Method for detecting cell breakage rate of rolled leaves

A technology for cell fragmentation and detection methods, applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems affecting the health of experimental operators, experimental errors, environmental pollution, etc., to improve experimental safety and speed up. Analyze speed, human and environmental friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

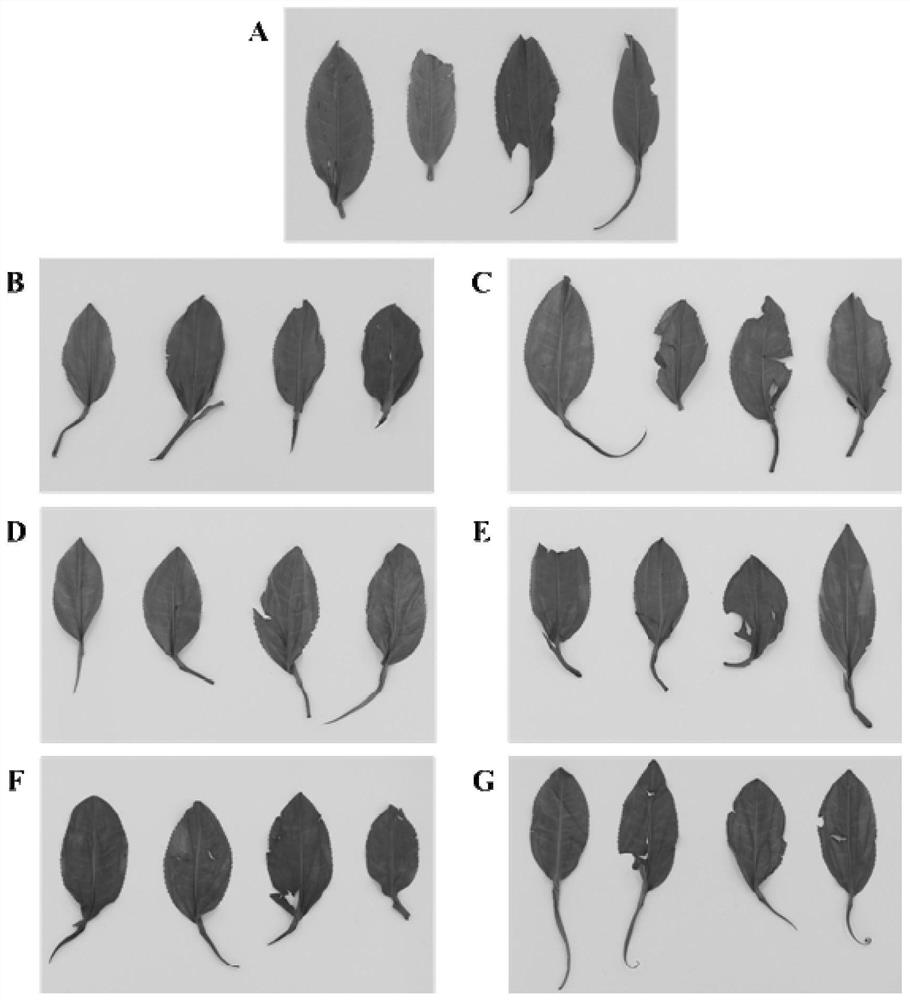

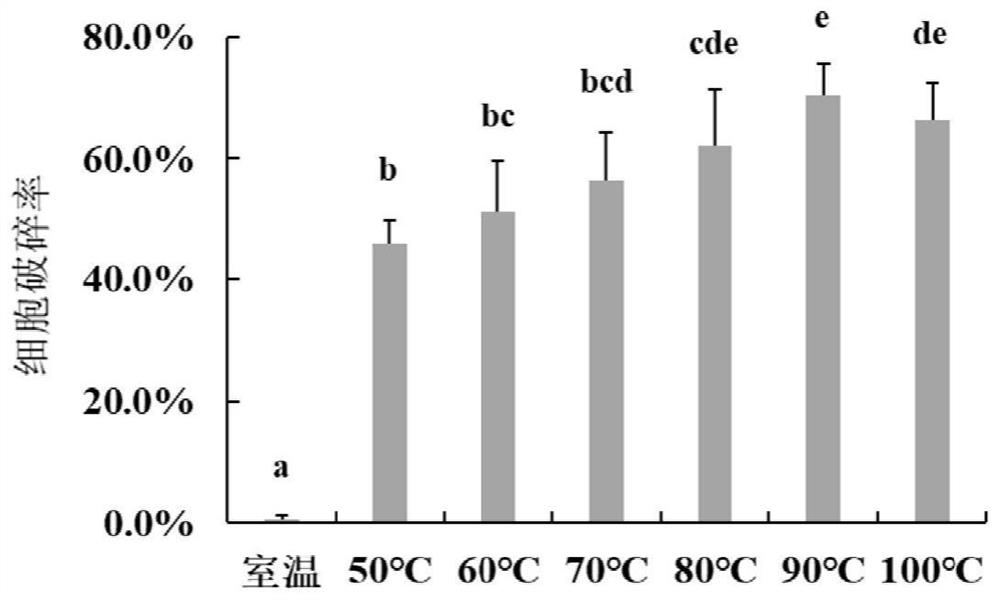

[0034] 1) Use one bud and two leaves of the tea tree variety Yinghong No. 9 as raw materials for black tea processing, take 3-5 grams of black tea leaves after the same batch of primary kneading, and perform water bath treatment. The water bath temperatures are normal temperature, 50°C, and 60°C. , 70°C, 80°C, 90°C, 100°C, the processing time is 1 minute;

[0035] 2) Gently unfold the processed black tea leaves, wipe off the excess water on the surface of the black tea leaves, and then spread the black tea leaves on a white background board or white paper (if necessary, use a glass plate, an empty beaker, etc.) and similar items to flatten black tea leaves, which must be removed before taking pictures);

[0036] 3) Under a stable light source, take pictures of the rolled leaves of black tea (see figure 2 );

[0037] 4) Use a computer to analyze the photos to obtain the cell disruption rate:

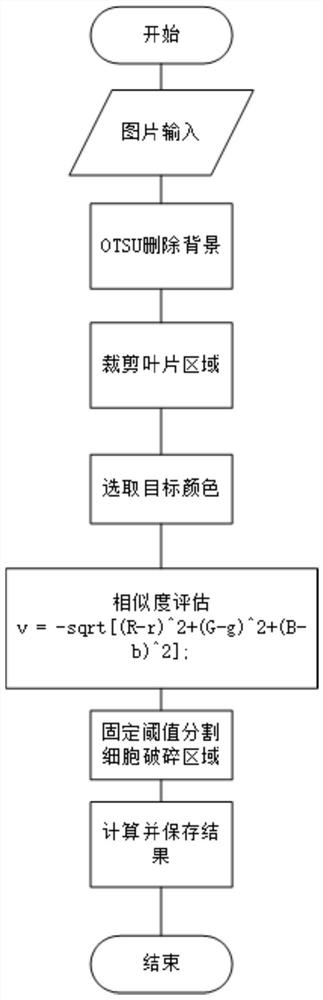

[0038] (a) Import the photo into the computer; (b) use the OTSU method to delete ...

Embodiment 2

[0041] 1) Use one bud and two leaves of the tea tree variety Yinghong No. 9 as raw materials for black tea processing, take 3-5 grams of black tea leaves after the same batch of primary kneading, and perform water bath treatment. The water bath temperatures are normal temperature, 50°C, and 60°C. , 70°C, 80°C, 90°C, and 100°C, the processing time is 1 minute, 3 minutes, and 5 minutes, respectively.

[0042] 2) Gently unfold the processed black tea leaves, wipe off the excess water on the surface of the black tea leaves, and then spread the black tea leaves on a white background board or white paper (if necessary, use a glass plate, an empty beaker, etc.) and similar items to flatten black tea rolling leaves, which must be removed before taking pictures)

[0043] 3) Under a stable light source, take pictures of the rolled leaves of black tea;

[0044] 4) Use a computer to analyze the photos to obtain the cell disruption rate:

[0045] (a) Import the photo into the computer; (...

Embodiment 3

[0051] 1) To process black tea with one bud and two leaves of the tea tree variety Yinghong No. 9 as raw materials, take 3-5 grams of the same batch of withered leaves, rolled leaves after initial rubbing, and twisted leaves after re-kneading respectively, and carry out water bath treatment at 95°C (1min);

[0052] 2) Gently unfold the treated withered leaves, the first-kneaded kneaded leaves and the re-kneaded kneaded leaves to obtain the leaves, wipe off the excess water on the surface of the leaves, and then lay the leaves flat on a white background board or white paper (If necessary, the leaves can be flattened with the help of glass plates, empty beakers, etc., which must be removed before taking pictures)

[0053] 3) Under a stable light source, take pictures of the leaves (see Figure 4 );

[0054] 4) Use a computer to analyze the photos to obtain the cell disruption rate:

[0055] (a) Import the photo into the computer; (b) use the OTSU method to delete the backgrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com