Comprehensive experiment loop system for working medium forced circulation of heat conduction oil

A technology of experimental loop and forced circulation, which is applied in the field of comprehensive experimental loop system of forced circulation of heat-conducting oil working fluid, can solve the problems such as difficulty in building core and pipeline convective heat transfer experiment, flow resistance experiment platform of key equipment, and lack of accuracy of measuring instruments, etc. , to achieve the effect of reducing the difficulty of operation and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

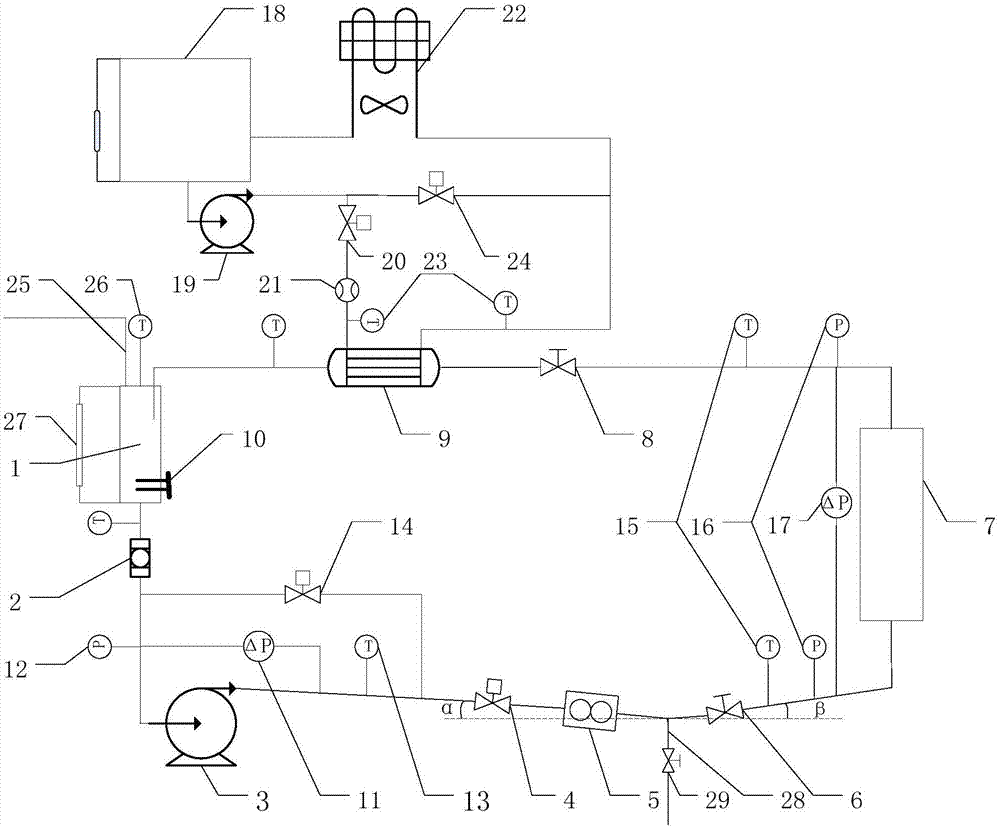

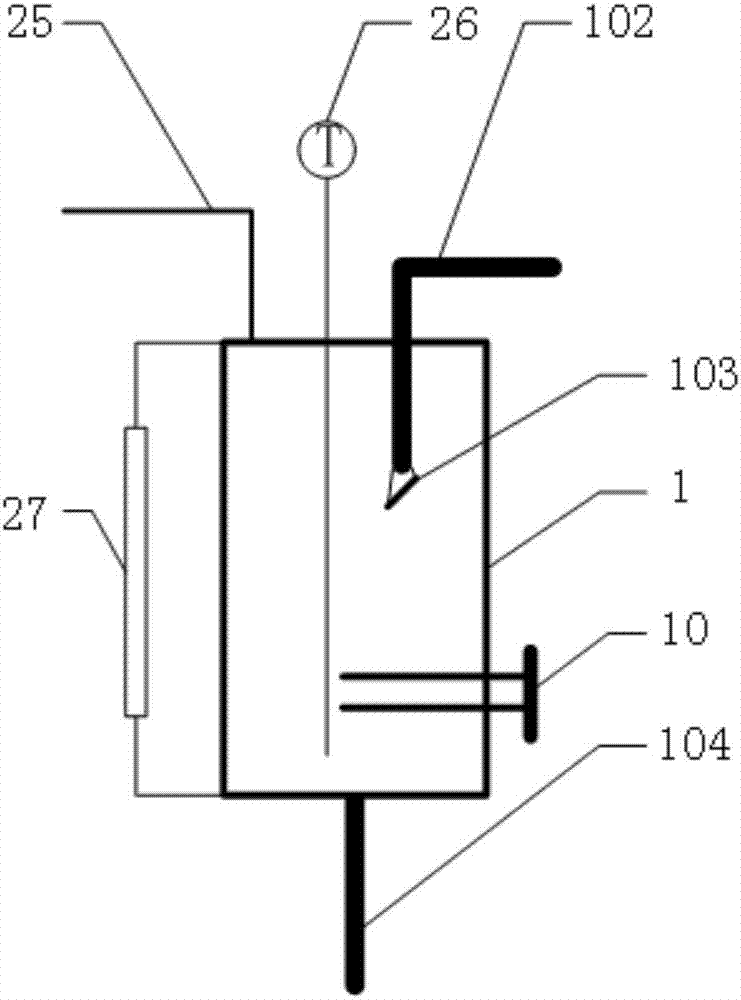

[0037] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0038]Since the heat transfer oil Dowherm‐A has similar physical properties to FLiBe at a lower temperature (75°C), and the dimensionless numbers are equal, it can be used to simulate the flow and heat transfer characteristics of FLiBe, and the heat transfer oil is used as the working medium to carry out flow heat transfer experiments in molten salt reactors Compared with the experiment conducted with high-temperature molten salt FLiBe working medium with a temperature as high as 700 °C, it is obvious that the difficulty of experimental operation is greatly reduced, while the measurement accuracy is greatly improved.

[0039] Based on the use of D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com