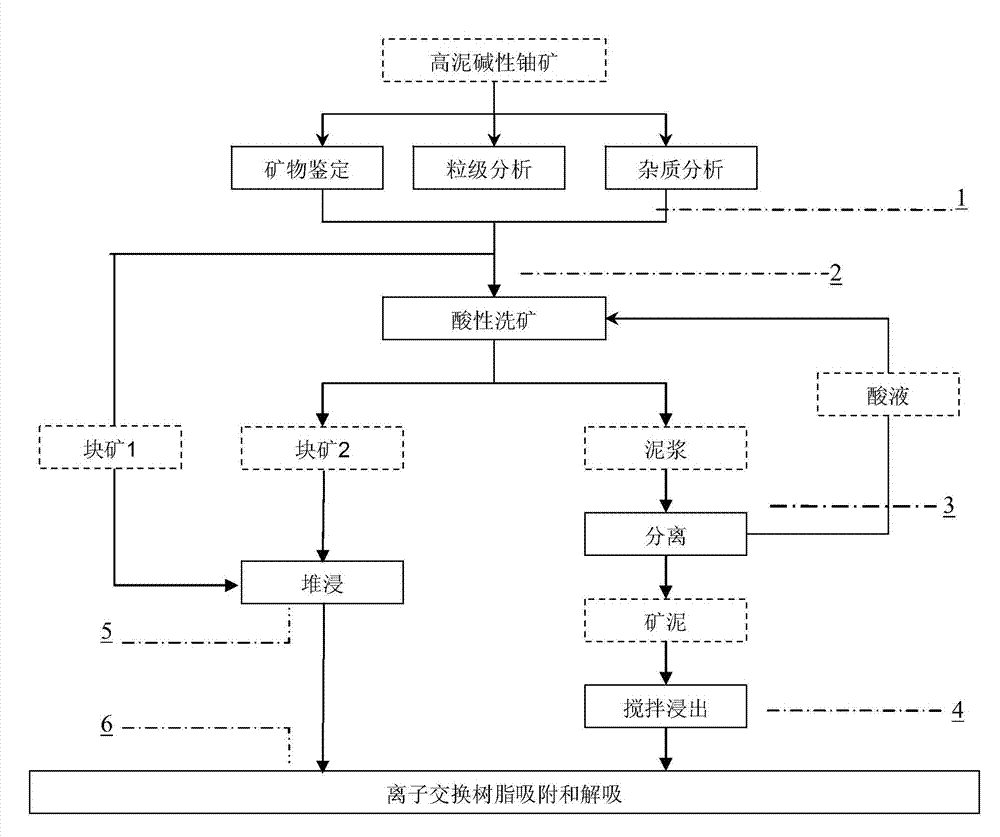

Acid ore washing biological leaching process used for high mud alkaline uranium ore

A technology for biological leaching and ore washing, applied in the field of uranium ore acid washing and leaching technology, can solve the problems of deteriorating leaching effect and leaching index, slow leaching speed of uranium ions, poor ore heap permeability, etc., so as to solve the problems of poor heap leaching permeability, Low cost and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The process of the present invention is applied to a certain alkaline uranium ore in the central and southern regions of my country. The ore is identified as crystalline uranium ore and pitchblende uranium ore; gangue minerals are mainly clay minerals, feldspar alterations and a small amount of sericin Mica and carbonate minerals. The content of uranium in the ore is about 0.2%, FeO 0.75%, CaO 3.86%, MgO 1.39%, SiO 2 79.85%, Al 2 o 3 1.56%, K 2 O 3.10%. The main components of impurities are calcium magnesium oxide and silicate. Particle size analysis showed 80% mineral content at +0.074mm and 20% at -0.074mm. The acid washing process involved in the present invention is suitable for this mineral.

[0047] 1. Ore pretreatment: The raw ore is crushed and screened by the jaw crusher, the ore with a grain size of +30mm is directly sent to the stockyard for stacking, and the ore with a grain size of -30mm enters the acid washing system.

[0048] 2. The basic uranium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com