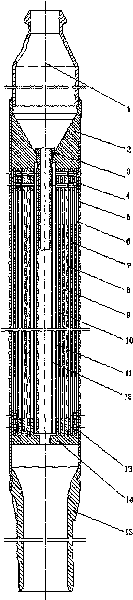

[0021] Such as figure 1 As shown, the casing type low enriched uranium nuclear fuel assembly of the present invention consists of a concentric inner casing 12, an outer casing 5, 6 layers of nuclear fuel casings placed between the inner casing 12 and the outer casing 5, and 6 layers of nuclear fuel The upper end of the casing is fixedly connected, installed on the upper positioning tooth block 2 on the top of the outer casing 5, the upper joint 1 fixed on the upper port of the upper positioning tooth block 2; the lower joint 15 set in the lower port of the outer casing 5, and placed in the outer casing The lower positioning tooth block 14 in the tube 5 is fixedly connected with the lower end of the 6-layer nuclear fuel casing; wherein:

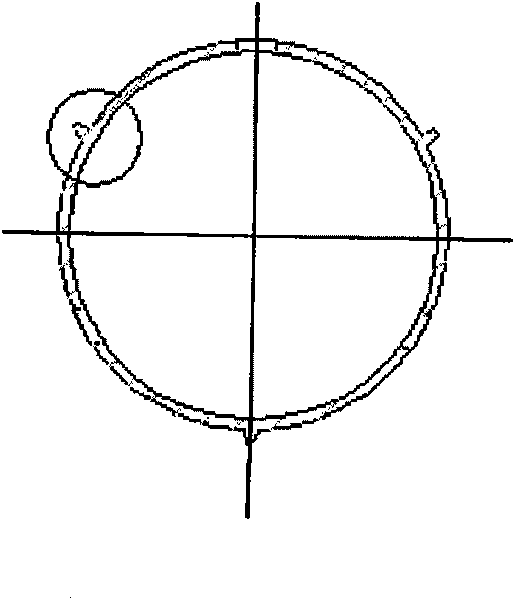

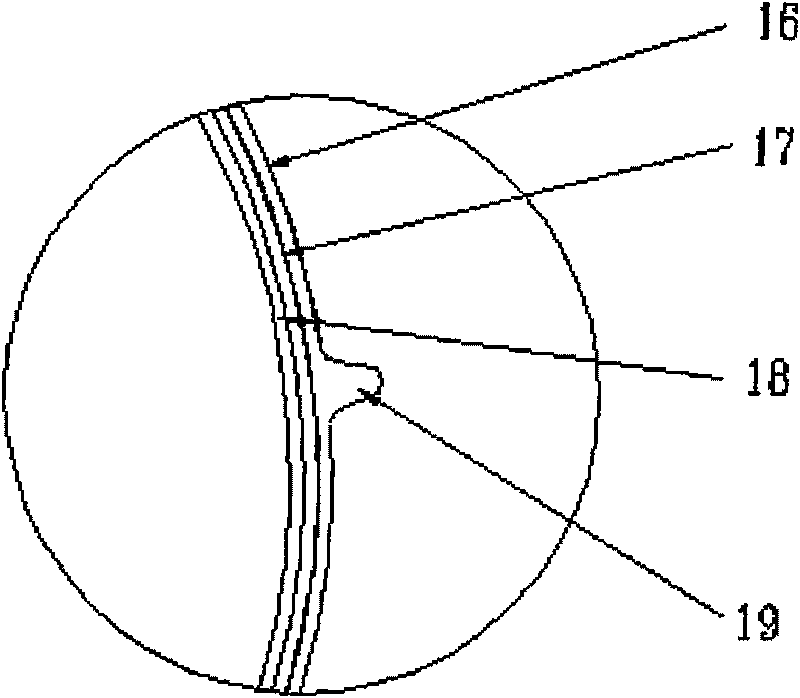

[0022] The upper positioning tooth block 2 has three longitudinal tooth plates 20 that are centrally symmetrical at 120° to position each layer of nuclear fuel sleeves 6-11 on the transverse section, and the lower ends of the tooth plates 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com