Method for separating uranium from uranium ore pulp with electrodialysis method

A technology of electrodialysis and uranium ore, which is applied in the field of separation, purification and enrichment of uranium, can solve problems such as complex process, and achieve the effect of simple process, small footprint and elimination of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

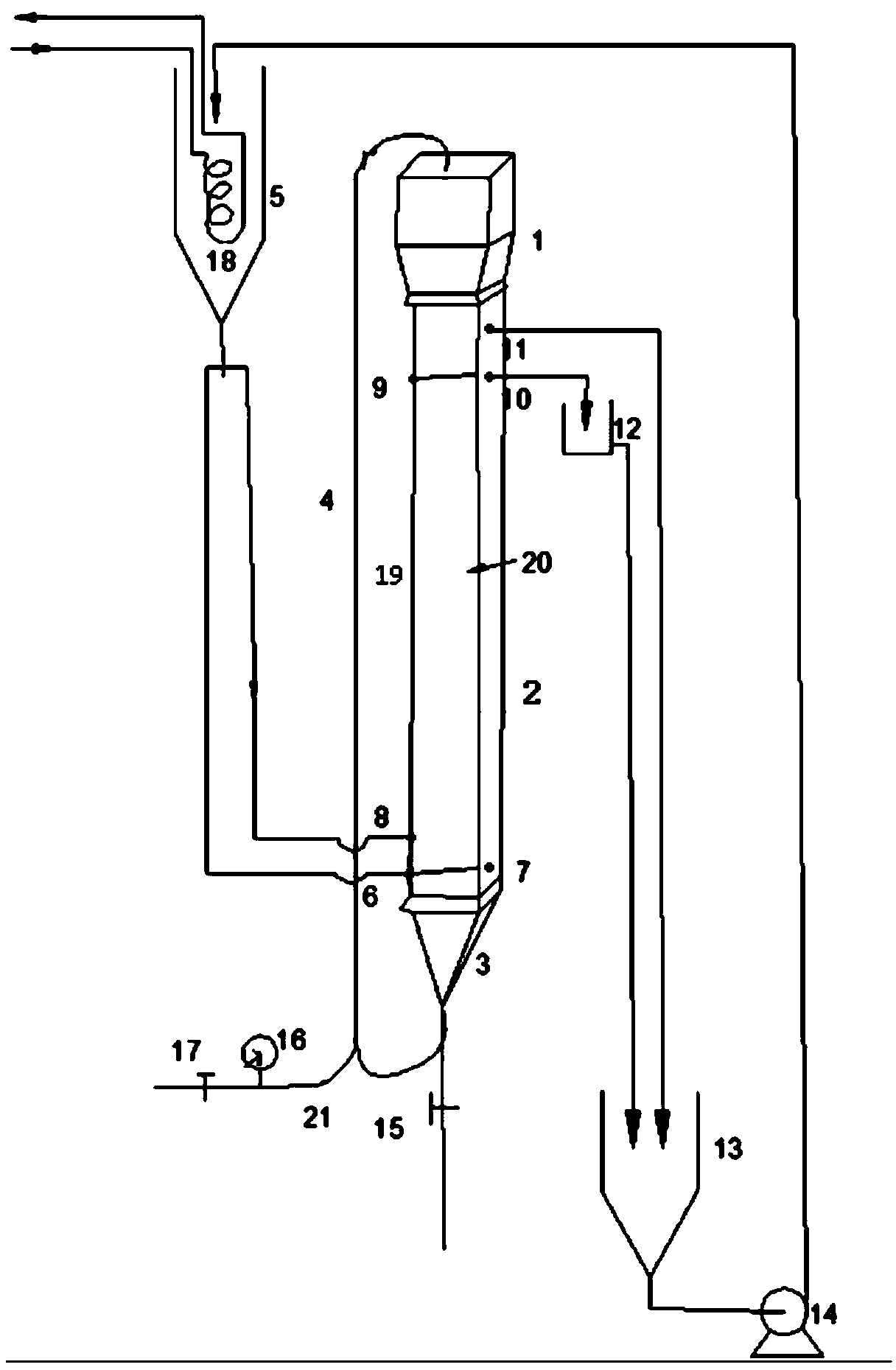

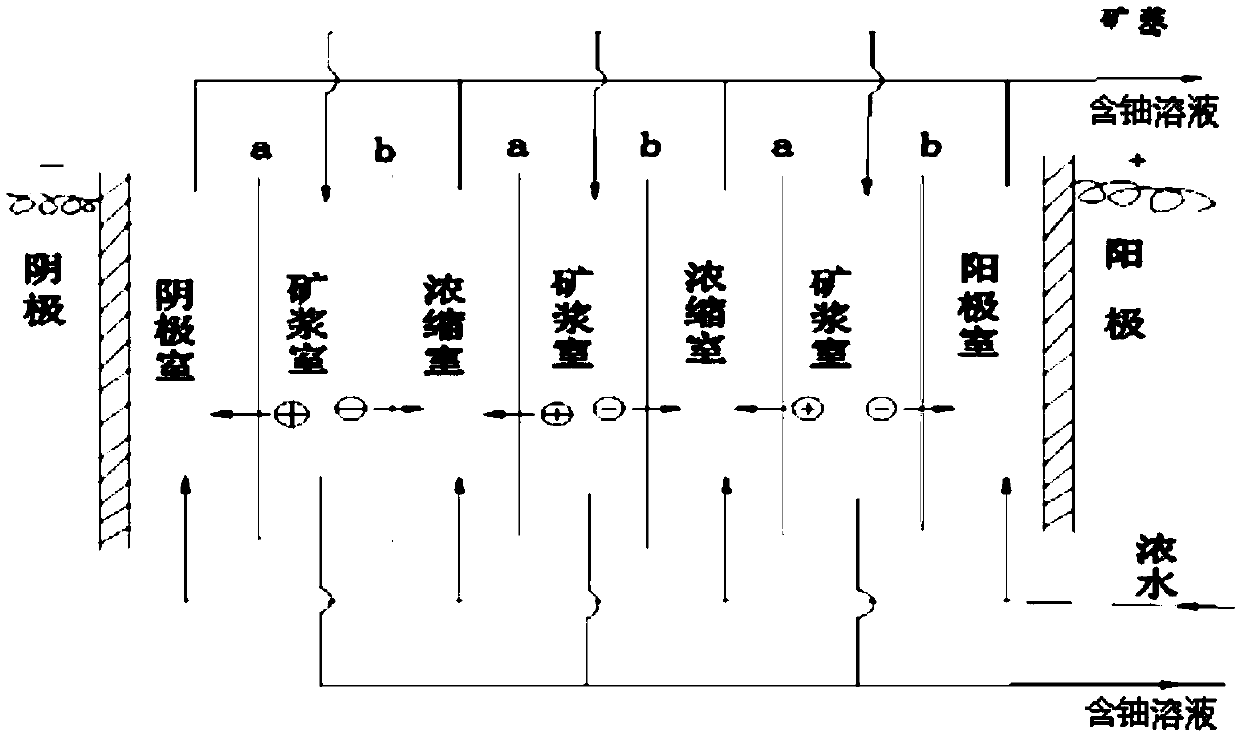

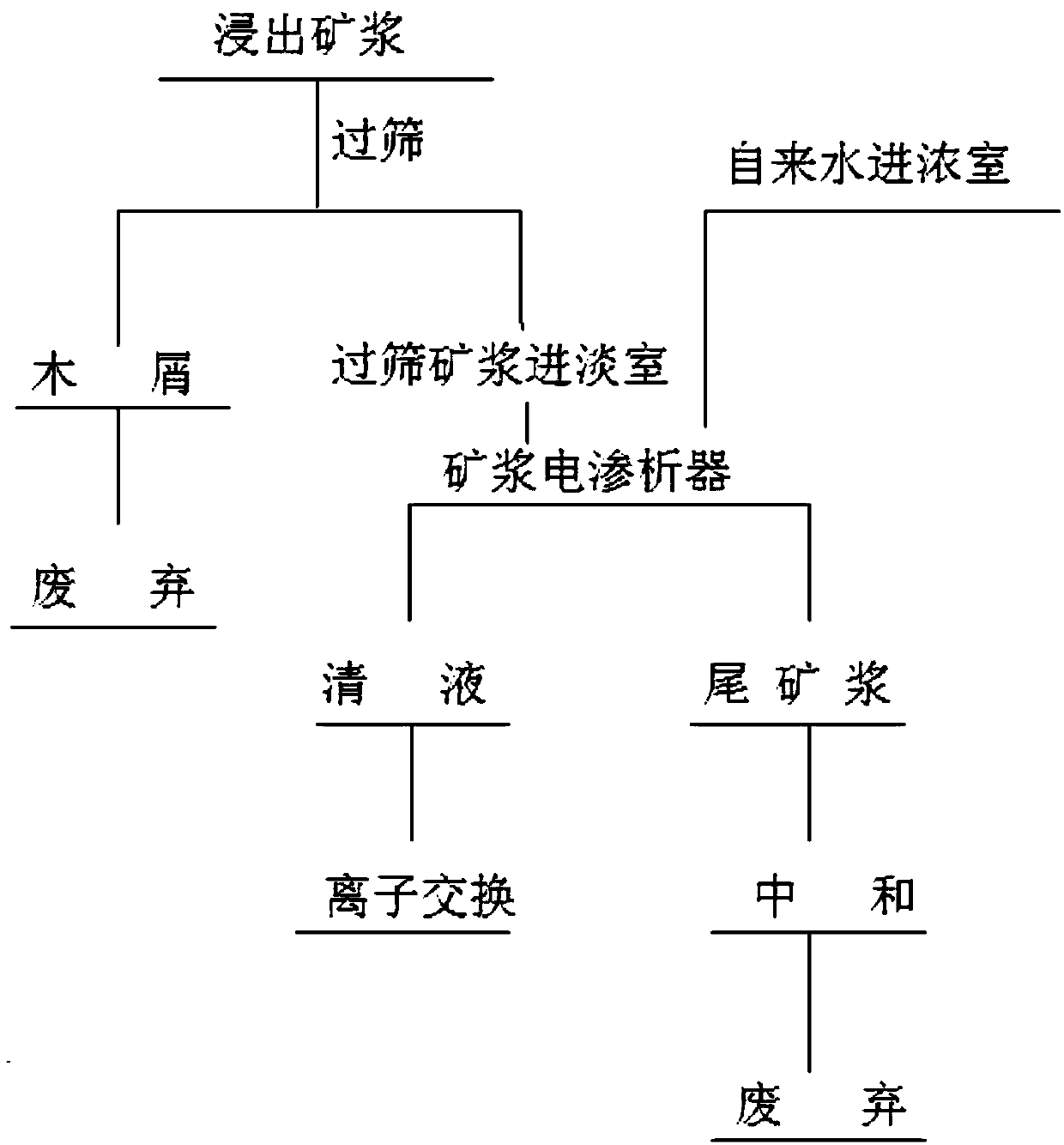

Method used

Image

Examples

Embodiment 1

[0037] Add the uranium ore sample with a particle size of about 200 mesh A and the leaching agent into the leaching tank, the mass ratio of the ore sample and the leaching agent is 1:1, the leaching agent is 50% sulfuric acid solution, the leaching temperature is 40°C, and the stirring and leaching time is 0.5 h, to obtain uranium-containing pulp, the uranium concentration in the uranium-containing pulp is 0.690g / L, and the sulfuric acid is 26.0g / L. Filter out the sawdust and other sundries in the leached uranium-containing pulp with a stainless steel sieve, and then put it into the upper funnel and enter the electrodialyzer. When the U concentration in the leached pulp is greater than 5mg / L, the leached pulp continues to circulate in the pulp electrodialyzer. When the concentration of U in the leached pulp drops below 5mg / L, the tailings are neutralized and discarded. Tap water was used as the initial concentrated water. After each cycle of the concentrated water, the U sol...

Embodiment 2

[0041] Add the B uranium ore sample with a particle size of about 200 mesh and the leaching agent into the leaching tank, the mass ratio of the ore sample and the leaching agent is 1:1, the leaching agent is 50% sulfuric acid solution, the leaching temperature is 40°C, and the stirring and leaching time is 0.5 h, Obtain uranium-containing pulp, the uranium concentration in the uranium-containing pulp is 0.458g / L, and the sulfuric acid is 29.0g / L. Filter out the sawdust and other debris in the leached pulp with a stainless steel sieve, and then put it into the upper funnel and enter the electrodialyzer. When the U concentration in the leached pulp is greater than 5mg / L, the leached pulp continues to circulate in the pulp electrodialyzer. When the concentration of U in the leached pulp drops below 5mg / L, the tailings are neutralized and discarded. Tap water was used as the initial concentrated water. After each cycle of the concentrated water, the U solution in the concentrate...

Embodiment 3

[0045] Add the C uranium ore sample with a particle size of about 200 mesh and the leaching agent into the leaching tank, the mass ratio of the ore sample and the leaching agent is 1:1, the leaching agent is 50% sulfuric acid solution, the leaching temperature is 40°C, and the stirring and leaching time is 0.5 h, to obtain uranium-containing pulp, the uranium concentration in the uranium-containing pulp is 0.445g / L, and the sulfuric acid is 26.2g / L. Filter out the sawdust and other debris in the leached pulp with a stainless steel sieve, and then put it into the upper funnel and enter the electrodialyzer. When the U concentration in the leached pulp is greater than 5mg / L, the leached pulp continues to circulate in the pulp electrodialyzer. When the concentration of U in the leached pulp drops below 5mg / L, the tailings are neutralized and discarded. Tap water was used as the initial concentrated water. After each cycle of the concentrated water, the U solution in the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com