Freely combined low enriched uranium foil target with multiple single pieces

A combined, foil target technology, used in fuel elements, reactor fuel elements, instruments, etc., can solve the problems of increased target volume, in-stack irradiation, and difficulty in target transportation, target-making and target-removal process, etc. The effect of radiation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] For water-cooled reactors with a temperature of about 100°C, aluminum is the most widely used heat release element shell material, and the 6061LT6 aluminum tube with stronger hardness is selected as the heat release element shell material. The diameter of the reactor irradiation tunnel is basically 70-80mm, and the following exemplary multi-single-piece free combination low Enriched uranium foil target.

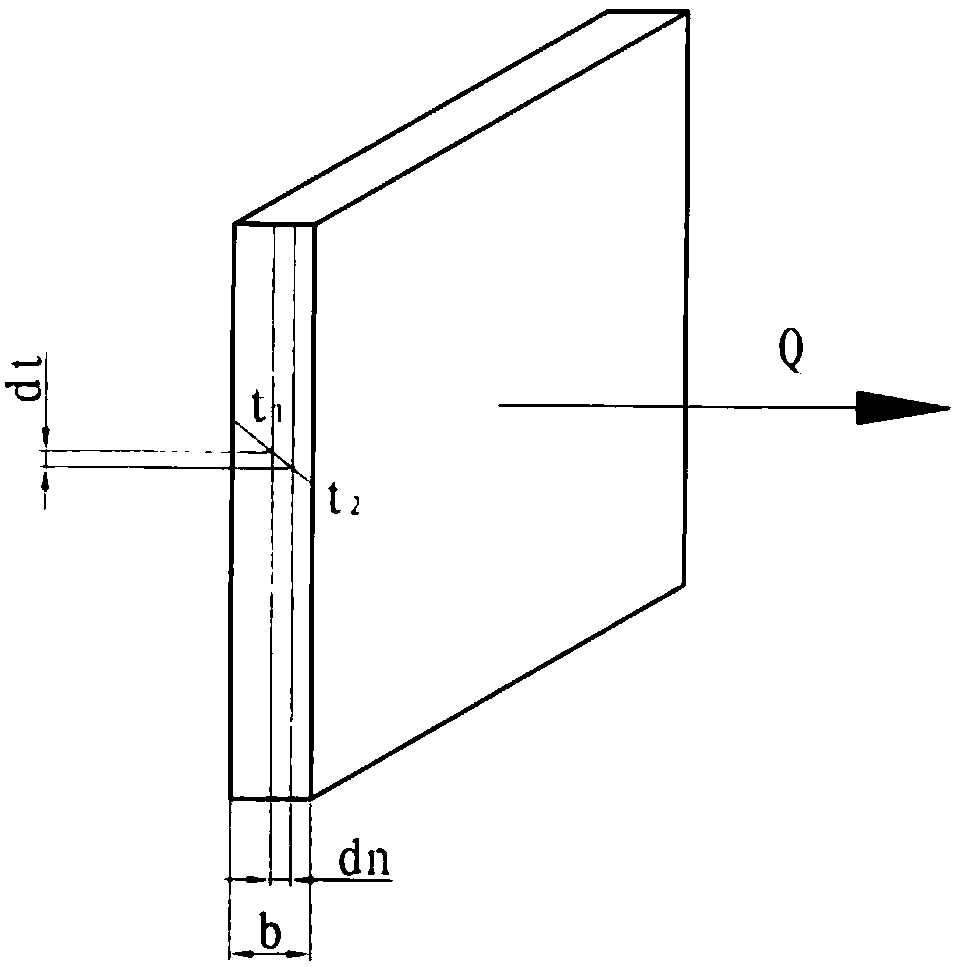

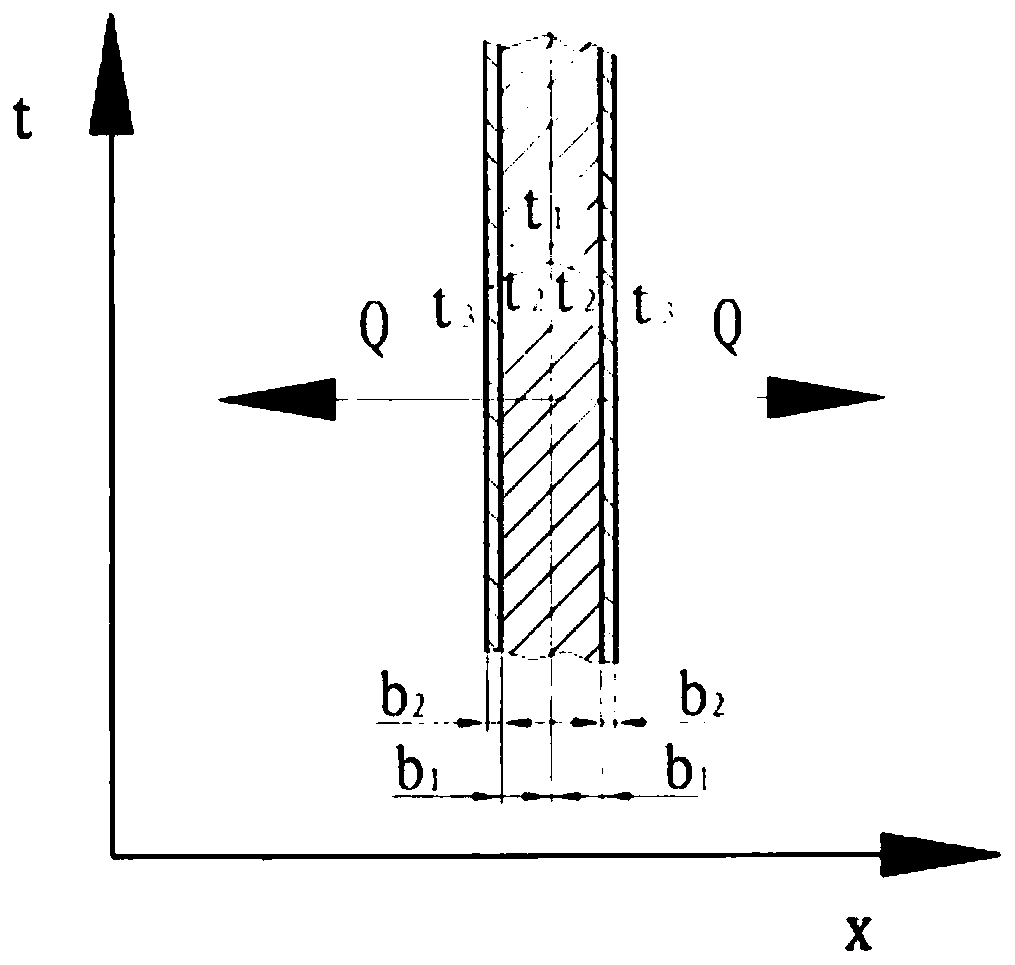

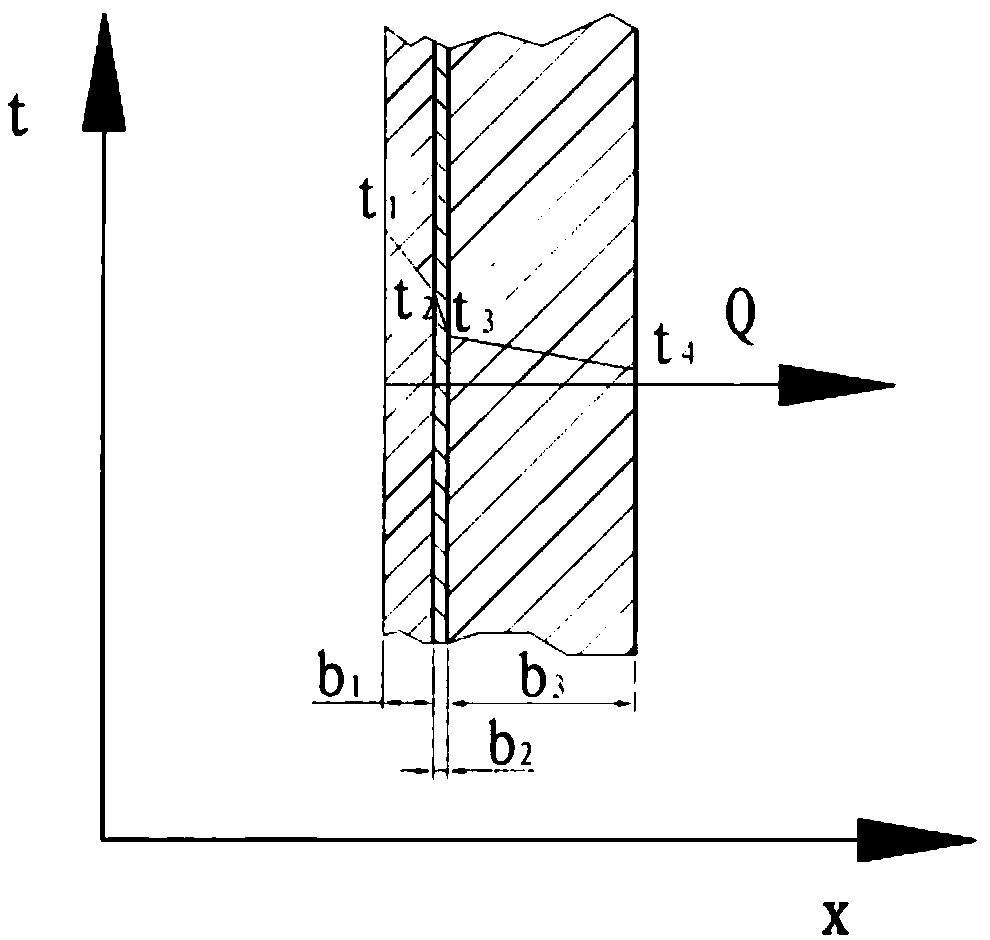

[0131] The structure of the exemplary multi-single-piece freely combined low-enriched uranium foil target of the present invention is as follows Figure 1-2 As shown, it includes a target cylinder 1, a target core plug 2, a low-enriched uranium uranium foil 3, a press plug 4, and a sealing cover 5.

[0132] Hollow aluminum target tube 1 (outer diameter 56mm, thickness 2mm, height 100mm, placed low enriched uranium uranium foil 3 section height 85.44mm) by putting aluminum target plug 2 to make multiple pieces of low enriched uranium freely combined The uranium-uraniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com